| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

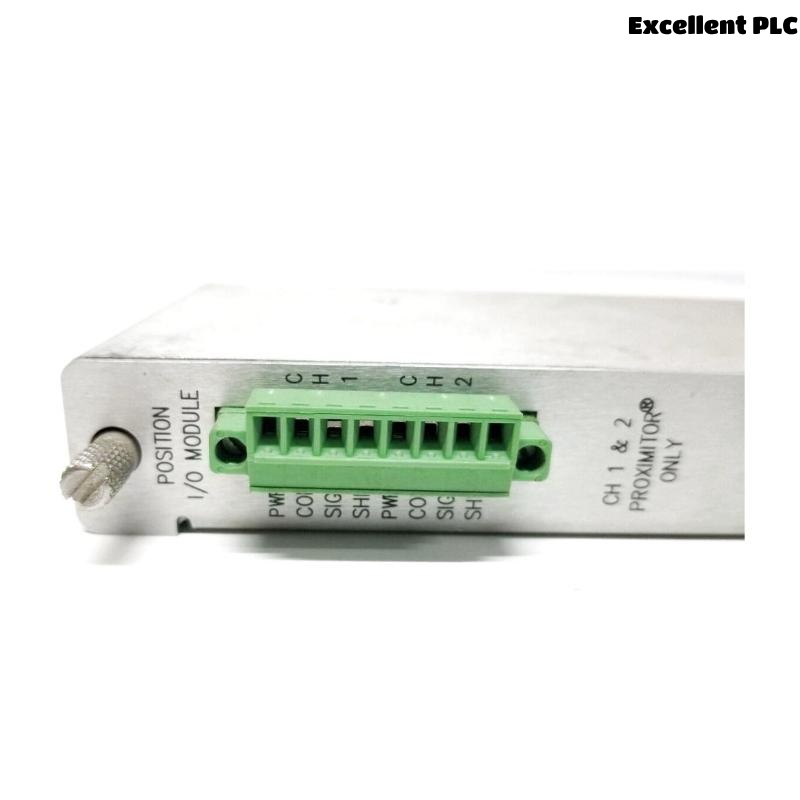

The Bently Nevada 3500/45-01-00 135137-01 Position Monitoring I/O module is a highly reliable and efficient component designed for tracking the position of critical rotating equipment in industrial environments. This module is a vital part of Bently Nevada’s 3500 series, providing continuous monitoring of position parameters like displacement, distance, or angular position.

With its advanced signal processing and real-time data acquisition capabilities, the 3500/45-01-00 module helps ensure that rotating machinery such as turbines, compressors, motors, and pumps are always operating within their specified tolerances. The module enables early detection of misalignments, abnormal wear, and other potential issues that could lead to costly downtime or machinery failures.

This device is specifically designed to integrate seamlessly with the Bently Nevada 3500 series monitoring systems, providing a comprehensive solution for the continuous health monitoring of critical machinery components. The module’s flexibility and robust performance in demanding environments make it ideal for industries such as power generation, oil & gas, and heavy manufacturing.

Product Parameters

| Parameter | Value |

|---|---|

| Dimensions (L x W x H) | 241.3 × 24.4 × 99.1 mm |

| Weight | 0.2 kg |

| Operating Voltage | 24 V DC |

| Signal Output | 4-20 mA, 0-10 V |

| Temperature Range | -40°C to +85°C |

| Mounting Type | Rail-mounted |

| Input Type | Differential / Single-ended |

| Compliance | CE, UL certified |

Applications

The Bently Nevada 3500/45-01-00 module is designed for applications in industrial environments where monitoring the position of rotating equipment is critical. Key applications include:

-

Power Generation: In power plants, this module is used to monitor turbines, pumps, and motors, ensuring that their position remains within safe operational limits.

-

Oil & Gas: On offshore platforms and in refineries, the module tracks the position of critical equipment such as pumps, compressors, and drilling equipment, ensuring early detection of wear and misalignment.

-

Mining: It is used to monitor the position of heavy-duty mining equipment, such as crushers and conveyor systems, helping prevent damage caused by misalignment or mechanical failure.

-

Manufacturing: In manufacturing plants, the module helps monitor machinery such as motors, conveyors, and robotic arms, ensuring smooth and safe operations.

-

Transportation: The module is used in monitoring the positioning of propulsion systems and rotating components in trains, marine vessels, and aircraft engines, contributing to enhanced operational reliability.

-

Industrial Infrastructure: In critical infrastructure projects, it ensures the proper alignment of equipment in large-scale projects such as dam construction, bridges, and tunnels.

Advantages

-

High Precision: The 3500/45-01-00 provides highly accurate position monitoring, ensuring that machinery components are operating within their specified tolerances.

-

Versatile Output: The module supports both 4-20 mA and 0-10 V output, which makes it compatible with a variety of industrial control systems.

-

Wide Temperature Range: Operating from -40°C to +85°C, the module is built to perform in harsh industrial environments, whether in extreme heat or cold.

-

Compact Design: With compact dimensions (241.3 × 24.4 × 99.1 mm) and a lightweight build (0.2 kg), the module is easy to install and integrate into space-constrained systems.

-

Seamless Integration: It easily integrates into the Bently Nevada 3500 series systems, providing a unified and reliable monitoring solution for critical machinery.

-

Early Fault Detection: By monitoring position parameters, the module helps detect misalignment or abnormal wear before they lead to machinery failure, minimizing downtime and repair costs.

-

Durable and Robust: Built to withstand harsh environments, the module is designed to operate reliably in manufacturing plants, oil rigs, and other demanding industrial locations.

-

Cost-Effective: With its ability to prevent machinery failures and optimize operational efficiency, this module contributes to significant cost savings by reducing unplanned downtime and repair expenses.

FAQs

-

What is the function of the 3500/45-01-00 module?

The module tracks the position of rotating equipment, such as turbines, pumps, and motors, to detect misalignments and abnormal wear. -

What is the weight of the 3500/45-01-00 module?

The module weighs 0.2 kg, making it lightweight and easy to integrate into systems. -

What are the output options for this module?

It provides 4-20 mA and 0-10 V outputs, offering flexibility in integration with various control systems. -

What is the operating temperature range of the 3500/45-01-00?

The module operates in a wide temperature range from -40°C to +85°C, suitable for harsh environments. -

How does the 3500/45-01-00 help prevent machinery failure?

By continuously monitoring the position of rotating components, the module detects misalignment and other issues before they lead to significant failures. -

Can the module detect misalignment in machinery?

Yes, it can detect misalignments by monitoring the position of rotating equipment, preventing wear and damage. -

Is the module compatible with other Bently Nevada systems?

Yes, the 3500/45-01-00 integrates seamlessly with other Bently Nevada 3500 series monitoring systems. -

What industries benefit from using the 3500/45-01-00?

The module is widely used in power generation, oil & gas, mining, manufacturing, and transportation industries. -

What mounting type does the module support?

The module is designed for rail mounting, making installation simple and efficient. -

Is the module CE and UL certified?

Yes, it is CE and UL certified, ensuring compliance with international safety and reliability standards.

Recommended Models (Same Series or Related Models)

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/45 | Position monitoring module | 241.3 × 24.4 × 99.1 mm | 0.2 kg |

| 3500/42M | Seismic monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/41 | Vibration monitoring module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/44 | Dynamic vibration monitor | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/46 | Expansion module for seismic monitoring | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

| 3500/47 | Temperature and vibration module | 241.3 × 24.4 × 163.1 mm | 0.46 kg |

Popular Bently Nevada Models

| Model | Description | Dimensions (L x W x H) | Weight |

|---|---|---|---|

| 3500/91-01-01-02 | Monitor module with advanced diagnostic features | 150 x 120 x 90 mm | 1.4 kg |

| 3500/91-01-01-BR | Vibration monitor module with Brazil certification | 150 x 120 x 90 mm | 1.3 kg |

| 3500/91-01-02-00 | Vibration monitor module with extended diagnostic capabilities | 150 x 120 x 90 mm | 1.5 kg |

| 3500/91-01-02-01 | Enhanced vibration monitor module with extended features | 150 x 120 x 90 mm | 1.5 kg |

| 3500/91-02-00-00 | Advanced version of vibration monitoring module | 150 x 120 x 90 mm | 1.6 kg |

| 3500/91-02-01-BR | Brazil-certified vibration monitoring module with advanced diagnostics | 150 x 120 x 90 mm | 1.6 kg |

Excellent PLC

Excellent PLC