| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

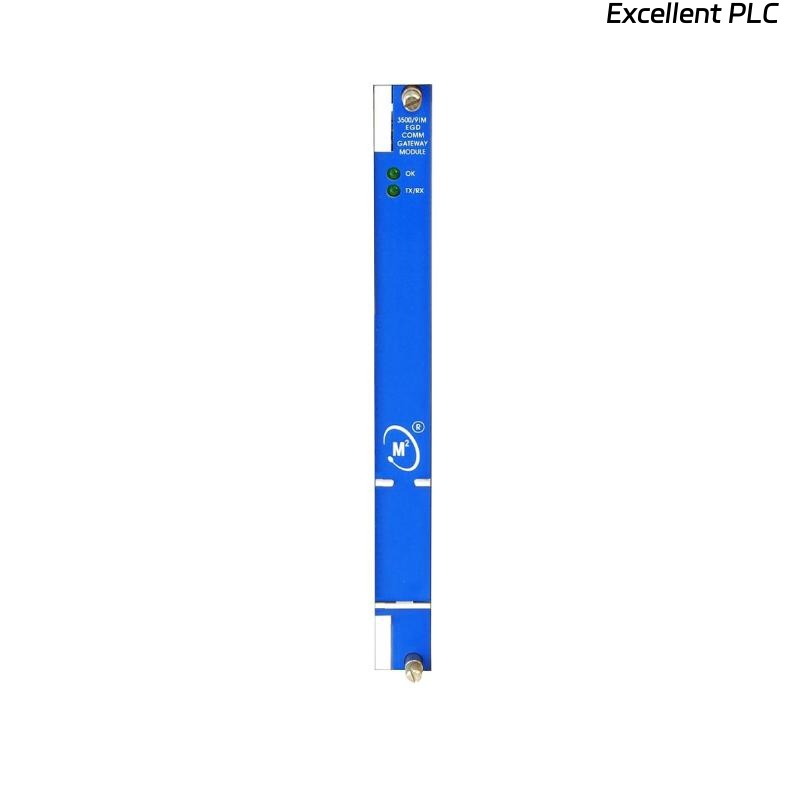

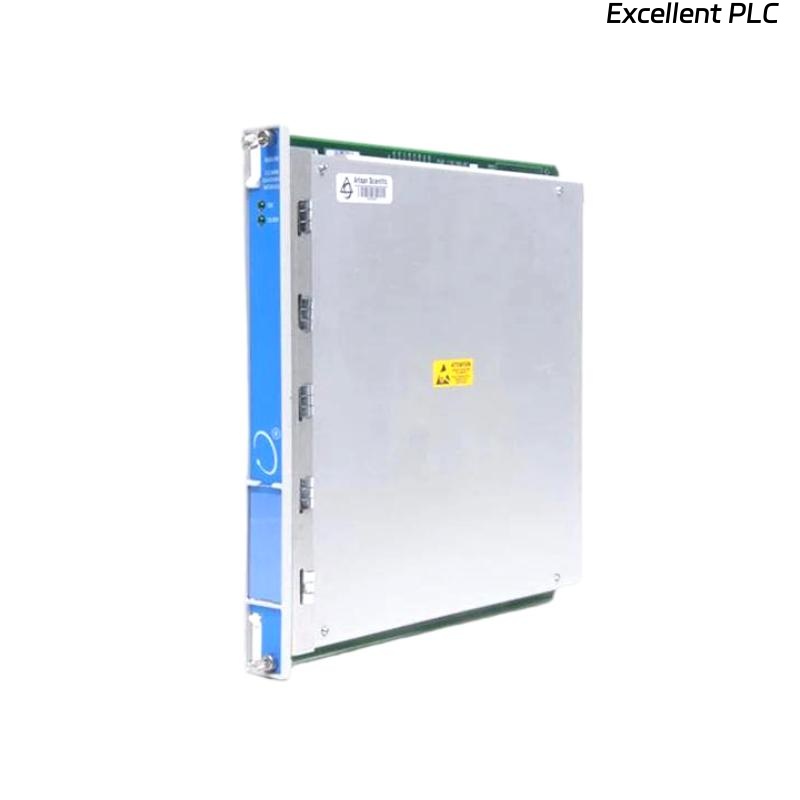

The Bently Nevada 3500/91-01-02-02 EGD Communication Gateway Module is designed for seamless integration between Bently Nevada 3500 Series Machinery Monitoring Systems and external control systems or networks. The EGD (Ethernet Gateway Device) Communication Gateway facilitates the exchange of critical condition monitoring data, such as vibration, temperature, pressure, and speed between the 3500 Series Monitoring Systems and enterprise-level control systems or SCADA networks.

By connecting Bently Nevada equipment with third-party systems, the module enables reliable data exchange, ensuring the real-time accessibility of essential information for predictive maintenance, monitoring, and troubleshooting. This is especially important in industries where maintaining the health of rotating machinery like turbines, generators, compressors, and pumps is critical for operational efficiency.

With support for a range of industrial communication protocols and easy integration into existing infrastructures, the 3500/91-01-02-02 model is ideal for use in power generation, oil and gas, and manufacturing environments where real-time data transfer and machine health analysis are paramount.

Product Specifications:

| Specification | Details |

|---|---|

| Model | 3500/91-01-02-02 |

| Communication Protocol | Ethernet, Modbus, OPC, TCP/IP |

| Dimensions (L x W x H) | 241.3 x 24.4 x 241.8 mm |

| Weight | 0.79 kg |

| Power Supply | 24 VDC |

| Mounting Type | DIN Rail Mounting |

| Compatibility | Compatible with 3500/40 System, 3500/42 |

| I/O Capacity | Up to 10 I/O points |

| Protection Class | IP20 |

| Protocols Supported | Modbus, TCP/IP, Ethernet, OPC |

| Operating Temperature | -40°C to 85°C |

Product Applications:

The 3500/91-01-02-02 EGD Communication Gateway Module is used across various industries to facilitate the integration of Bently Nevada 3500 monitoring systems with broader industrial control systems, such as SCADA, DCS (Distributed Control Systems), or PLC systems.

-

Power Generation: Integrates vibration and temperature monitoring from turbines, generators, and compressors into centralized control systems for real-time diagnostics and proactive maintenance.

-

Oil & Gas: Enables communication between remote monitoring systems on pumps, compressors, and other critical machinery, helping to monitor health status, prevent failures, and reduce downtime.

-

Manufacturing: Integrates machine health data from motors, conveyors, and blowers into SCADA systems for real-time performance monitoring and control.

-

Heavy Machinery: Provides continuous monitoring of equipment such as mining machinery, milling machines, and cranes, ensuring optimized performance and safety.

-

Industrial Equipment: Used for integrating vibration, temperature, and pressure data from various industrial equipment into broader control systems for predictive maintenance.

Product Advantages:

-

Seamless Integration: The 3500/91-01-02-02 facilitates the seamless integration of Bently Nevada monitoring systems with existing industrial control networks, enabling real-time data access.

-

Wide Protocol Compatibility: Supports multiple communication protocols, including Ethernet, Modbus, TCP/IP, and OPC, offering flexibility to integrate with a variety of industrial systems.

-

Compact and Efficient: Its compact design (measuring 241.3 x 24.4 x 241.8 mm) allows for easy installation in equipment racks or control panels, even in space-constrained environments.

-

High Scalability: The 3500/91-01-02-02 supports up to 10 I/O points, making it highly scalable for applications that need to integrate multiple machines into a monitoring system.

-

Durability and Reliability: The module is built to withstand harsh industrial environments, with IP20 protection class offering resistance against dust and dirt.

-

Flexible Mounting: Features DIN rail mounting, which simplifies installation in various industrial control setups.

-

Wide Temperature Range: Capable of operating in temperatures ranging from -40°C to 85°C, making it suitable for diverse environmental conditions.

FAQ:

1. What communication protocols does the 3500/91-01-02-02 module support?

The 3500/91-01-02-02 supports several communication protocols, including Ethernet, Modbus, TCP/IP, and OPC, allowing integration with various industrial control systems.

2. How many I/O points can the 3500/91-01-02-02 module support?

The module can support up to 10 I/O points, making it scalable for larger systems requiring multiple inputs or outputs.

3. Can the 3500/91-01-02-02 module be used in power generation plants?

Yes, the 3500/91-01-02-02 is commonly used in power generation plants to integrate vibration and temperature monitoring systems for turbines, generators, and compressors into control rooms.

4. How is the 3500/91-01-02-02 module mounted?

The module uses DIN rail mounting, which simplifies installation in industrial control panels or equipment racks.

5. Is the 3500/91-01-02-02 module compatible with other Bently Nevada systems?

Yes, the 3500/91-01-02-02 is compatible with 3500/40 and 3500/42 monitoring systems, enabling seamless integration into existing setups.

6. What is the operating temperature range of the 3500/91-01-02-02 module?

The module operates effectively within the temperature range of -40°C to 85°C, making it suitable for a variety of industrial environments.

7. What industries benefit from the 3500/91-01-02-02 module?

The module is ideal for industries like oil and gas, manufacturing, power generation, and heavy machinery, where condition monitoring of rotating equipment is crucial.

8. Can the 3500/91-01-02-02 module help in predictive maintenance?

Yes, by facilitating the transmission of real-time data, the module enables predictive maintenance, helping identify issues before they result in failures or downtime.

9. What is the protection class of the 3500/91-01-02-02 module?

The 3500/91-01-02-02 has an IP20 protection class, which provides resistance against dust and dirt, ensuring long-term durability in industrial environments.

10. How does the 3500/91-01-02-02 improve communication in industrial systems?

It ensures real-time access to condition monitoring data and seamless communication between Bently Nevada monitoring systems and external control networks, improving operational efficiency.

Related Product Recommendations:

Same Series or Related Models

| Model | Description |

|---|---|

| 3500/91-01-02-01 | Basic Communication Gateway for 3500 Series Monitoring |

| 3500/91-02-00-00 | Enhanced Gateway for multiple industrial protocols |

| 3500/40 | Vibration Monitoring System |

| 3500/42 | Multi-Channel Vibration and Temperature Monitor |

| 3500/92 | Communication Gateway for Industrial Systems |

| 3500/93 | System Display for Real-Time Monitoring |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 3500/91-01-01-00 | Basic Communication Gateway with standard protocol support |

| 3500/91-01-01-01 | Advanced Communication Gateway with enhanced features |

| 3500/91-01-02-02 | EGD Communication Gateway with Ethernet and Modbus support |

| 3500/91-01-02-00 | Standard Communication Gateway for remote monitoring |

| 3500/91-02-00-00 | Enhanced gateway with multiple industrial communication protocols |

| 3500/91-03-00-00 | Modular Communication Gateway with integration flexibility |

Excellent PLC

Excellent PLC