| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

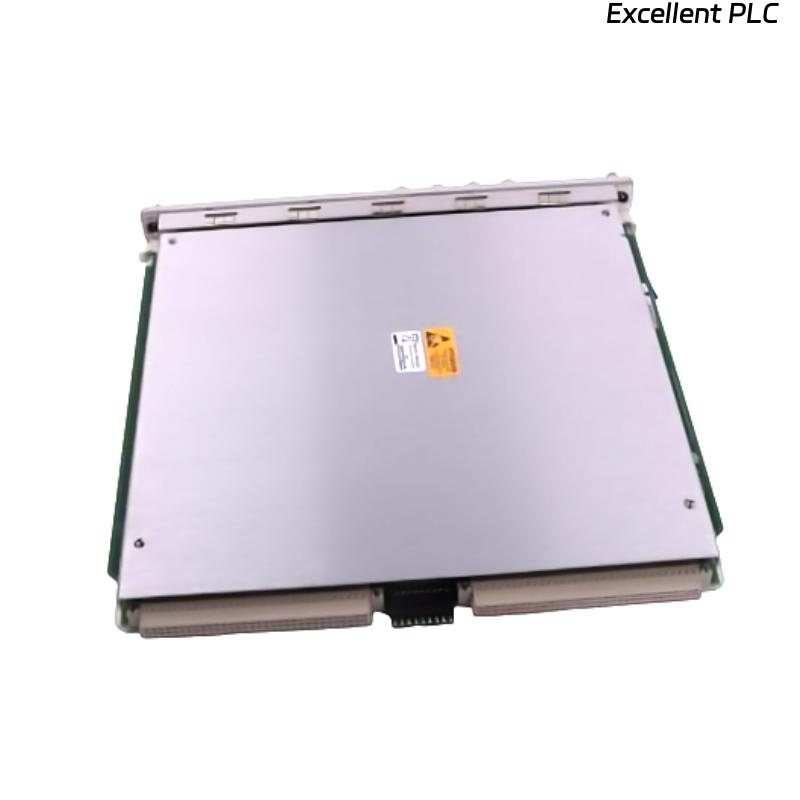

The Bently Nevada 3500/64 Dynamic Pressure Module (part number 176449-05) is an advanced signal processing module designed to monitor dynamic pressure signals in rotating machinery applications. Installed in the trusted 3500 machinery protection platform, this module provides continuous, high-resolution analysis of pressure fluctuations that may indicate combustion instability, surge, pulsation, or other operational anomalies. It is optimized for use with dynamic pressure transducers and is ideal for machinery such as gas turbines and reciprocating compressors where pressure behavior plays a critical role in performance and safety.

As part of Bently Nevada’s comprehensive vibration and condition monitoring ecosystem, the 3500/64 expands traditional monitoring to include a powerful tool for capturing pressure phenomena that would otherwise go unnoticed, enabling predictive diagnostics and process optimization.

Product Specifications

| Parameter | Value |

|---|---|

| Module Type | Dynamic Pressure Monitor Module |

| Part Number | 176449-05 |

| Input Channels | 4 dynamic pressure signal channels |

| Input Type | AC-coupled voltage signal from dynamic pressure transducers |

| Input Range | ±20 V |

| Frequency Response | 1 Hz to 20 kHz (configurable filter ranges) |

| Signal Processing | RMS, Peak, Peak-to-Peak, FFT analysis |

| Transducer Power | Constant current excitation (if required) |

| Buffered Outputs | Yes, one per channel |

| Alarm Setpoints | 2 per channel (Alert and Danger) |

| Compatible Sensors | Dynamic pressure sensors (e.g., Bently Nevada 165855) |

| Communication Interface | Internal rack backplane (via 3500/22M System Monitor) |

| System Integration | Compatible with 3500 rack-mounted modules and online systems |

| Operating Temperature | -30°C to +65°C |

| Relative Humidity | 95% non-condensing |

| Certifications | CE, ATEX, IECEx, CSA (when installed in a compliant system) |

| Mounting | 3500 rack (1 slot + 1 I/O module slot) |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

Product Applications

The 3500/64 Dynamic Pressure Module is widely used across a range of industries and critical equipment where pressure fluctuations are indicative of machine health or process stability:

-

Gas Turbines

For detecting combustion dynamics, pressure pulsations, and surge conditions. -

Reciprocating Compressors

To monitor cylinder pressure dynamics and valve behavior. -

Centrifugal Compressors

For surge detection and aerodynamic instability tracking. -

Pipelines and Process Systems

Monitoring pressure resonance, fluid hammer, or pressure oscillations. -

Aero-derivative Engines

Identifying combustion instabilities that may lead to structural damage.

The module enables advanced diagnostics that go beyond traditional vibration monitoring, giving engineers early warning signals for complex, transient pressure anomalies.

Product Advantages

The Bently Nevada 3500/64 offers numerous functional and operational advantages:

-

Expanded Monitoring Capability

Enables monitoring of dynamic pressure events, complementing vibration and temperature modules. -

High-Frequency Response

Captures fast transients and pressure instabilities not detectable with standard sensors. -

Customizable Signal Processing

Provides RMS, Peak, and FFT outputs configurable per application need. -

Flexible Sensor Compatibility

Supports a wide range of dynamic pressure transducers, including piezoelectric types. -

Integrated Alarm Management

Dual-level alarms (Alert and Danger) allow for graded response strategies. -

System Integration

Fully compatible with the 3500 platform, allowing seamless addition into existing protection systems. -

Real-Time Analysis

Facilitates live diagnostics through buffered outputs and integration with the 3500/93 display or 3500/22M system monitor.

Frequently Asked Questions (FAQ)

-

Can the 3500/64 module perform FFT analysis on pressure signals?

Yes, FFT output is available for spectral analysis of dynamic pressure data. -

What signal conditioning features are available on the module?

Bandpass filtering, RMS, Peak, and Peak-to-Peak computations can be configured per channel. -

Is buffered output available for each input channel?

Yes, each channel includes a buffered output for connection to portable analyzers. -

Does this module support constant current sensor excitation?

Yes, the module can power sensors that require IEPE excitation. -

What types of pressure transducers are compatible with the 3500/64?

It supports piezoelectric dynamic pressure sensors with voltage outputs, such as the Bently 165855. -

Can I set individual alarm levels for each channel?

Yes, both Alert and Danger levels are individually configurable per channel. -

Is it possible to record transient events using this module?

Yes, the high-frequency response and real-time output allow for capture of transient pressure spikes. -

How does the module communicate with other 3500 components?

All data communication is handled via the backplane to the System Monitor (3500/22M). -

Is the module suitable for SIL-certified applications?

While not a safety module on its own, it can be used in SIL-rated systems if configured appropriately. -

Can the module be remotely configured?

Yes, configuration is performed using the 3500 Configuration Software through the System Monitor interface.

Related Models from the Same Series

| Model | Description |

|---|---|

| 3500/61 145988-02 | Temperature Monitor Module |

| 3500/65 145988-01 | Velocity Monitor Module |

| 3500/60 164470-01 | Temperature RTD Monitor |

| 3500/70M 176449-09 | Recip Rod Position Monitor |

| 3500/77M 149986-01 | TSI Module (Turbine Supervisory Instrumentation) |

| 3500/73 145701-01 | Air Gap Monitor Module |

Popular Models from the Same Brand

| Model | Description |

|---|---|

| 3500/42M 176449-02 | Proximitor Seismic Monitor |

| 3500/22M 288055-01 | System Interface Module |

| 3500/93 135799-01 | Display Interface Module |

| 3300 XL 330103-00-05 | Proximity Probe |

| 3500/50M 286566-01 | Tachometer Module |

| 3500/15E 133292-01 | Power Supply Module |

Excellent PLC

Excellent PLC