| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

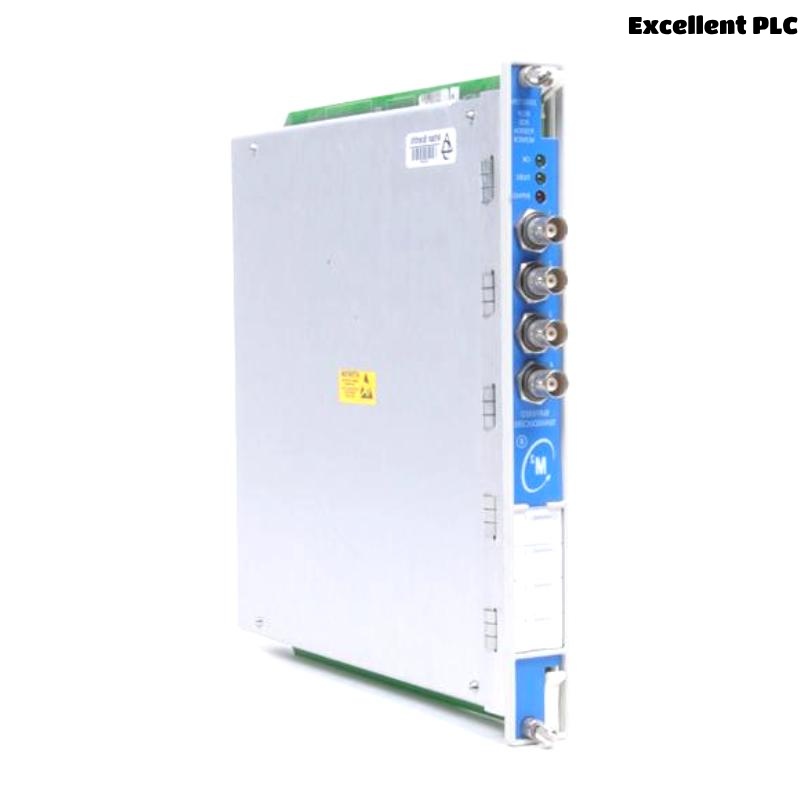

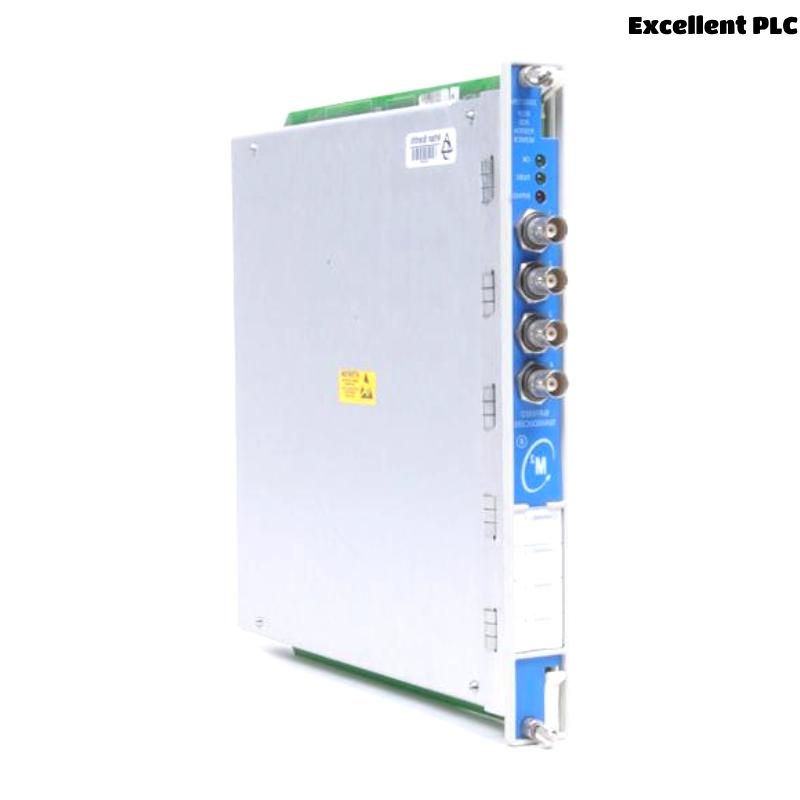

Product Introduction

The Bently Nevada 3500/72M 176449-08 is a highly specialized Recip Rod Position Monitor designed to measure both rod drop and rod position in reciprocating compressors. As part of the Bently Nevada 3500 Machinery Protection System, this module plays a vital role in monitoring the condition of internal reciprocating compressor components, such as piston rods, crossheads, and cylinders, to detect mechanical wear or misalignment before catastrophic failure occurs.

Equipped with dual-channel inputs, the 3500/72M captures dynamic changes in rod movement using proximity probes. It integrates directly into the 3500 rack, providing continuous online surveillance and supporting automated alarms and shutdowns in response to abnormal equipment behavior. This version (176449-08) features enhanced firmware, higher resolution processing, and improved EMI tolerance—making it ideal for harsh environments in the oil, gas, and petrochemical industries.

Product Parameters

| Parameter | Value |

|---|---|

| Model | 3500/72M |

| Part Number | 176449-08 |

| Dimensions | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.91 kg |

| Channels per Module | 2 |

| Input Type | Proximity probes (e.g., 3300 XL series) |

| Monitoring Range | ±2.0 mm typical |

| Outputs | 4–20 mA analog + Buffered outputs |

| Alarm Setpoints | Configurable for Alert and Danger |

| System Interface | Configurable via 3500/01 or software |

| Power Source | From 3500 rack |

| Mounting | Standard 3500 rack slot |

| Operating Temperature | –30 °C to +65 °C |

| Certifications | CE, ATEX, IEC 61000 compliant |

Product Applications

The 3500/72M 176449-08 is tailored for a wide range of demanding industrial environments where reciprocating compressors are key assets:

-

Gas Compression Stations – Ensures reliable performance of large reciprocating compressors by detecting mechanical degradation in rods and crossheads.

-

Petrochemical Plants – Critical for avoiding unplanned outages due to component wear in reciprocating compressors.

-

Oil Refineries – Monitors key machinery operating under continuous stress in refining operations.

-

LNG Processing Facilities – Supports real-time diagnostics and condition monitoring of reciprocating equipment.

-

Industrial Manufacturing – Enhances mechanical asset longevity through precision rod movement monitoring.

-

Pipeline Transmission Systems – Ensures compressor stations remain operational with early fault detection.

Product Advantages

-

Dual Measurement Capability – Monitors both rod drop and rod position, delivering comprehensive analysis of mechanical health.

-

Advanced Firmware (176449-08) – Provides higher accuracy, resolution, and processing speed compared to earlier models.

-

Buffered and 4–20 mA Outputs – Enables easy integration with DCS, PLCs, and vibration analysis tools.

-

High Compatibility – Seamless use with Bently Nevada 3300 XL proximity transducers.

-

Early Fault Detection – Alerts for misalignment, wear, and crosshead damage before failure occurs.

-

Redundant System Support – Works in critical redundancy configurations for fault-tolerant designs.

-

Compact Rack Integration – Occupies minimal rack space while monitoring two independent channels.

-

Environmentally Hardened – Designed for EMI-resistance and harsh operating conditions.

-

Hot-Swappable – Module can be replaced without shutting down the rack or system.

-

Maintenance Optimization – Enables predictive maintenance, extending compressor life and minimizing downtime.

FAQs

Q1: What specific faults does this module detect?

A1: It detects rod drop, misalignment, wear of piston rods, and crosshead damage in reciprocating compressors.

Q2: How many rod positions can be monitored?

A2: Two independent rod positions can be monitored per module.

Q3: What sensors are required for operation?

A3: It works with Bently Nevada 3300 XL proximity probe systems.

Q4: Does the module offer analog output?

A4: Yes, it provides 4–20 mA current output per channel for system integration.

Q5: Can this module be installed in any 3500 rack?

A5: Yes, it fits standard 3500 series monitoring racks.

Q6: Is the module configurable for alarm settings?

A6: Yes, Alert and Danger levels can be fully configured via system display or software.

Q7: What industries benefit most from this product?

A7: Oil & gas, refining, petrochemicals, LNG, and power generation benefit significantly.

Q8: Is this model an upgrade from previous 72M units?

A8: Yes, version 176449-08 includes updated processing and EMI improvements.

Q9: Is the unit certified for industrial compliance?

A9: Yes, it complies with CE, IEC 61000, and ATEX requirements.

Q10: What is the typical monitoring range?

A10: The typical range is ±2.0 mm for rod position monitoring.

Related Series Models

| Model | Description | Key Features |

|---|---|---|

| 3500/72M 140471-01 | Standard Recip Rod Position Monitor | Dual-channel, earlier firmware version |

| 3500/70M | Recip Compressor Monitor | Crosshead acceleration and load data |

| 3500/61 | Temperature Monitoring Module | Multi-sensor thermal input capability |

| 3500/22M | Transient Data Interface | High-speed data capture |

| 3500/25 | Keyphasor Module | Phase and speed reference |

| 3500/92 | Communication Gateway Module | Ethernet interface for system data |

Popular Bently Nevada Models

| Model | Description | Key Features |

|---|---|---|

| 3500/65-01-01 | 3500 Series temperature monitor with single channel | Single channel, compact design, accurate temperature monitoring |

| 3500/65-02-00 | 3500 Series temperature monitor with dual channels | Dual channel, high precision, ideal for critical systems |

| 3500/70 | 3500 Series alarm module for temperature monitoring | Advanced alarm settings, integrated monitoring capabilities |

| 3500/65-03-00 | 3500 Series multi-channel temperature monitor | Supports 3-4 channels, ideal for multi-point temperature monitoring |

| 3500/65-04-00 | High-performance temperature monitor with additional outputs | Additional output channels for extensive monitoring |

| 3500/70-01 | Industrial alarm module with customizable alarm points | Supports customized alarms, high-temperature applications |

Excellent PLC

Excellent PLC