| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

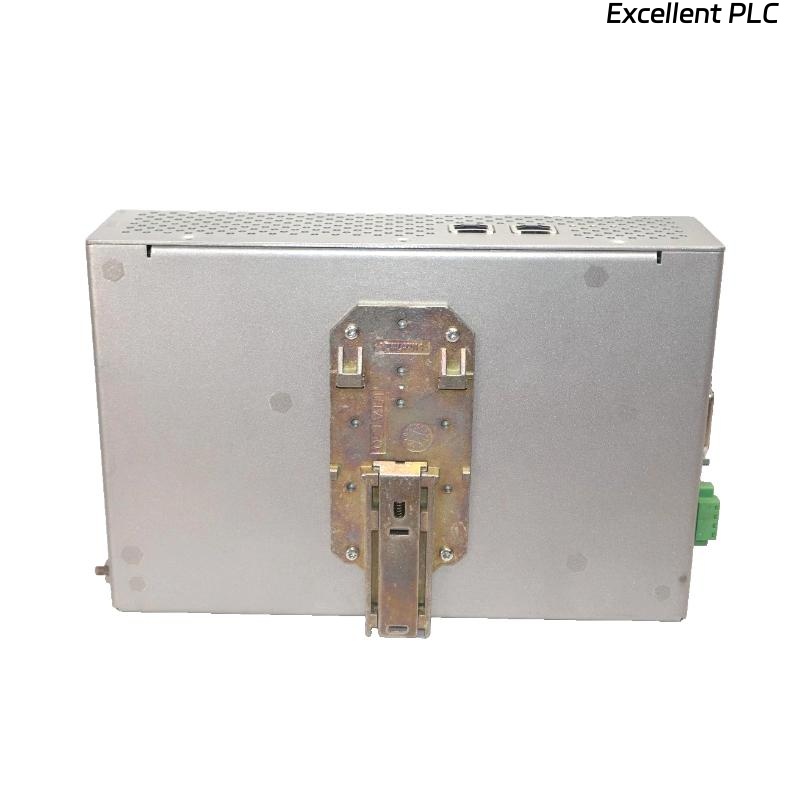

The Bently Nevada 60M100-00 Condition Monitoring System is a high-performance, industrial-grade platform designed to provide continuous and real-time surveillance of rotating machinery and critical plant assets. Developed for industries such as oil & gas, power generation, petrochemical, and heavy manufacturing, the 60M100-00 integrates advanced sensing, data acquisition, and diagnostics into a compact, rugged system. Its modular architecture allows scalable monitoring—from a few key points to a plant-wide network—while delivering precise vibration, temperature, and process data to predictive maintenance software. This reduces unplanned downtime, lowers maintenance costs, and extends equipment life.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Type | Condition Monitoring System |

| Model Number | 60M100-00 |

| System Architecture | Modular, multi-channel |

| Input Channels | Up to 12 vibration or mixed-signal inputs |

| Sensor Compatibility | Proximity probes, accelerometers, RTDs, and 4–20 mA process signals |

| Sampling Rate | 40 kHz per channel (configurable) |

| Dynamic Range | 90 dB |

| Data Interface | Ethernet (TCP/IP), Modbus, OPC UA |

| Alarm/Relay Outputs | 8 programmable relay outputs |

| Power Supply | 24 VDC nominal (range 18–36 VDC) |

| Operating Temperature | –40 °C to +70 °C (–40 °F to +158 °F) |

| Relative Humidity | 5%–95% non-condensing |

| Vibration Resistance | 5 g from 5–2000 Hz |

| Shock Resistance | 30 g, 11 ms half-sine |

| Enclosure Rating | IP65 / NEMA 4X |

| Dimensions (W × H × D) | 225 × 150 × 55 mm |

| Weight | 1.4 kg |

| Compliance | CE, UL, RoHS |

Applications

-

Power Generation: Continuous monitoring of turbines, generators, and auxiliary equipment to prevent costly forced outages.

-

Oil & Gas: Early detection of bearing wear, imbalance, and cavitation in pumps and compressors.

-

Petrochemical Plants: Supervises critical agitators, fans, and process motors under extreme temperatures.

-

Steel & Pulp Mills: Maintains the reliability of high-speed rolls and drives exposed to dust and vibration.

-

Marine & Offshore Platforms: Provides stable performance in salt-laden and humid environments.

-

Predictive Maintenance Programs: Integrates with enterprise software for advanced analytics and machine-learning-driven diagnostics.

Advantages

-

Comprehensive Multi-Parameter Monitoring: Simultaneous measurement of vibration, temperature, and process signals for a holistic view of asset health.

-

High-Speed Data Acquisition: 40 kHz per channel sampling delivers fine-resolution vibration spectra for accurate fault detection.

-

Industrial Durability: Rugged IP65 enclosure protects electronics from moisture, dust, and corrosive agents.

-

Flexible Communication: Ethernet, Modbus, and OPC UA interfaces allow seamless integration into existing SCADA or DCS networks.

-

Advanced Alarming: Configurable alarm logic and 8 relay outputs support automated shutdown and early warnings.

-

Scalable and Modular: Expandable design accommodates future growth in channel count and monitoring requirements.

-

Energy Efficiency: Low 24 VDC power consumption reduces operating costs and simplifies field deployment.

-

Regulatory Compliance: Meets global standards for safety, EMC, and environmental protection.

FAQ

-

What types of sensors are supported by the 60M100-00 Condition Monitoring System?

The system accepts proximity probes, accelerometers, RTDs, and 4–20 mA process transducers for comprehensive machine health measurements. -

How many input channels can be configured simultaneously?

Up to 12 dynamic or mixed-signal channels can be monitored in real time, with each channel independently configurable. -

What is the maximum data sampling rate per channel?

Each channel supports a configurable sampling rate up to 40 kHz, enabling high-resolution vibration spectrum analysis. -

How is the system integrated into plant networks?

Communication options include Ethernet TCP/IP, Modbus, and OPC UA, allowing seamless connectivity to SCADA, DCS, or predictive maintenance platforms. -

What alarm capabilities are provided?

The unit offers eight programmable relay outputs and multiple alarm setpoints per channel to trigger warnings or automatic shutdowns. -

Does the system provide real-time condition diagnostics?

Yes, it continuously analyzes vibration and process data to detect imbalance, misalignment, bearing faults, and other mechanical issues. -

What is the recommended power supply specification?

The module operates at a nominal 24 VDC, with an acceptable input range of 18–36 VDC to accommodate different power conditions. -

Is the 60M100-00 suitable for harsh outdoor environments?

Its IP65/NEMA 4X enclosure provides excellent protection against dust, water, and corrosive atmospheres. -

Can the system be expanded for additional monitoring points?

Yes, the modular design allows future expansion by adding extra input cards or system modules. -

What vibration and shock ratings does the unit meet?

It withstands continuous vibration of 5 g from 5–2000 Hz and shock up to 30 g for 11 ms without performance degradation.

Related Models (Same Series/Family)

| Model Number | Description | Key Feature |

|---|---|---|

| 60M100-01 | Condition Monitoring System with redundant power | Enhanced power reliability |

| 60M100-02 | High-Channel Count Monitoring System | Supports up to 24 channels |

| 60M100-03 | Compact Monitoring System | Reduced enclosure size for tight spaces |

| 60M200-00 | Advanced Condition Monitoring System | Higher processing speed and memory |

| 60M210-00 | Wireless-Ready Condition Monitoring System | Integrated wireless data interface |

| 60M300-00 | Extended-Temperature Condition Monitoring | Operation up to 85 °C (185 °F) |

Popular Bently Nevada Models

| Model Number | Description | Application Focus |

|---|---|---|

| 3500/42M | Proximitor Monitoring Module | Multi-channel vibration and position analysis |

| 330104-00-20-10-02-05 | Proximity Probe | High-accuracy shaft vibration sensing |

| 3500/22M | Transient Data Interface Module | Real-time transient data acquisition |

| 330130-040-00 | Extension Cable | Low-noise signal transmission |

| 3500/40M | Vibration Monitor | Machine protection with four-channel input |

| 330180-51-05 | Velocity Sensor | Seismic and structural vibration detection |

Excellent PLC

Excellent PLC