| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

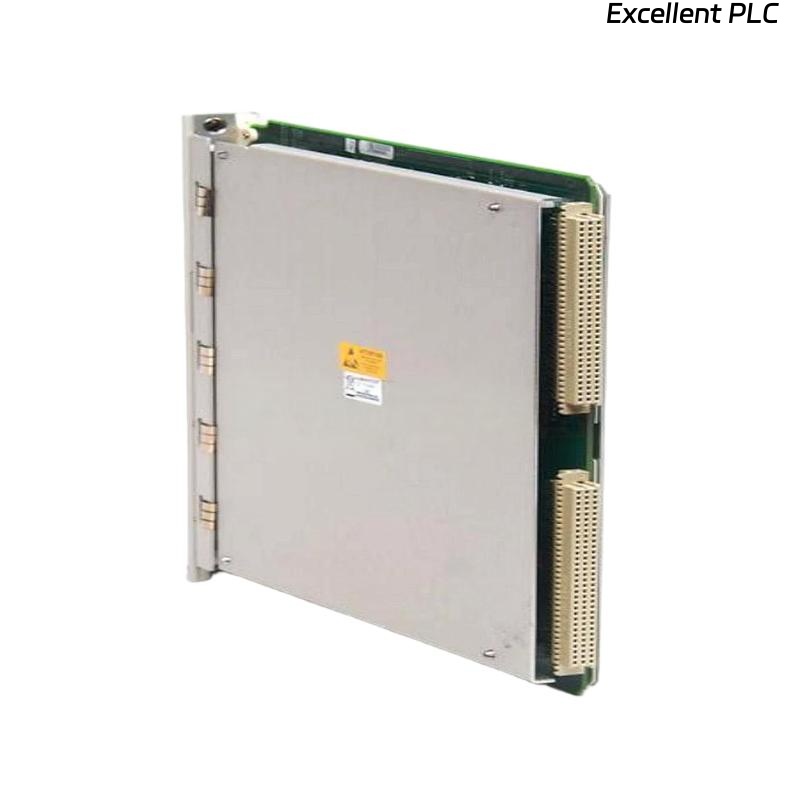

The Bently Nevada 3500/62 163179-03 Process Variable Monitor is an advanced industrial monitoring solution that is engineered to continuously measure and monitor critical process variables. This device is part of the renowned Bently Nevada 3500 series, a series of products trusted for their accuracy, durability, and high performance in demanding industrial environments.

The 3500/62 monitor is capable of handling a wide range of industrial sensors and is designed to deliver real-time data analysis for process variables such as vibration, temperature, pressure, flow, and more. This capability makes it an essential tool for predictive maintenance, fault detection, and process optimization across industries such as power generation, oil and gas, petrochemical, and manufacturing.

The module supports both digital and analog outputs, allowing it to be easily integrated into existing industrial automation systems. Its high accuracy, combined with its robust design, ensures that operators can rely on this device to monitor critical parameters in real-time, preventing costly equipment downtime and failures.

Product Specifications

| Specification | Details |

|---|---|

| Model Number | 3500/62 163179-03 |

| Type | Process Variable Monitor |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Power Consumption | 3.0 W (max) |

| Input/Output Channels | 8 Analog Inputs/Outputs |

| Operating Temperature | -40°C to +85°C |

| Input Range | 0-10 V DC, 4-20 mA |

| Output Type | Digital and Analog |

| Signal Processing | Filtering, Scaling, Calibration |

| Isolation Voltage | 2500 V AC |

| Mounting | Rack-mounted |

| Environmental Protection | IP20 (Indoor use) |

| Certification | UL, CE, RoHS |

Product Application

The Bently Nevada 3500/62 163179-03 is designed for industrial process monitoring in critical systems that require continuous, real-time analysis of key variables. Its application spans across various industries where maintaining the health of machinery and process systems is essential. Key applications include:

-

Vibration Monitoring: The 3500/62 continuously tracks the vibration levels of rotating machinery like motors, pumps, and turbines. It helps identify issues such as imbalance, misalignment, and bearing wear before they result in costly failures.

-

Temperature Monitoring: The module is capable of monitoring temperatures in key equipment such as compressors and reactors, ensuring that systems stay within safe operational ranges and preventing overheating.

-

Pressure Monitoring: It tracks system pressures in pipelines and tanks, ensuring that pressure levels remain within safe operating limits and preventing system failures due to overpressure or pressure drops.

-

Flow Monitoring: By monitoring flow rates of fluids or gases, the 3500/62 helps optimize processes by ensuring that systems are running efficiently and identifying anomalies early.

-

Pump and Motor Protection: It helps prevent damage to critical components like pumps and motors by continuously monitoring key parameters that could indicate wear or malfunction.

These applications are crucial in industries such as power generation, oil and gas, chemical processing, and mining, where even minor failures can lead to major safety, performance, and financial issues.

Product Advantages

-

Multi-Channel Monitoring: With 8 input/output channels, the 3500/62 can monitor multiple process variables simultaneously, making it ideal for complex industrial environments with a need for comprehensive monitoring.

-

Real-Time, High-Accuracy Data: The device provides precise, real-time data on critical parameters, enabling immediate action to be taken to mitigate risks or improve system performance.

-

Wide Temperature Range: The module operates effectively in a wide temperature range from -40°C to +85°C, ensuring it is suitable for both hot and cold environments, typical of many industrial settings.

-

Seamless Integration: Designed to be compatible with other products in the Bently Nevada 3500 series, this module integrates smoothly into a unified monitoring system.

-

Energy Efficient: Consuming only a maximum of 3.0 W of power, the 3500/62 minimizes energy usage, contributing to reduced operational costs over time.

-

Electrical Isolation for Protection: The device provides 2500 V AC isolation between input and output channels, offering superior protection against electrical surges and ensuring the longevity of both the module and other connected devices.

-

Compact Design: With dimensions of 241.3 x 24.4 x 241.8 mm and a lightweight design (0.82 kg), the module fits easily into space-constrained environments while maintaining high performance.

-

Certifications for Safety: The module is UL, CE, and RoHS certified, meeting international standards for safety and environmental impact.

Frequently Asked Questions (FAQ)

-

What type of input/output channels does the Bently Nevada 3500/62 support?

-

The module supports 8 analog input/output channels for continuous real-time monitoring of multiple process variables.

-

-

What is the maximum input voltage the module can handle?

-

The module supports a maximum input voltage of 10 V DC and a current input range of 4-20 mA.

-

-

Can the 3500/62 module be used in hazardous areas?

-

The module is designed for industrial applications but may require additional certifications for use in hazardous locations. Please consult with your installation requirements.

-

-

How does the module handle electrical protection?

-

The 3500/62 provides 2500 V AC isolation between input and output channels, ensuring protection from electrical surges and interference.

-

-

What is the power consumption of the Bently Nevada 3500/62?

-

The maximum power consumption is 3.0 W.

-

-

How does the Bently Nevada 3500/62 monitor process variables?

-

The module processes both analog and digital signals, providing real-time data for accurate monitoring of critical variables like temperature, pressure, vibration, and flow.

-

-

Is the Bently Nevada 3500/62 compatible with other Bently Nevada products?

-

Yes, the 3500/62 is fully compatible with other modules from the Bently Nevada 3500 series, providing an integrated solution for monitoring and control.

-

-

What certifications does the 3500/62 hold?

-

The module is certified by UL, CE, and RoHS, ensuring it complies with global safety and environmental standards.

-

-

What is the size and weight of the 3500/62 module?

-

The module has dimensions of 241.3 x 24.4 x 241.8 mm and weighs 0.82 kg.

-

-

Can the module handle both analog and digital signals?

-

Yes, the 3500/62 can handle both analog and digital signals, allowing for flexibility in monitoring various process parameters.

-

Recommended Models from the Bently Nevada 3500 Series

| Model Number | Description |

|---|---|

| 3500/33 | Vibration Monitoring Module |

| 3500/20 | Speed Monitoring Module |

| 3500/42 | Tachometer Module |

| 3500/61 | 4-20 mA Input/Output Module |

| 3500/94 | Relay Output Module |

| 3500/22 | Dynamic Pressure Module |

Other Popular Models from Bently Nevada

| Model Number | Description |

|---|---|

| 9200-01-02-10-00 | Standard Monitoring Module |

| 9200-01-02-10-01 | Enhanced Monitoring Unit |

| 9200-01-02-10-02 | High-Sensitivity Monitoring Module |

| 9200-01-02-11-04 | Multi-Channel Monitoring Unit |

| 9200-01-02-11-05 | Compact Monitoring System |

| 9200-01-02-11-06 | Precision Monitoring System |

Excellent PLC

Excellent PLC