| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

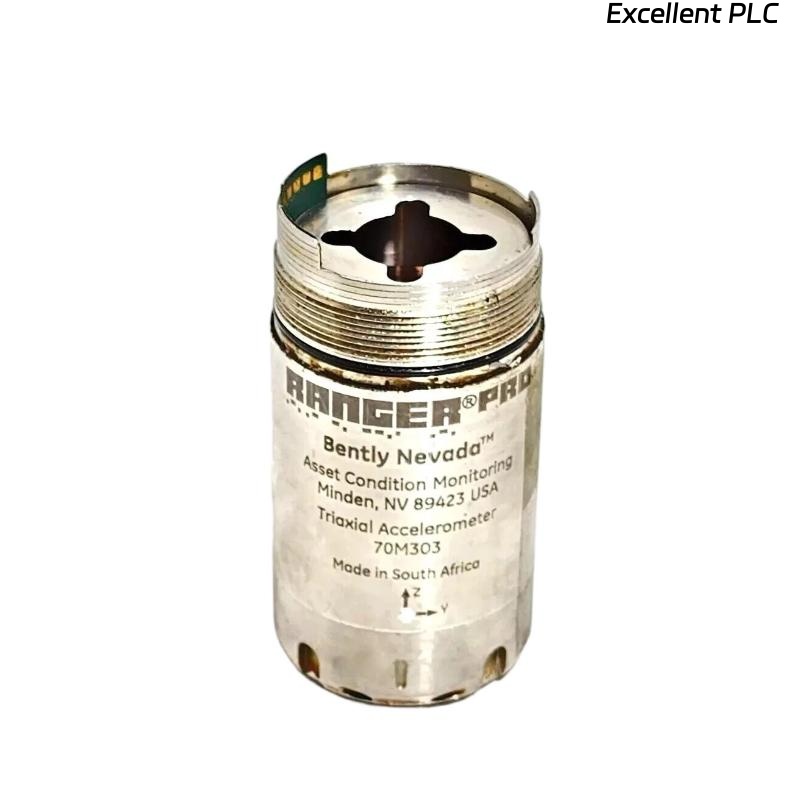

The Bently Nevada 70M303 Ranger Pro Wireless Condition Monitoring Vibration Sensor is a next-generation, high-performance wireless sensor engineered for continuous monitoring of machinery vibration and process health. As a member of the Ranger Pro Wireless family, the 70M303 offers enhanced sensing precision, improved wireless reliability, and expanded dynamic measurement capabilities compared to earlier versions such as the 70M300 and 70M301.

This sensor is specifically designed for industrial-grade asset condition monitoring, providing real-time vibration and temperature data through ISA100 or WirelessHART protocols. It eliminates the need for complex wiring infrastructure, reducing installation costs and enabling scalable deployment across multiple facilities.

Constructed with robust stainless steel housing and fully sealed to withstand oil, dust, and moisture, the 70M303 delivers exceptional performance in extreme industrial environments. It features high-resolution vibration data acquisition up to 10 kHz bandwidth, allowing early detection of bearing wear, imbalance, shaft misalignment, looseness, and other mechanical issues that may lead to unplanned shutdowns.

The 70M303 integrates seamlessly with Bently Nevada System 1† software, enabling centralized monitoring, trend visualization, and automated diagnostic alerts. Designed for both critical and non-critical assets, it supports proactive maintenance strategies that improve operational uptime, reliability, and safety.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 70M303 |

| Product Type | Wireless Vibration and Temperature Monitoring Sensor |

| Measurement Type | Vibration (Acceleration, Velocity, Envelope) + Temperature |

| Sensing Axes | Dual-axis vibration sensing |

| Frequency Response | 1.5 Hz to 10 kHz |

| Vibration Range | ±50 g peak |

| Sampling Rate | 25.6 kHz (typical) |

| Dynamic Range | 100 dB |

| Resolution | 16-bit digital output |

| Integrated Temperature Sensor | Yes (RTD type) |

| Communication Protocol | ISA100 Wireless / WirelessHART |

| Wireless Transmission Range | Up to 250 meters (line-of-sight) |

| Encryption | AES-128 bit secure data encryption |

| Update Interval | Configurable: 1 to 60 minutes |

| Battery Type | Replaceable lithium-thionyl chloride battery |

| Ingress Protection | IP67 / NEMA 4X |

| Operating Temperature Range | -40°C to +125°C |

| Shock Limit | Up to 5000 g peak |

| Material | Stainless steel enclosure with polymer seal |

| Mounting Method | Stud mount, adhesive mount, or magnetic base |

| Certifications | ATEX, IECEx, CSA, CE (hazardous area compliant) |

| Compatible Software | Bently Nevada System 1†, SCADA, DCS |

| Dimensions (H × W × D) | 88 × 40 mm |

| Weight | 0.23 kg |

Product Applications

Typical Applications Include:

-

Rotating Equipment: Motors, pumps, compressors, fans, and turbines.

-

Oil & Gas Industry: Continuous vibration monitoring of offshore and onshore rotating assets in explosive or remote environments.

-

Power Generation: Detection of imbalance, bearing wear, and misalignment in generators and cooling systems.

-

Petrochemical and Refining: Monitoring of process-critical pumps, agitators, and blowers.

-

Mining and Cement Plants: Reliable monitoring in dusty, vibration-intensive environments.

-

Water and Wastewater: Ensures operational reliability of aerators, mixers, and pumping systems.

-

Manufacturing Plants: Ideal for predictive maintenance of critical production line components.

The 70M303 allows seamless data integration into enterprise systems, enabling centralized diagnostics, reduced maintenance overhead, and enhanced decision-making based on real-time condition data.

Product Advantages

-

Dual-Axis High-Precision Measurement: Offers accurate vibration analysis in multiple directions for superior diagnostics.

-

Wireless and Scalable Design: Eliminates wiring complexity and allows flexible deployment across large industrial areas.

-

High Dynamic Range: Captures both low-level and high-impact vibration events without data distortion.

-

Integrated Temperature Monitoring: Provides thermal data for complete machine condition insight.

-

Durable Construction: Stainless steel body with IP67 protection ensures long-term reliability in harsh conditions.

-

Low Maintenance Operation: Long-life battery design minimizes manual intervention.

-

Certified for Hazardous Locations: Complies with ATEX, IECEx, and CSA standards for safe use in explosive areas.

-

Secure Communication: Uses industrial-grade AES-128 encryption for data security.

-

Flexible Mounting Options: Can be installed using magnetic, adhesive, or stud mounts.

-

System 1 Integration: Fully compatible with Bently Nevada’s System 1† software for real-time diagnostics and trending.

FAQ

1. What type of sensors are integrated into the 70M303?

It includes dual-axis vibration sensors and an integrated RTD temperature sensor for comprehensive asset condition monitoring.

2. How is data transmitted from the sensor?

The 70M303 transmits vibration and temperature data wirelessly via ISA100 or WirelessHART industrial communication standards.

3. What is the typical update interval for vibration readings?

The transmission interval is configurable, ranging from 1 minute up to 60 minutes, depending on system requirements.

4. Can the sensor handle high-frequency vibration measurements?

Yes, it supports a wide frequency response from 1.5 Hz up to 10 kHz, suitable for both slow and fast rotating machinery.

5. What is the maximum acceleration range the sensor can measure?

It can measure vibrations up to ±50 g peak, allowing accurate detection of severe mechanical conditions.

6. Does the sensor support simultaneous temperature and vibration monitoring?

Yes, the integrated RTD sensor enables simultaneous temperature data acquisition with vibration monitoring.

7. Is the 70M303 compatible with System 1 software?

Yes, it integrates seamlessly with Bently Nevada System 1† for data analysis, trending, and diagnostics.

8. How secure is the wireless data transmission?

It uses AES-128 encryption to ensure secure, tamper-resistant communication across industrial networks.

9. Can the sensor be used in explosive or hazardous environments?

Yes, the device is fully certified under ATEX, IECEx, and CSA standards for safe use in hazardous locations.

10. What mounting options are available for the 70M303?

The sensor can be mounted using a stud, adhesive pad, or magnetic base depending on the machinery type and installation conditions.

Related Models (Same Series or Family)

| Model | Description |

|---|---|

| 70M300 | Standard Ranger Pro wireless vibration and temperature sensor with single-axis measurement |

| 70M301 | Enhanced wireless sensor with improved vibration precision and temperature measurement |

| 70M302 | Dual-axis version optimized for multi-directional vibration detection |

| 70M304 | Compact model for limited-space installations |

| 70M305 | Explosion-proof variant for hazardous locations |

| 70M306 | Extended battery life version for long-term wireless deployments |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500/40M | Proximitor monitor for shaft vibration and position measurement |

| 3500/42M | Dual-channel vibration and position monitoring module |

| 3500/93 | Power supply module for 3500 rack systems |

| 3300 XL 8mm Probe | Standard proximity probe for shaft vibration detection |

| 3500/22M | Transient data interface for dynamic machinery diagnostics |

| 330400 Velomitor Sensor | Velocity sensor for low-frequency vibration monitoring |

Excellent PLC

Excellent PLC