| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

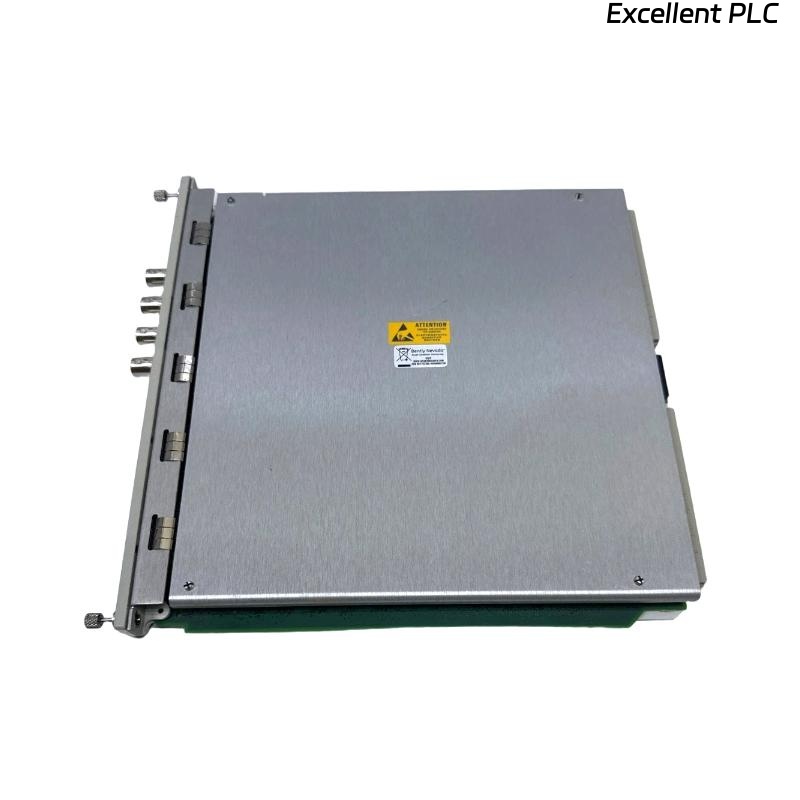

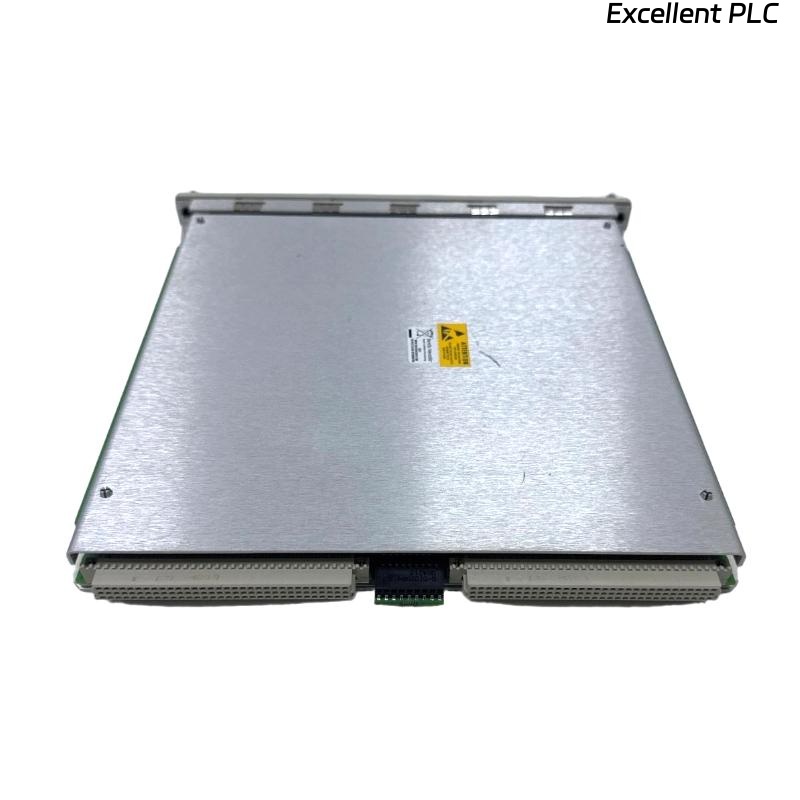

The Bently Nevada 3500/72 140734-08 Recip Rod Position Monitor is a specialized monitoring module designed to provide accurate measurements of rod motion in reciprocating machinery. Part of the 3500 Series Machinery Protection System, it delivers critical information for machinery protection, process optimization, and predictive maintenance.

This monitor measures the displacement of reciprocating rods in compressors and pumps, providing operators with real-time position data. By accurately tracking rod position, the 3500/72 module helps prevent mechanical overtravel, detect misalignment, and monitor overall machine health. Integration with other 3500 Series modules allows for centralized monitoring, alarm management, and system diagnostics.

Product Specifications

| Parameter | Description |

|---|---|

| Model | Bently Nevada 3500/72 140734-08 |

| Product Type | Recip Rod Position Monitor |

| Input Type | Proximity probe or displacement sensor |

| Number of Channels | 1-channel standard (expandable with multiple modules) |

| Measurement Range | ±50 mm (typical; configurable per sensor) |

| Frequency Response | DC to 1 kHz |

| Alarm Capability | Rod overtravel, high/low limits, windowed alarms |

| Signal Isolation | Full galvanic isolation for input and output circuits |

| Accuracy | ±0.25% of full scale |

| Response Time | <20 ms |

| Communication | 3500 Series backplane interface |

| Power Supply | 24 VDC nominal |

| Operating Temperature | 0 to 60 °C |

| Storage Temperature | -20 to 70 °C |

| Relative Humidity | 5% to 95% non-condensing |

| Compliance | CE, UL, CSA |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

Product Applications

The 3500/72 Recip Rod Position Monitor is widely used in industrial applications where reciprocating machinery performance and safety are critical:

-

Oil & Gas – Monitoring reciprocating compressors for pipeline and refinery operations.

-

Petrochemical – Tracking rod positions in reciprocating pumps and process compressors.

-

Power Generation – Ensuring safe rod travel in reciprocating auxiliary pumps and compressors.

-

Chemical Processing – Detection of abnormal rod motion in critical process equipment.

-

Marine & Offshore – Real-time rod position monitoring on shipboard compressors and pumps.

-

Industrial Manufacturing – Preventing overtravel and mechanical damage in reciprocating machinery.

Product Advantages

-

High Precision Measurement – ±0.25% full-scale accuracy ensures reliable rod position monitoring.

-

Fast Response – <20 ms response time allows for quick detection of abnormal motion.

-

Wide Frequency Range – DC to 1 kHz captures slow and fast rod movements.

-

Full Signal Isolation – Protects system from electrical noise and ensures measurement integrity.

-

Flexible Alarm Options – Configurable overtravel, high/low limits, and windowed alarms for customized protection.

-

Seamless Integration – Fully compatible with Bently Nevada 3500 Series systems for centralized monitoring and diagnostics.

-

Robust Industrial Design – Built to withstand electrically noisy and harsh operating environments.

-

Diagnostic Feedback – Channel status and fault indication for enhanced system reliability.

FAQ

-

What type of sensors does the 3500/72 support?

Proximity probes or displacement sensors are supported. -

How many channels are available per module?

Each module provides 1 channel; multiple modules can be installed for additional monitoring points. -

What is the measurement range?

±50 mm typical, configurable based on the sensor and installation. -

What is the module’s frequency response?

DC to 1 kHz. -

Can it trigger alarms for rod overtravel?

Yes, configurable overtravel and windowed alarms are supported. -

Is the input signal isolated from other channels and the backplane?

Yes, full galvanic isolation is provided. -

What is the response time of the module?

Less than 20 ms. -

How accurate is the rod position measurement?

±0.25% of full-scale reading. -

Does it integrate with the 3500 Series backplane system?

Yes, it communicates and integrates seamlessly with other 3500 Series modules. -

Can it operate reliably in electrically noisy industrial environments?

Yes, it is designed for harsh industrial conditions and maintains signal integrity.

Recommended Related Models (Same Series or Family)

| Model | Description |

|---|---|

| 3500/72 140734-07 | Recip Rod Position Monitor, previous variant |

| 3500/72 140735-01 | Dual-channel Recip Rod Position Monitor |

| 3500/70 176449-09 | Recip Impulse Velocity Monitor |

| 3500/65 184469-01 | 16-Channel Temperature Monitor |

| 3500/62 133811-03 | Process Variable Monitor |

| 3500/60 136711-01 | I/O Module with Internal Barriers |

Popular Bently Nevada Models (Same Brand)

| Model | Description |

|---|---|

| 3500/50 132608-01 | Proximity Probe Monitor |

| 3500/20 134210-01 | Vibration Transducer Module |

| 3500/65 145988-02 | 16-Channel Temperature Monitor |

| 3500/62 136483-01 | Isolated I/O Module |

| 330130-040-00 | 3300 XL Vibration Sensor |

| 3500/60 136711-01 | I/O Module with Internal Barriers |

Excellent PLC

Excellent PLC