| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

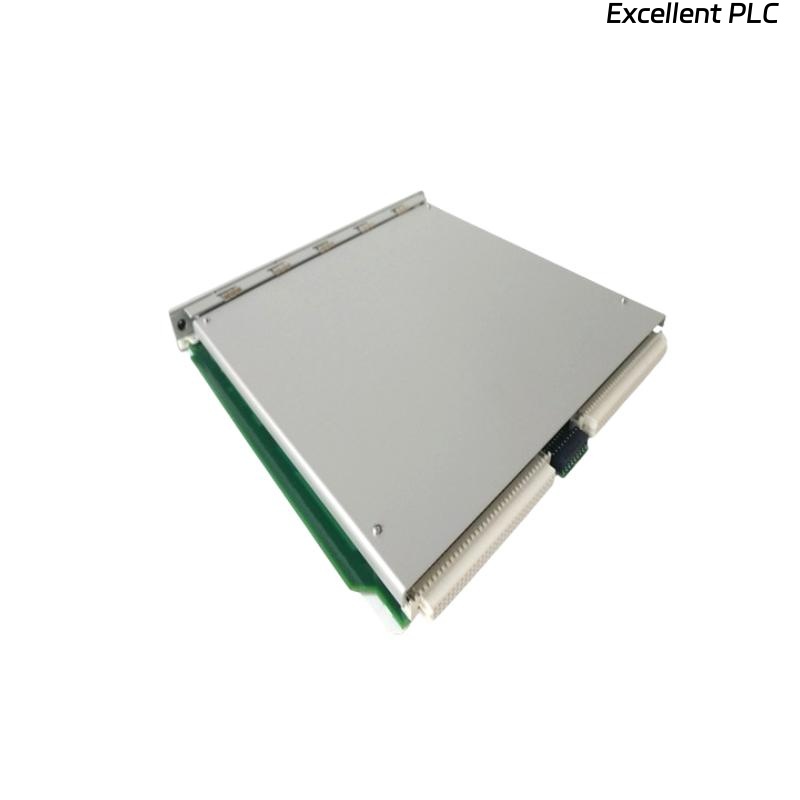

The Bently Nevada 3500/64M 176449-05 + 140471-02 Dynamic Pressure Monitor is an integrated solution for dynamic pressure monitoring in industrial systems. This system combines two critical modules—the 3500/64M Dynamic Pressure Monitor and the 3500/64M I/O Module with Internal Termination—to provide a robust, real-time monitoring system that can detect even minor changes in dynamic pressure, ensuring the smooth operation of industrial machinery.

With its high sensitivity, the 3500/64M is designed for the continuous monitoring of dynamic pressure in critical systems such as turbines, compressors, pumps, reactors, and pipelines. It provides operators with timely alerts when pressure changes exceed predefined thresholds, allowing for quick interventions that minimize downtime and reduce maintenance costs.

This dual-module solution is used widely in industries such as power generation, oil and gas, chemical processing, and mining, where machinery must operate at peak performance and safety levels to avoid system failures and costly downtime.

Product Specifications

| Specification | Details |

|---|---|

| Model Numbers | 3500/64M 176449-05 + 140471-02 |

| Type | Dynamic Pressure Monitor + I/O Module |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.82 kg |

| Power Consumption | 4.5 W (max) |

| Input Channels | 8 Analog Inputs |

| Output Channels | Analog and Digital Outputs |

| Operating Temperature | -40°C to +85°C |

| Input Voltage Range | 0-10 V DC, 4-20 mA |

| Signal Processing | Real-time Filtering, Alarm Generation |

| Isolation Voltage | 2500 V AC |

| Mounting | Rack-mounted |

| Environmental Protection | IP20 (Indoor use) |

| Certification | UL, CE, RoHS |

Product Application

The Bently Nevada 3500/64M 176449-05 + 140471-02 Dynamic Pressure Monitor is specifically designed to monitor dynamic pressure across various industrial processes, ensuring optimal operation and preventing potential failures. Its applications are diverse and critical in various industries:

-

Power Generation: In power plants, dynamic pressure monitoring is essential for detecting early signs of turbine imbalances, misalignments, or potential failures. This monitor ensures that pressure fluctuations in turbines and related systems are captured in real time, enabling preventative maintenance.

-

Oil and Gas: Dynamic pressure data is critical in the oil and gas sector for monitoring the operation of compressors, pipelines, and blowout preventers. The 3500/64M can detect pressure changes caused by operational issues, pipeline blockages, or equipment malfunction, allowing operators to address issues before they escalate.

-

Chemical Processing: In chemical manufacturing, accurate pressure control is necessary for the safe and efficient operation of reactors, pumps, and other critical equipment. This monitor ensures that process pressure remains within optimal ranges, preventing overpressure conditions that could result in hazardous situations.

-

Mining: The 3500/64M plays a key role in underground and surface mining operations, where pressure fluctuations in pneumatic systems and hydraulic machinery need to be detected and managed in real time to ensure worker safety and equipment performance.

-

Industrial Manufacturing: Dynamic pressure monitoring is also vital for large-scale manufacturing processes involving hydraulic systems, pneumatic equipment, and fluid power systems. The 3500/64M ensures that all dynamic pressure changes are detected early, preventing costly equipment failures.

In all these industries, the system’s ability to monitor dynamic pressure in real-time allows for the early detection of performance issues, reducing unplanned downtime, extending equipment life, and improving overall system reliability.

Product Advantages

-

Comprehensive Monitoring: Combining dynamic pressure monitoring with an I/O module for seamless data integration, the 3500/64M allows for comprehensive monitoring of industrial processes from a single platform.

-

High Sensitivity: The module’s high sensitivity ensures that even minor fluctuations in dynamic pressure are detected. This capability is crucial for identifying potential failures at an early stage.

-

Real-Time Alarm Generation: The 3500/64M features advanced alarm functionality that instantly alerts operators when pressure conditions deviate from the predefined safe thresholds, enabling quick responses to prevent damage or operational downtime.

-

Versatile Applications: This monitor can be used across a wide range of industries and applications, including oil and gas, chemical, power generation, and mining, making it a versatile solution for dynamic pressure monitoring needs.

-

Durable and Reliable: With 2500 V AC isolation between input/output channels, the 3500/64M is protected against electrical surges, ensuring stable performance in harsh industrial environments. Its rugged construction ensures that it operates reliably over time.

-

Energy Efficient: Consuming just 4.5 W of power, the module is highly energy-efficient, which reduces operating costs without compromising on performance.

-

Flexible Integration: The 3500/64M can integrate with other Bently Nevada products, offering a complete monitoring and control solution for complex industrial systems.

-

Certified Safety: The 3500/64M meets high standards of safety and quality, with certifications such as UL, CE, and RoHS, ensuring that the system adheres to international safety and environmental regulations.

-

Compact Design: Despite offering comprehensive monitoring capabilities, the system’s compact size (241.3 x 24.4 x 241.8 mm) makes it easy to install in confined spaces, saving valuable installation space.

Frequently Asked Questions (FAQ)

-

What types of applications can the Bently Nevada 3500/64M monitor?

-

The 3500/64M is ideal for applications in power generation, oil and gas, chemical processing, mining, and industrial manufacturing, where dynamic pressure monitoring is essential.

-

-

How does the Bently Nevada 3500/64M handle alarms?

-

The 3500/64M is equipped with advanced alarm generation features, notifying operators immediately when pressure deviates from safe limits.

-

-

What is the size and weight of the Bently Nevada 3500/64M?

-

The module has dimensions of 241.3 x 24.4 x 241.8 mm and weighs 0.82 kg.

-

-

Can the Bently Nevada 3500/64M interface with other monitoring systems?

-

Yes, it can integrate seamlessly with other Bently Nevada products, creating a unified industrial monitoring solution.

-

-

What is the maximum power consumption of the Bently Nevada 3500/64M?

-

The maximum power consumption is 4.5 W.

-

-

What is the temperature range for operating the Bently Nevada 3500/64M?

-

The module operates within a temperature range of -40°C to +85°C.

-

-

Is the Bently Nevada 3500/64M suitable for hazardous environments?

-

Yes, the 3500/64M is designed to meet high standards of safety and durability, including certifications like UL, CE, and RoHS, making it suitable for hazardous industrial environments.

-

-

How does the Bently Nevada 3500/64M help prevent equipment failure?

-

By detecting abnormal pressure fluctuations early, the 3500/64M allows operators to perform preventative maintenance, reducing the risk of equipment failure and extending the life of machinery.

-

-

What types of sensors are compatible with the Bently Nevada 3500/64M?

-

The 3500/64M is compatible with a wide range of dynamic pressure sensors used in various industrial applications.

-

-

Can the Bently Nevada 3500/64M be used in a rack-mounted configuration?

-

Yes, the module is designed for rack-mounting, allowing for easy installation in control systems.

-

Recommended Models from the Bently Nevada 3500 Series

| Model Number | Description |

|---|---|

| 3500/33 | Vibration Monitoring Module |

| 3500/20 | Speed Monitoring Module |

| 3500/42 | Tachometer Module |

| 3500/61 | 4-20 mA Input/Output Module |

| 3500/94 | Relay Output Module |

| 3500/22 | Dynamic Pressure Module |

Other Popular Models from Bently Nevada

| Model Number | Description |

|---|---|

| 330103-00-09-10-02 | Standard Vibration Monitoring Module |

| 330103-00-09-10-03 | Advanced Vibration Monitoring Unit |

| 330103-00-09-10-04 | High-Sensitivity Vibration Detection |

| 330171-00-16-10-02-00 | Compact Vibration Monitoring Unit |

| 330171-00-16-10-02-01 | Multi-Channel Vibration Monitoring |

| 330171-00-16-10-02-02 | Precision Vibration Monitoring System |

Excellent PLC

Excellent PLC