| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

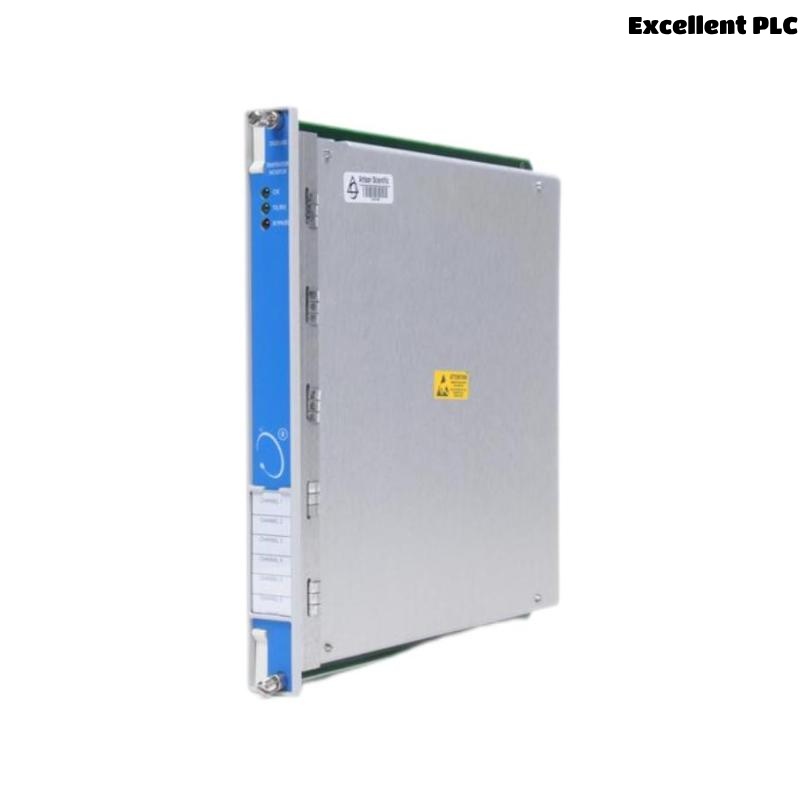

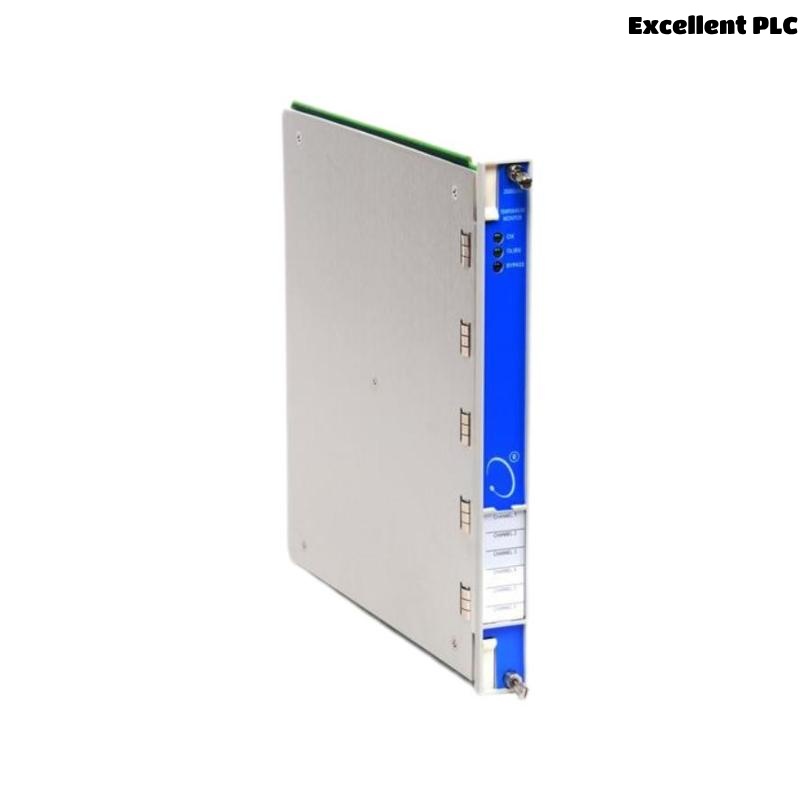

The Bently Nevada 3500/60-01-00 (133811-01) Temperature Monitor is a critical component of the Bently Nevada 3500 Machinery Protection System, specifically designed for continuous temperature monitoring of industrial machinery. This six-channel module accepts inputs from thermocouples (TCs) or Resistance Temperature Detectors (RTDs) and provides precise conditioning, measurement, and alarm functionality. It is essential for protecting rotating equipment by monitoring temperature variations that indicate potential faults, improving plant safety and system reliability.

Key Features

-

Six independent temperature input channels

-

Supports both RTD and Thermocouple (TC) sensor types

-

Compatible with RTD types: Platinum, Nickel, Copper

-

Supports thermocouple types: E, J, K, T

-

Integrated programmable Alert and Danger alarm thresholds

-

High measurement accuracy and fast response times

-

Channel-to-channel isolation available with Isolated I/O modules

-

Visual status indicators: OK, TX/RX, and Bypass LEDs on the front panel

-

Compatible with Triple Modular Redundancy (TMR) configurations for maximum reliability

-

Designed for harsh industrial environments with global certifications

Technical Specifications

| Parameter | Specification |

|---|---|

| Module Type | Six-Channel Temperature Monitor |

| Supported Sensor Types | RTD: Platinum, Nickel, Copper; TC: E, J, K, T |

| Number of Channels | 6 independent channels |

| RTD Source Current | 925 μA ±15 μA per channel |

| Input Impedance | >10 MΩ per lead |

| Alarm Thresholds | Programmable Alert and Danger levels with time delays |

| Channel Isolation | 250 Vrms channel-to-channel (with Isolated I/O) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 0% to 95% RH, non-condensing |

| Certifications | ATEX, IECEx, UL, CSA, RoHS, EMC compliant |

| System Compatibility | Fully compatible with Bently Nevada 3500 Series |

Typical Applications

-

Bearing temperature monitoring in turbines, compressors, and pumps

-

Motor winding and stator temperature monitoring

-

Machinery protection in power generation, petrochemical, and manufacturing industries

-

Integration with plant-wide safety systems for shutdown or alarm activation

-

Condition monitoring to enable predictive maintenance strategies

-

Triple Modular Redundancy (TMR) system configurations for critical assets

Product Advantages

-

Versatile support for both RTD and Thermocouple sensors in one module

-

High-density six-channel design reduces system footprint

-

Advanced alarm logic provides early detection of abnormal conditions

-

Integrated isolation (with Isolated I/O) enhances measurement accuracy and system safety

-

LED indicators allow quick visual assessment of module status

-

Compatible with hazardous area requirements via global certifications

-

Robust construction for long-term reliable operation in harsh environments

-

Seamless integration into the Bently Nevada 3500 rack-based monitoring system

-

Supports mission-critical rotating equipment protection applications

-

Reduces downtime by enabling proactive maintenance responses

Frequently Asked Questions (FAQ)

-

What types of sensors can the 3500/60-01-00 module accept?

It supports RTD sensors (Platinum, Nickel, Copper) and Thermocouples (E, J, K, T types). -

How many temperature channels are available?

The module offers six independent input channels. -

Does this module support isolated inputs?

Yes, with Isolated I/O modules, providing 250 Vrms channel-to-channel isolation. -

Can the alarm levels be programmed?

Yes, both Alert and Danger alarm thresholds are fully programmable with configurable delays. -

What is the typical RTD source current?

Approximately 925 μA per channel. -

Is this module compatible with TMR systems?

Yes, it is designed for use in Triple Modular Redundancy (TMR) configurations for enhanced reliability. -

What industries typically use this module?

Power generation, oil and gas, petrochemical, manufacturing, and other industries requiring reliable temperature monitoring. -

Are front-panel indicators available?

Yes, LEDs indicate OK, TX/RX communication, and Bypass status. -

What are the operating conditions for the module?

It operates from -30°C to +65°C with up to 95% RH non-condensing humidity. -

Is this module compliant with global standards?

Yes, it carries ATEX, IECEx, UL, CSA, RoHS, and EMC certifications.

Recommended Related Models

| Model | Description |

|---|---|

| Bently Nevada 3500/61 | Six-Channel Temperature Monitor with Recorder Outputs |

| Bently Nevada 3500/34 | 16-Channel Digital Input Module |

| Bently Nevada 3500/36 | Thermocouple Input Module |

| Bently Nevada 3500/25 | Enhanced Keyphasor Module |

| Bently Nevada 3500/55 | Dual-Channel Velocity Sensor Module |

| Bently Nevada 3500/32 | 8-Channel Relay Output Module |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| Bently Nevada 3300 XL | Proximity and Vibration Monitoring System |

| Bently Nevada 3500/40 | Velocity Sensor Module |

| Bently Nevada 3500/46 | Temperature Sensor Module |

| Bently Nevada 3500/60 | Six-Channel Temperature Monitor (Standard Version) |

| Bently Nevada 3500/61 | Six-Channel Temperature Monitor with Recorder Outputs |

| Bently Nevada 7200 | Wireless Vibration Monitoring System |

Excellent PLC

Excellent PLC