| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

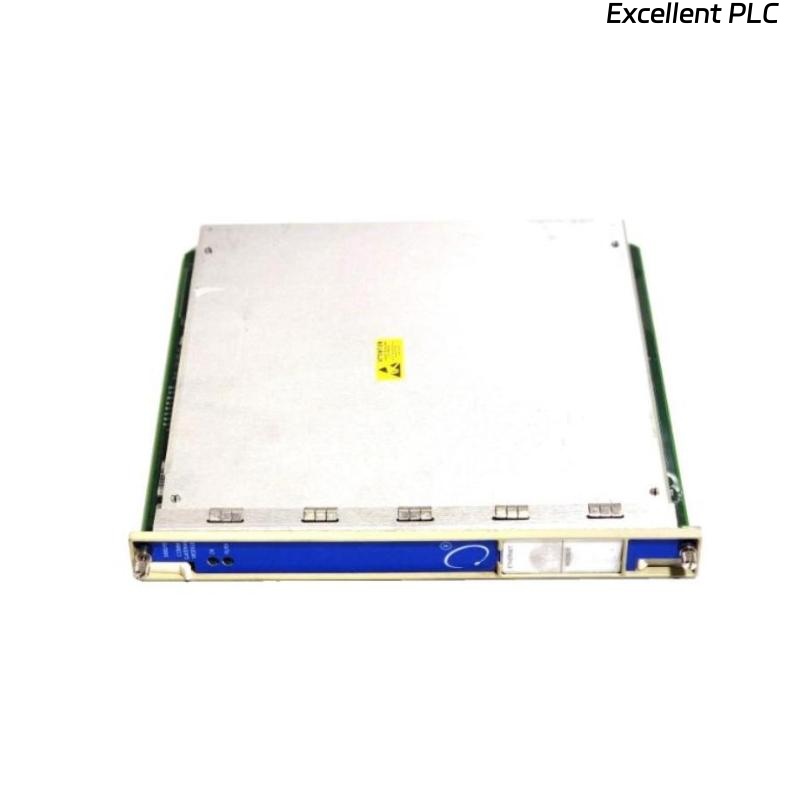

Product Overview

The 3500/91-01-01-02 EGD (Ethernet Gateway Device) Communication Gateway Module is an integral component of the Bently Nevada 3500 Series machinery monitoring systems. It serves as a bridge between Bently Nevada’s monitoring equipment and industrial control systems, such as SCADA, DCS, or PLC systems. By providing real-time, bidirectional communication, it enhances the transfer of critical data like vibration, temperature, pressure, and speed, allowing for better decision-making, predictive maintenance, and fault detection.

This module supports a wide range of communication protocols including Ethernet, Modbus, TCP/IP, and OPC. It ensures the seamless integration of machinery health data into centralized control systems, which is crucial for industries like power generation, oil and gas, manufacturing, and mining.

The 3500/91-01-01-02 is specifically designed to address the need for efficient communication in industrial automation systems, improving system flexibility and reliability. With advanced diagnostic and monitoring capabilities, this module ensures the optimized operation of critical machinery.

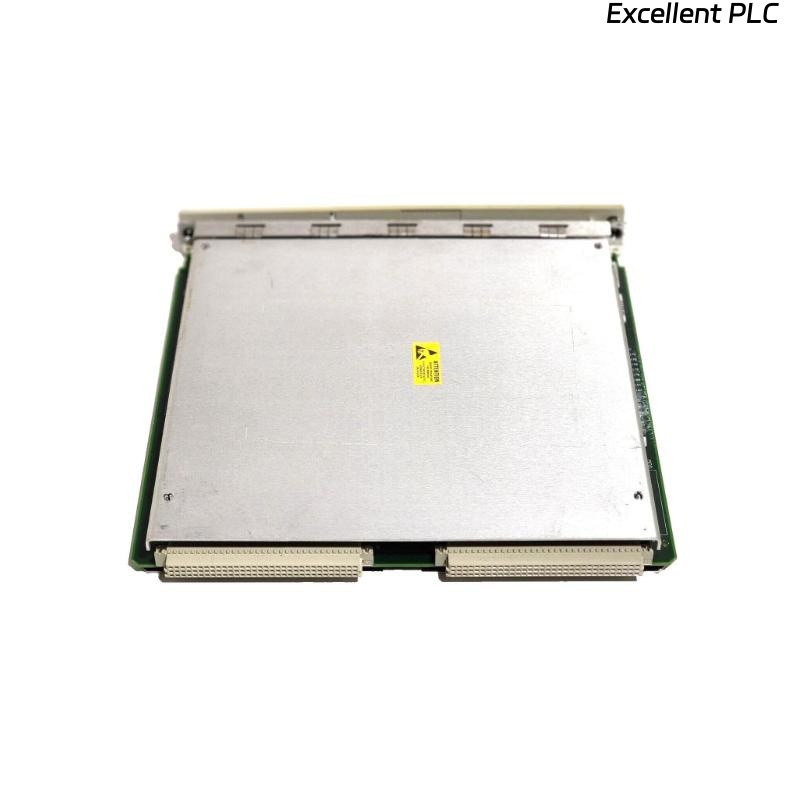

Product Specifications:

| Specification | Details |

|---|---|

| Model | 3500/91-01-01-02 |

| Communication Protocol | Ethernet, Modbus, TCP/IP, OPC |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.79 kg |

| Power Supply | 24 VDC |

| Mounting Type | DIN Rail Mounting |

| I/O Capacity | Up to 10 I/O points |

| Protection Class | IP20 |

| Operating Temperature | -40°C to 85°C |

| Protocols Supported | Modbus, TCP/IP, Ethernet, OPC |

Product Applications:

The 3500/91-01-01-02 EGD Communication Gateway Module is used for integrating machinery health monitoring data with various control systems. Its applications span across multiple industries, including:

-

Power Generation: Seamlessly integrates data from turbines, generators, and other critical equipment into SCADA systems for enhanced monitoring and maintenance.

-

Oil & Gas: Facilitates the connection of pumps, compressors, and valves to control systems, reducing downtime and improving reliability.

-

Heavy Manufacturing: Connects machinery such as motors, conveyors, and HVAC systems to centralized monitoring and control systems.

-

Mining: Enables the continuous monitoring of crushers, excavators, and other large machinery for improved asset management.

-

Industrial Equipment: Assists in monitoring critical machinery, ensuring real-time data visibility and predictive maintenance.

Product Advantages:

-

Wide Compatibility: The module supports several communication protocols, including Ethernet, Modbus, TCP/IP, and OPC, making it versatile and compatible with various industrial control systems.

-

Real-Time Data Integration: It provides real-time data transfer from machinery to central control systems, improving operational efficiency and ensuring quick responses to performance issues.

-

Compact Design: The 3500/91-01-01-02 is compact, with dimensions of 241.3 x 24.4 x 241.8 mm, allowing it to be installed in space-constrained environments.

-

Enhanced Monitoring: The gateway module allows for continuous monitoring of industrial machinery, providing operators with valuable insights for predictive maintenance and troubleshooting.

-

High Scalability: With support for up to 10 I/O points, it can scale with the requirements of different systems, from small to complex applications.

-

Robust and Reliable: With an IP20 protection class and a wide operating temperature range of -40°C to 85°C, the module is durable enough to operate in harsh industrial environments.

-

Easy Integration: The module is designed for DIN rail mounting, simplifying installation and integration into existing control systems.

FAQ:

1. What communication protocols does the 3500/91-01-01-02 support?

The module supports Ethernet, Modbus, TCP/IP, and OPC communication protocols, making it compatible with most industrial control systems.

2. How does the 3500/91-01-01-02 help in predictive maintenance?

By enabling real-time data transfer, the module helps operators identify early signs of equipment failure, allowing for proactive maintenance before issues lead to unplanned downtime.

3. How many I/O points can the 3500/91-01-01-02 handle?

The module can support up to 10 I/O points, making it flexible enough for both smaller and larger systems.

4. What industries can benefit from the 3500/91-01-01-02?

The module is ideal for industries such as power generation, oil and gas, heavy manufacturing, mining, and industrial equipment monitoring.

5. How is the 3500/91-01-01-02 installed?

The module is designed for easy installation with DIN rail mounting, which simplifies the setup process in control panels or cabinets.

6. What is the protection class of the 3500/91-01-01-02?

The module has an IP20 protection class, ensuring protection against dust and foreign objects.

7. Can the 3500/91-01-01-02 be used in harsh environments?

Yes, the module operates within a temperature range of -40°C to 85°C, making it suitable for a wide range of environmental conditions.

8. What are the primary benefits of using this gateway module?

The module improves real-time data integration, enhances monitoring, and enables predictive maintenance, leading to better decision-making and reduced downtime.

9. Is the 3500/91-01-01-02 compatible with SCADA systems?

Yes, the module integrates seamlessly with SCADA systems, allowing for continuous monitoring and better control of industrial machinery.

10. How does the 3500/91-01-01-02 improve operational efficiency?

The real-time communication between machinery and control systems enhances decision-making, reduces manual intervention, and prevents unplanned downtime, all contributing to greater operational efficiency.

Related Product Recommendations:

Same Series or Related Models

| Model | Description |

|---|---|

| 3500/91-01-01-00 | Basic EGD communication gateway for integration with control systems |

| 3500/91-01-01-01 | Enhanced EGD gateway with support for additional protocols |

| 3500/91-02-01 | Communication module designed for high-performance monitoring |

| 3500/92-04-01-00 | Multi-protocol gateway for Ethernet and Modbus-based systems |

| 3500/92-03-01-01 | Advanced gateway for complex control systems integration |

| 3500/91-01-02-00 | Alternative EGD module for low-to-medium complexity systems |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 3500/92-03-01-00 | High-performance multi-protocol gateway with diagnostic capabilities |

| 3500/92-04-01 | Advanced communication gateway for integration with Ethernet and Modbus |

| 3500/92-04-01-00 | Multi-protocol gateway supporting Modbus, TCP/IP, and Ethernet protocols |

| 3500/92-03-01-01 | Communication gateway with enhanced diagnostics for larger industrial systems |

| 3500/92-03-02-00 | Flexible communication module for real-time monitoring of complex systems |

| 3500/92-04-02-01 | High-capacity gateway designed for centralized monitoring across multiple machines |

Excellent PLC

Excellent PLC