| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

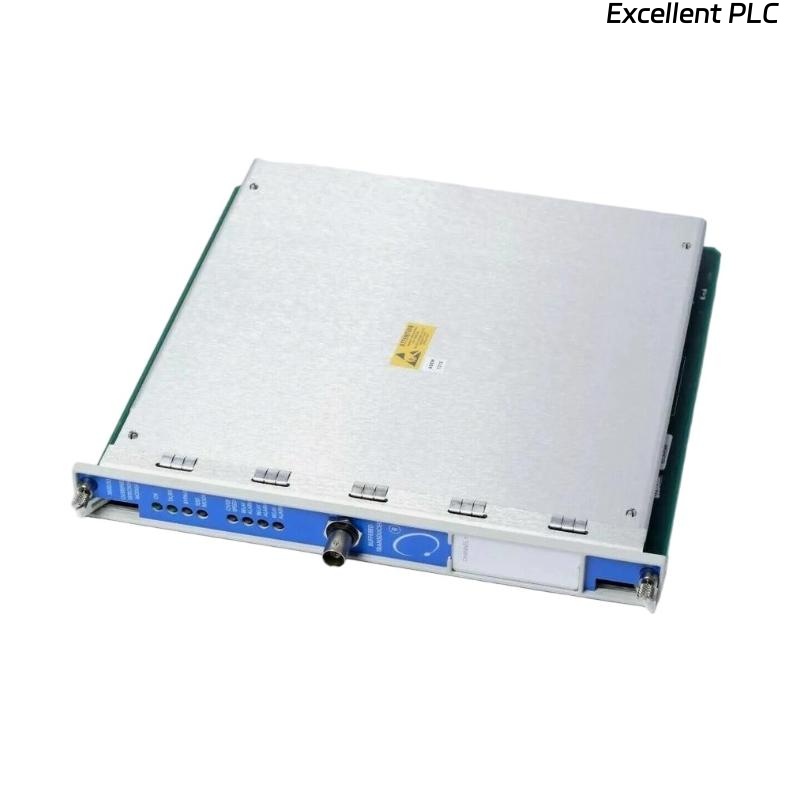

The Bently Nevada 3500/53 286566-01 Overspeed Detection Module is a critical component of the 3500 Machinery Protection System, designed to provide high-speed monitoring and protection for rotating machinery. It continuously monitors shaft speed via proximity probes or other sensors and triggers alarms or trips when the speed exceeds preconfigured limits. This module integrates seamlessly with other 3500 system components, ensuring safe and reliable operation of critical machinery.

Key Features

-

Accurate overspeed detection for critical machinery

-

Supports multiple sensor types (proximity probes, tachometers)

-

Configurable alarm and trip setpoints

-

Hot-swappable for minimal downtime

-

Rack-mounted for 3500 series systems

-

Real-time output compatible with System 1®

-

Rugged design suitable for harsh industrial environments

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3500/53 286566-01 |

| Module Type | Overspeed Detection Module |

| Manufacturer | Bently Nevada (Baker Hughes) |

| Function | Overspeed monitoring and machinery protection |

| Input Channels | 1 or 2 channels (proximity probe or sensor inputs) |

| Output Channels | Configurable alarm and trip outputs |

| Alarm/Trip Capability | Configurable per channel |

| Communication | Via 3500 rack backplane |

| Mounting Type | Rack-mounted (3500 series) |

| Power Supply | Supplied via 3500 rack |

| Operating Temperature | 0°C to 65°C |

| Storage Temperature | -40°C to 85°C |

| Humidity Range | 0% to 95% non-condensing |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Certifications | CE, CSA, ATEX, IECEx |

Industry Applications

-

Overspeed protection for turbines, compressors, and pumps

-

Rotating machinery monitoring in oil & gas, petrochemical, and refining plants

-

Power generation and heavy industrial facilities

-

Integration with System 1® for real-time condition monitoring

-

Machinery protection and predictive maintenance programs

Frequently Asked Questions (FAQ)

Q1: How many input channels does this module have?

It supports 1 or 2 sensor input channels.

Q2: Can it provide configurable alarm and trip outputs?

Yes, outputs are configurable per channel.

Q3: Is the module hot-swappable?

Yes, it can be replaced without shutting down the rack.

Q4: What types of sensors are supported?

Proximity probes, tachometers, or compatible speed sensors.

Q5: What is the operating temperature range?

0°C to 65°C.

Q6: Can it integrate with System 1®?

Yes, it provides real-time speed data compatible with System 1®.

Q7: What are the module’s dimensions and weight?

It measures 241.3mm x 24.4mm x 241.8 mm and weighs 0.82 kg.

Q8: Is it suitable for hazardous environments?

Yes, it meets CE, CSA, ATEX, and IECEx certifications.

Q9: Can it be used with all 3500 series racks?

Yes, it integrates seamlessly into 3500 series racks.

Q10: Can it detect overspeed in multiple machines?

Yes, it can monitor multiple shafts if properly configured within the system.

Related Models

| Model Number | Description |

|---|---|

| 3500/50 286566-02 | Tachometer Module |

| 3500/50 133442-01 | Tachometer Module (Earlier Version) |

| 3500/53 133819-01 | RTD/TC Temperature I/O Module |

| 3500/25M 149369-01 | Enhanced Keyphasor Module |

| 3500/32 125720-01 | 4-Channel Relay Module |

Popular Bently Nevada Modules

| Model Number | Description |

|---|---|

| 3500/05 | System Rack |

| 3500/15 | Power Supply Module |

| 3500/20 | Data Manager I/O Module |

| 3500/25 | Keyphasor Module |

| 3500/32 | Relay Module |

| 3500/40M | Proximitor Monitor |

Excellent PLC

Excellent PLC