| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

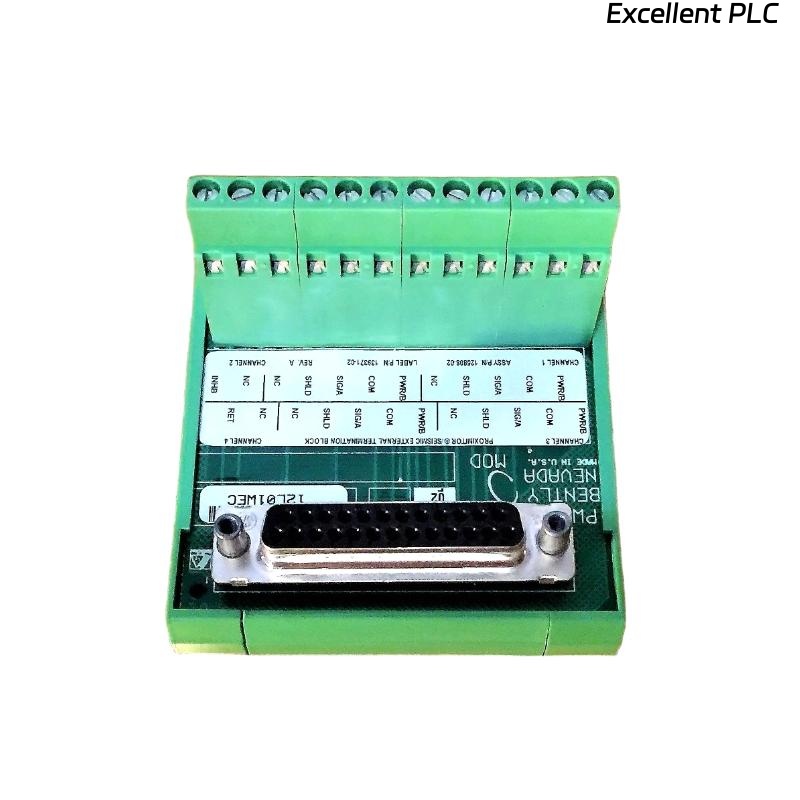

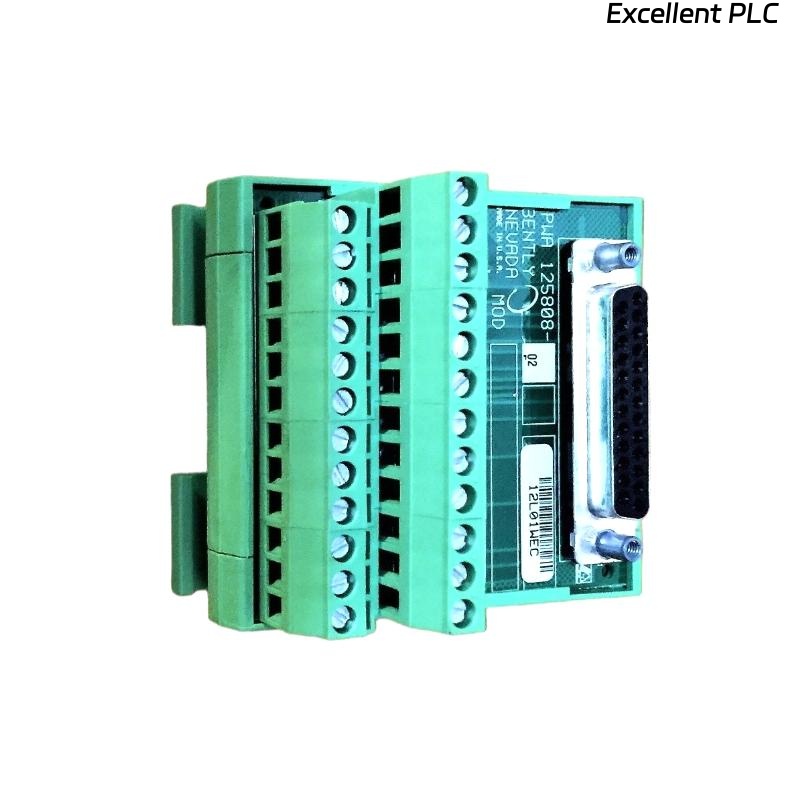

The Bently Nevada 3500/42M 125808-02 Proximitor Seismic External Block Terminal is part of the widely recognized 3500 Machinery Protection System, designed to provide advanced vibration monitoring and machinery protection. This module is specifically engineered to interface with proximity probes and seismic transducers, enabling precise measurement of shaft vibration, casing vibration, and rotor dynamics.

The “M” in 42M indicates a modernized version of the classic 3500/42 module, offering enhanced capabilities for industrial environments. With the External Block Terminal (EBT) design, the module provides simplified wiring, increased flexibility, and greater ease of maintenance during installation. It delivers continuous online monitoring, enabling predictive maintenance and reducing the risk of catastrophic equipment failure in critical turbomachinery such as turbines, compressors, motors, and generators.

Product Specifications

| Parameter | Details |

|---|---|

| Model Number | 3500/42M 125808-02 |

| Product Type | Proximitor/Seismic Monitor with External Block Terminal |

| System Compatibility | Bently Nevada 3500 Monitoring System |

| Input Channels | 4 independent channels (Proximitor or Seismic) |

| Supported Transducers | Proximity probes, Proximitor sensors, seismic vibration transducers |

| Measurement Parameters | Shaft vibration, casing vibration, acceleration, velocity, displacement |

| Signal Processing | Digital signal conditioning with programmable filters |

| Alarm Setpoints | 2 configurable alarm levels per channel (Alert and Danger) |

| Output Options | 4–20 mA proportional outputs, relay outputs through 3500/32 module |

| Termination Type | External Block Terminal (EBT) |

| Power Consumption | < 7 Watts (from 3500 rack backplane) |

| Operating Temperature | -30 °C to +65 °C |

| Storage Temperature | -40 °C to +85 °C |

| Humidity | Up to 95% non-condensing |

| Compliance & Certifications | CE, CSA, ATEX, IECEx |

| Dimensions (H × W × D) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/42M 125808-02 is deployed across industries where machinery reliability and uptime are critical:

-

Steam and Gas Turbines: Provides accurate monitoring of shaft and casing vibration.

-

Compressors and Pumps: Detects imbalance, misalignment, and bearing issues in real-time.

-

Electric Generators and Motors: Ensures reliability by monitoring both shaft dynamics and casing vibration.

-

Petrochemical & Refinery Equipment: Protects critical assets in hazardous environments.

-

Condition Monitoring Systems: Works as part of the 3500 rack to provide online machinery diagnostics and predictive maintenance data.

Product Advantages

The 3500/42M 125808-02 provides numerous technical and operational benefits:

-

Versatile Monitoring: Supports both Proximitor and seismic transducers across four channels.

-

Advanced Signal Processing: Digital filters ensure accurate vibration and displacement measurements.

-

Integrated Alarming: Dual alarm levels per channel allow early detection and emergency response.

-

Flexible Wiring: External Block Terminal (EBT) simplifies connections, reducing wiring complexity.

-

Seamless Integration: Works natively within the 3500 system for comprehensive machinery protection.

-

Compliance with Standards: Certified for use in hazardous industrial environments.

-

High Reliability: Designed for 24/7 continuous monitoring in mission-critical applications.

-

Scalability: Expandable to larger monitoring systems within the 3500 rack infrastructure.

FAQ

-

How many channels does the 3500/42M 125808-02 support?

It supports four independent input channels for Proximitor or seismic sensors. -

What types of transducers can be connected to this module?

It is compatible with proximity probes, Proximitor sensors, and seismic vibration transducers. -

Does the module provide alarm functionality?

Yes, each channel has two configurable alarm levels: Alert and Danger. -

What is the primary difference between the 42M and the older 42 module?

The 42M features enhanced digital signal processing, expanded flexibility, and improved noise immunity. -

How does the External Block Terminal benefit installation?

EBT simplifies wiring, making installation faster and reducing the risk of connection errors. -

Can the module output proportional signals for external systems?

Yes, it provides 4–20 mA outputs proportional to the vibration measurements. -

How is the module powered?

It receives power directly from the 3500 system rack backplane, requiring no external supply. -

What diagnostic features are available?

The module includes built-in self-tests, channel health monitoring, and input validation. -

How does it support predictive maintenance?

By continuously monitoring shaft and casing vibration, it helps identify imbalance, misalignment, or bearing wear before failures occur. -

Is the module certified for use in hazardous industrial environments?

Yes, it is ATEX and IECEx certified, allowing deployment in explosive atmospheres.

Recommended Related Models (Same Series/Category)

| Model | Description |

|---|---|

| 3500/40M | Proximitor Monitor Module (shaft vibration monitoring) |

| 3500/44M | Aeroderivative Gas Turbine Vibration Monitor |

| 3500/46M | Hydro Radial Vibration Monitor |

| 3500/22M | Transient Data Interface Module |

| 3500/25 | Isolated Keyphasor I/O Module |

| 3500/32M | Relay Module for alarm and trip functions |

Popular Models from Bently Nevada (Same Brand)

| Model | Description |

|---|---|

| 3500/05 | System Rack for 3500 Series |

| 3500/93 | System Display Interface Module |

| 330103-00-05-10-02-00 | Proximity Probe Assembly |

| 330180-50-05 | Extension Cable for Proximity Probes |

| 3300 XL Proximitor | Proximity Transducer for vibration and position monitoring |

| 7200 Series Monitors | Legacy machinery protection monitors |

Excellent PLC

Excellent PLC