| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

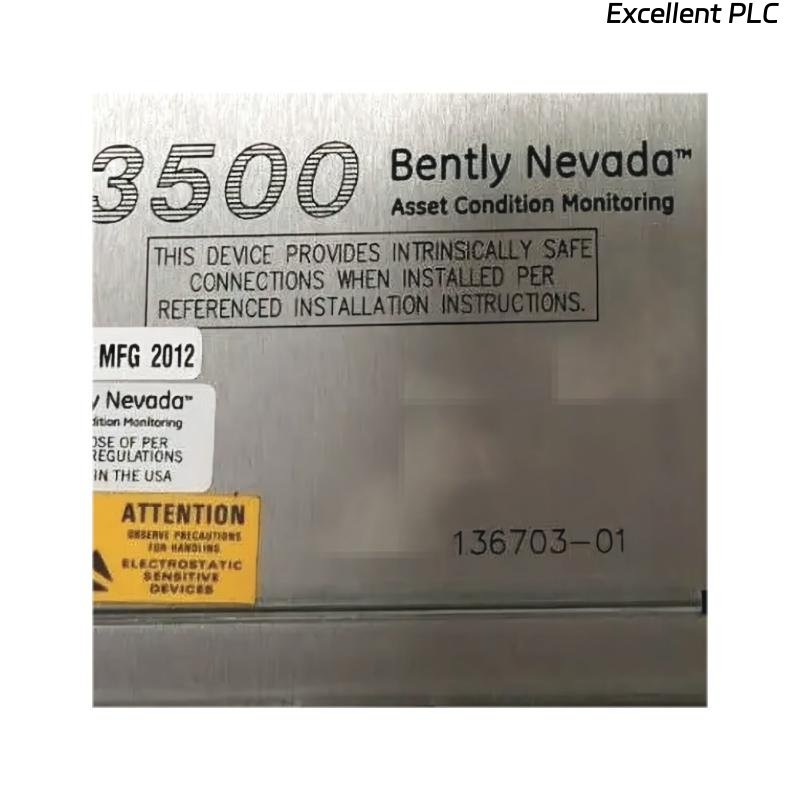

The 3500/50 Tachometer Module (Part Number 136703-01) is a dual-channel input module designed for the Bently Nevada 3500 Series machinery monitoring system. It accepts inputs from proximity probes or magnetic pickups to measure shaft rotational speed, rotor acceleration, and rotor direction. The module compares these measurements against user-programmable alarm setpoints and generates alarms when these setpoints are exceeded.

Key Features

-

Dual-channel input from proximity probes or magnetic pickups

-

Supports configurable functions: speed monitoring, setpoint alarming, speed band alarming, zero-speed notification, rotor acceleration alarming, and reverse rotation notification

-

Peak hold feature stores the highest speed, highest reverse speed, and number of reverse rotations

-

Supplies conditioned Keyphasor signals to the backplane of the 3500 rack, eliminating the need for a separate Keyphasor module

-

Configurable using the 3500 Rack Configuration Software

-

Front panel LEDs indicate module status, communication activity, and bypass status

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/50-04-00 (136703-01) |

| Channels | 2 |

| Input Signal Source | Proximity probes or magnetic pickups |

| Input Signal Range | +10 V to −24 V |

| Input Impedance | 20 kΩ (standard), 40 kΩ (TMR), or 7.15 kΩ (Internal Barrier) |

| Power Consumption | 5.8 W (typical) |

| Transducer Power Supply | 24 V DC, up to 40 mA per channel |

| Output Impedance | 550 Ω |

| RPM Range / Max Input Frequency | 0.0039 to 255 events/rev, up to 99,999 rpm, max 20 kHz |

| RPM Accuracy | <100 rpm: ±0.1 rpm; 100–10,000 rpm: ±1 rpm; above: ±0.01% |

| RPM/min Accuracy | ±20 rpm/min |

| Recorder Output | 4–20 mA proportional (short-circuit protected), update ~100 ms |

| Signal Resolution | 0.366 µA/bit, ±0.25% at 25°C, ±0.7% over temperature |

| Dimensions | 241.3 x 24.4 x 163.1 mm |

| Weight | 0.46 kg |

| Operating Temperature | −30°C to +65°C |

| Certifications | Standard 3500 series, TMR compatible |

Industry Applications

-

Shaft speed monitoring in turbines, compressors, pumps, and motors

-

Rotor acceleration and overspeed alert detection

-

Zero-speed detection and reverse rotation monitoring

-

Keyphasor signal generation for phase-referenced vibration analysis

-

Industrial process and condition monitoring in power generation, petrochemical, and rotating machinery automation

Product Advantages

-

Provides accurate and configurable speed-related diagnostics and alarming

-

Dual-channel processing and peak-hold features enhance fault detection

-

Internal termination reduces external complexity and wiring errors

-

Integrated Keyphasor output eliminates standalone timing modules

-

Rugged design suitable for harsh industrial environments

-

Compatible with TMR (Triple Modular Redundant) architectures for increased reliability

Frequently Asked Questions (FAQ)

-

How many transducer signals does it support?

Two channels—each can receive a signal from a proximity probe or magnetic pickup.

-

What input signal ranges and impedances are supported?

Accepts +10 V to −24 V; input impedance selectable as 20 kΩ, 40 kΩ (TMR), or 7.15 kΩ (barrier).

-

What is the maximum measurable shaft speed?

Up to 99,999 rpm; input frequency supported up to 20 kHz.

-

What accuracy can be expected?

Better than ±0.1 rpm under 100 rpm; ±1 rpm below 10,000 rpm; ±0.01% at higher speeds.

-

Does it support keyphasor output?

Yes—conditioned Keyphasor signals are output via the rack backplane.

-

What is the module’s power usage?

Typically ~5.8 W.

-

Is the module temperature rated for harsh conditions?

Yes—it operates from −30°C to +65°C.

-

Can it hold peak speed values?

Yes—it stores peak forward and reverse speeds and the count of reverse rotations.

-

What indicators does it feature?

Front LEDs for OK, TX/RX communications, and bypass status.

-

Does the package include internal wiring terminations?

Yes—this version includes internal termination for simplified installation.

Related Models

| Model Number | Description |

|---|---|

| 3500/50-01-00-01 (288062-02) | Tachometer Module with internal terminations |

| 3500/50-03-00 (133434-01) | Tachometer Module with external terminations |

| 3500/50-04-00 (136703-01) | TMR Tachometer I/O Module with internal terminations |

| 3500/70-01-00 (position module) | Position I/O Module |

| 3500/45-01-00 (135137-01) | Position I/O Module with internal termination |

| 3500/32-XX-00 Relay Module | Alarm Relay Output Module |

Popular Bently Nevada Modules

| Model Number | Description |

|---|---|

| 3500/22M (Rack Interface) | Rack Interface Module |

| 3500/55 | Overspeed Protection System |

| 3500/34-X Relay Module | 4-Channel Alarm Relay Module |

| 3500/70-01-00 | Position I/O Module |

| 3500/45-01-00 | Position I/O with Internal Termination |

| 3500/23-04-00 | Communication Gateway Module |

Excellent PLC

Excellent PLC