| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

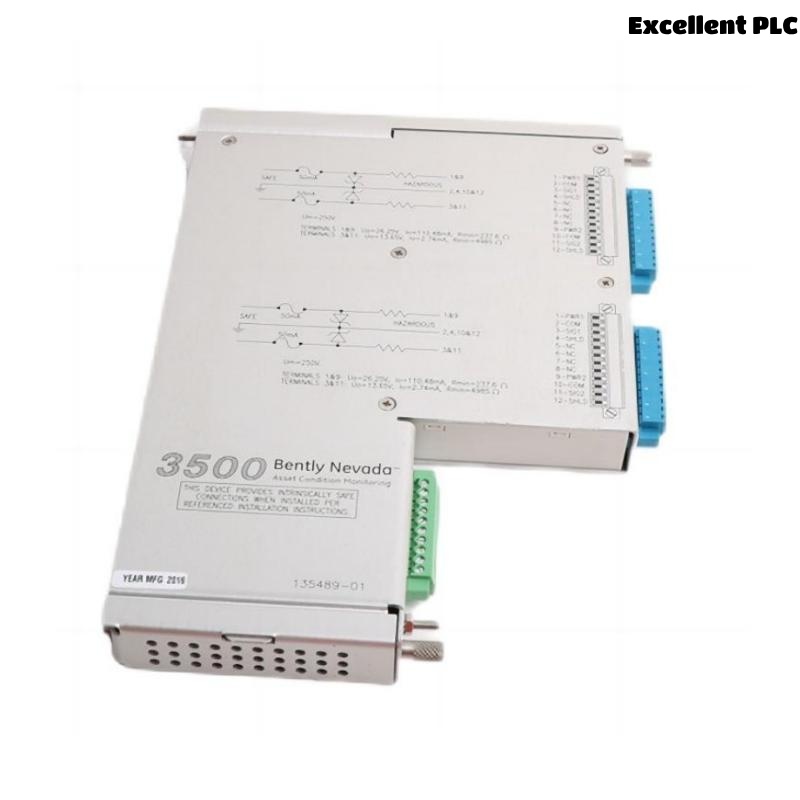

The Bently Nevada 3500/42M-05-00 135489-02 is an advanced seismic monitoring I/O module designed for precise vibration and seismic measurements in industrial environments. This module is a critical component in the Bently Nevada 3500 series, offering superior performance for machinery monitoring by detecting low-frequency and high-frequency vibrations, as well as seismic activity that could indicate potential machinery issues.

The 3500/42M-05-00 module is equipped with advanced signal conditioning technology, which processes seismic data in real time to ensure highly accurate measurements. This module is engineered for use in complex environments, such as power generation plants, offshore oil platforms, manufacturing lines, and other industries that require continuous monitoring of critical machinery to prevent failures and extend equipment life.

The module’s features include a wide range of input and output options, a broad seismic frequency range, and compatibility with the Bently Nevada monitoring systems, ensuring seamless integration into existing monitoring setups. With its ability to detect early signs of failure, the module significantly reduces the risk of unexpected downtime and costly repairs.

Product Parameters

| Parameter | Value |

|---|---|

| Dimensions (L x W x H) | 241.3 × 24.4 × 163.1 mm |

| Weight | 0.46 kg |

| Operating Voltage | 24 V DC |

| Seismic Frequency Range | 0.1 Hz to 10 kHz |

| Signal Output | 4-20 mA, 0-10 V |

| Temperature Range | -40°C to +85°C |

| Mounting Type | Rail-mounted |

| Input Type | Differential / Single-ended |

| Compliance | CE, UL certified |

Applications

The Bently Nevada 3500/42M-05-00 seismic monitoring I/O module is designed for use in a variety of industrial applications where detecting seismic activity and machinery vibrations is crucial for maintaining optimal equipment performance. Some of the key applications include:

-

Power Generation: The module is used in power plants to monitor turbines, compressors, pumps, and other critical equipment. Early detection of vibration or seismic activity helps prevent unexpected failures and ensures continuous power generation.

-

Oil & Gas: The module plays an essential role in monitoring the health of equipment in oil and gas facilities, both onshore and offshore. By tracking seismic events and vibrations in real time, the module assists in preventing catastrophic failures and operational downtime.

-

Manufacturing and Automation: In manufacturing facilities, the module continuously monitors machinery such as motors, conveyor belts, and robotic arms, providing valuable insights into the health of industrial equipment.

-

Mining: In mining operations, the module is used to monitor the condition of heavy-duty machinery like crushers, mills, and grinders. Detecting seismic events can help identify early signs of equipment degradation, ensuring that maintenance is carried out before major issues arise.

-

Transportation and Marine: The module is utilized in monitoring equipment aboard marine vessels, trains, and other transportation systems, where vibration data is critical to ensuring the safety and performance of engines, pumps, and other vital machinery.

-

Industrial Infrastructure: Used in large-scale infrastructure projects to monitor seismic vibrations that may indicate structural concerns, helping maintain the integrity of bridges, dams, and other critical structures.

Advantages

-

High-Precision Monitoring: The 3500/42M-05-00 module offers highly accurate seismic and vibration measurements, allowing for the early detection of machinery faults, ensuring that maintenance can be performed before a failure occurs.

-

Wide Frequency Range: The module’s seismic frequency range of 0.1 Hz to 10 kHz allows it to monitor a wide variety of equipment, capturing both low and high-frequency vibrations.

-

Flexible Output Options: It supports both 4-20 mA and 0-10 V output, making it compatible with a wide range of industrial control systems and instrumentation.

-

Robust Temperature Performance: With an operational temperature range of -40°C to +85°C, the module can perform reliably in even the harshest industrial environments, from cold storage facilities to hot process plants.

-

Easy Integration: The module is designed to easily integrate into existing Bently Nevada 3500 series monitoring systems, reducing installation time and ensuring seamless communication between devices.

-

Compact and Lightweight: At just 0.46 kg and with compact dimensions, the module is easy to install in space-constrained environments while still providing robust monitoring capabilities.

-

Signal Conditioning: Built-in signal conditioning ensures that seismic data is clean and accurate, leading to more reliable diagnostics and decision-making.

-

Extended Equipment Life: Continuous monitoring of vibrations and seismic activity helps extend the operational life of equipment by identifying potential issues early, before they lead to major failures.

FAQs

-

What seismic frequency range does the 3500/42M-05-00 module cover?

The module has a seismic frequency range of 0.1 Hz to 10 kHz, making it capable of detecting both low and high-frequency seismic events. -

What is the weight of the 3500/42M-05-00 module?

The module weighs 0.46 kg, making it lightweight and easy to handle during installation. -

What are the output options for the 3500/42M-05-00?

The module supports both 4-20 mA and 0-10 V outputs, providing flexibility for integration with various monitoring systems. -

What is the operating temperature range of the 3500/42M-05-00 module?

It operates in a temperature range of -40°C to +85°C, ensuring reliable performance in extreme conditions. -

Can the 3500/42M-05-00 module be mounted easily?

Yes, it is designed for rail mounting, making installation straightforward and efficient. -

What is the input type of the module?

The module supports both differential and single-ended inputs for flexibility in connecting to a wide range of sensors. -

What industries benefit from using the 3500/42M-05-00 module?

It is used in industries such as power generation, oil & gas, mining, manufacturing, and marine, among others. -

Is the 3500/42M-05-00 module compliant with safety standards?

Yes, it is CE and UL certified, ensuring that it meets international safety and quality standards. -

How does the module help prevent equipment failure?

By continuously monitoring seismic activity and vibration, the module detects early signs of equipment degradation, allowing for timely maintenance and reducing the risk of unexpected downtime. -

Is the module compatible with existing Bently Nevada systems?

Yes, the 3500/42M-05-00 module seamlessly integrates with the Bently Nevada 3500 series, ensuring smooth operation within existing setups.

Recommended Models (Same Series or Related Models)

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/42M | Seismic monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/41 | Vibration monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/44 | Dynamic vibration monitor | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/45 | Rotor monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/46 | Expansion module for seismic monitoring | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/47 | Temperature and vibration module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

Popular Bently Nevada Models

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/45-01-01 | Keyphasor® vibration monitor module | 150 x 120 x 90 mm | 1.2 kg |

| 3500/45-01-CN | Keyphasor® vibration monitor module (China version) | 150 x 120 x 90 mm | 1.2 kg |

| 3500/45-02-00 | Keyphasor® module with extended range and features | 150 x 120 x 90 mm | 1.3 kg |

| 3500/45-01-02 | Advanced Keyphasor® vibration monitoring module | 150 x 120 x 90 mm | 1.3 kg |

| 3500/45-02-01 | Enhanced Keyphasor® with diagnostic capabilities | 150 x 120 x 90 mm | 1.4 kg |

| 3500/45-02-CN | Keyphasor® module for China region with extended features | 150 x 120 x 90 mm | 1.3 kg |

Excellent PLC

Excellent PLC