| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

The Bently Nevada 70M323 Ranger Pro Wireless Condition Monitoring Vibration Sensor represents one of the most advanced solutions in wireless machine condition monitoring. Designed to meet the needs of modern industrial environments, this sensor combines high-performance vibration measurement, temperature sensing, and secure wireless communication in a compact and durable form factor.

Belonging to the Ranger Pro Wireless series, the 70M323 offers enhanced accuracy, extended frequency bandwidth, and superior battery efficiency compared to earlier models such as the 70M301 and 70M303. It is specifically engineered for continuous monitoring of rotating and reciprocating machinery, providing critical insight into vibration signatures that can indicate imbalance, misalignment, bearing faults, or gear wear.

The 70M323 utilizes either ISA100 or WirelessHART communication protocols, ensuring reliable data transmission across complex industrial networks. It operates seamlessly with Bently Nevada’s System 1† software, enabling comprehensive data visualization, trending, and diagnostics for proactive maintenance and reduced unplanned downtime.

Built with a stainless steel enclosure and IP67-rated sealing, the sensor withstands severe industrial conditions such as oil, moisture, vibration, and temperature extremes. This makes it ideal for industries including oil & gas, power generation, petrochemical processing, mining, and manufacturing.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 70M323 |

| Product Type | Wireless Vibration and Temperature Sensor |

| Measurement Parameters | Vibration (Acceleration, Velocity, Envelope), Temperature |

| Sensing Axes | Dual-axis |

| Frequency Response | 1.5 Hz to 10 kHz |

| Vibration Measurement Range | ±50 g peak |

| Resolution | 16-bit digital output |

| Sampling Rate | 25.6 kHz typical |

| Dynamic Range | 100 dB |

| Temperature Measurement Range | -40°C to +125°C |

| Integrated Temperature Sensor | RTD-based (for high accuracy) |

| Communication Protocol | ISA100 Wireless / WirelessHART |

| Wireless Transmission Range | Up to 250 meters (line-of-sight) |

| Encryption Standard | AES-128 industrial-grade encryption |

| Update Interval | Configurable from 1 minute to 60 minutes |

| Power Source | Replaceable lithium-thionyl chloride battery |

| Material | Stainless steel body with polymer isolation layer |

| Ingress Protection | IP67 / NEMA 4X |

| Shock Limit | Up to 5000 g |

| Certifications | ATEX, IECEx, CSA, CE |

| Compatible Software | Bently Nevada System 1†, DCS, SCADA |

| Mounting Options | Stud mount, adhesive, or magnetic base |

| Dimensions (H × W × D) | 100 × 40 mm |

| Weight | 0.4 kg |

Product Applications

The Bently Nevada 70M323 Ranger Pro Wireless Condition Monitoring Sensor is used across a wide spectrum of industrial applications that demand reliable and continuous machine health monitoring. By providing vibration and temperature data in real time, it helps operators identify mechanical anomalies before they result in costly failures.

Key Application Areas Include:

-

Rotating Equipment: Motors, fans, pumps, turbines, compressors, and gearboxes.

-

Oil & Gas Production: Vibration monitoring of drilling equipment, pumps, and compressors in remote or hazardous environments.

-

Power Generation: Monitoring turbine generators, cooling fans, and drive motors.

-

Petrochemical Plants: Detecting early-stage bearing and seal wear in refinery pumps.

-

Mining and Cement Processing: Monitoring crushers, mills, and conveyors for mechanical imbalance.

-

Water and Wastewater Management: Ensuring performance of aerators, pumps, and agitators.

-

Manufacturing and Automation: Tracking health of robotic arms, conveyors, and rotating spindles.

Through its integration with System 1†, the 70M323 provides full digital connectivity, allowing predictive maintenance, alarm management, and optimized asset utilization.

Product Advantages

-

Dual-Axis Vibration Measurement: Provides high-resolution vibration data in both vertical and horizontal directions for comprehensive analysis.

-

Wireless Data Transmission: Eliminates wiring complexity, simplifies installation, and reduces maintenance costs.

-

High Dynamic Range and Accuracy: Enables precise detection of vibration anomalies even in low-amplitude conditions.

-

Integrated Temperature Sensing: Simultaneous vibration and temperature monitoring for enhanced machine health diagnostics.

-

Rugged and Reliable Design: Stainless steel enclosure with IP67 protection resists dust, oil, and moisture intrusion.

-

Long Battery Life: Up to 5 years of autonomous operation depending on reporting interval.

-

Hazardous Area Certification: Fully compliant with ATEX, IECEx, and CSA for explosive environments.

-

Secure Communication: Employs AES-128 encryption for data integrity and cybersecurity.

-

Flexible Mounting: Compatible with multiple installation methods for diverse applications.

-

Full System Integration: Seamless connection with Bently Nevada System 1† software for centralized monitoring and diagnostics.

FAQ

1. What type of vibration data does the 70M323 collect?

It collects acceleration, velocity, and envelope vibration data, enabling comprehensive mechanical health evaluation.

2. How many axes of vibration does this sensor measure?

The 70M323 provides dual-axis sensing for both horizontal and vertical measurements.

3. What is the typical sampling rate for vibration analysis?

The device samples vibration data at approximately 25.6 kHz, allowing high-resolution spectral analysis.

4. Can the update frequency be configured by the user?

Yes, users can configure data update intervals between 1 and 60 minutes depending on monitoring requirements.

5. What wireless communication protocols are supported?

The sensor supports both ISA100 Wireless and WirelessHART protocols for secure and reliable data transmission.

6. What is the vibration measurement range of the 70M323?

It can measure up to ±50 g peak acceleration, suitable for both low- and high-vibration applications.

7. Is the sensor capable of detecting bearing or gear wear?

Yes, with its wide frequency response (1.5 Hz to 10 kHz), it can identify early signs of bearing damage and gear meshing issues.

8. Does the 70M323 provide simultaneous temperature monitoring?

Yes, it features an integrated RTD temperature sensor that measures equipment surface temperature in real time.

9. How secure is the data transmission?

The sensor uses AES-128 encryption, ensuring that all transmitted data remains secure and tamper-proof.

10. Can it be integrated with existing asset management systems?

Yes, it is fully compatible with Bently Nevada’s System 1† software and can also integrate with SCADA or DCS systems.

Related Models (Same Series or Family)

| Model | Description |

|---|---|

| 70M300 | Standard Ranger Pro wireless vibration and temperature sensor |

| 70M301 | Enhanced precision version with single-axis vibration measurement |

| 70M302 | Dual-axis wireless sensor with improved bandwidth and signal clarity |

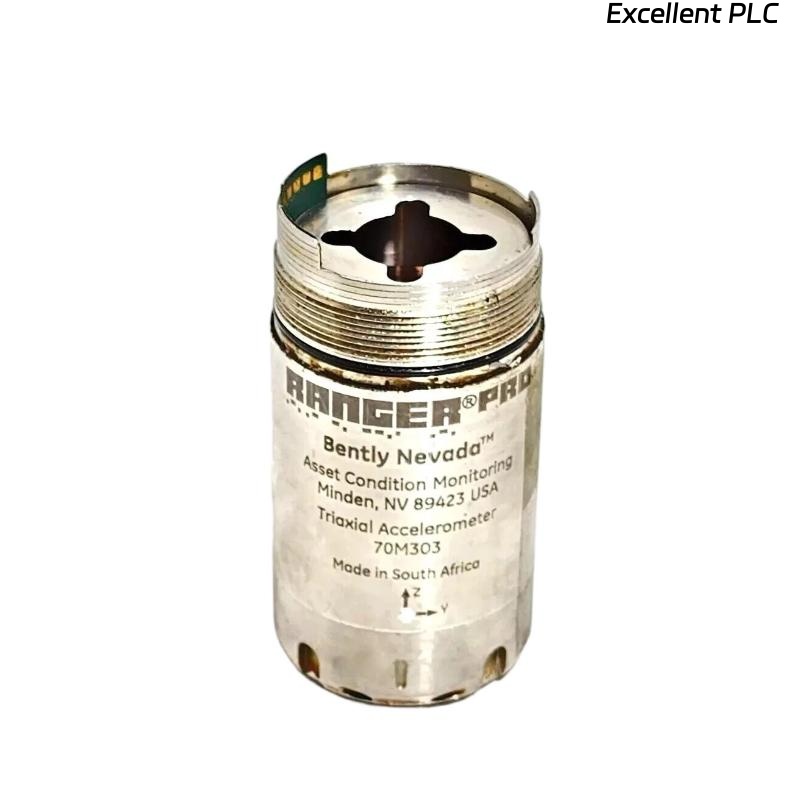

| 70M303 | Advanced version supporting high-resolution vibration analysis |

| 70M304 | Compact model for limited installation spaces |

| 70M305 | Explosion-proof model designed for hazardous environments |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3500/42M | Dual-channel vibration and position monitoring module |

| 3500/40M | Proximitor monitor for shaft vibration and position measurement |

| 3500/22M | Transient data interface for advanced diagnostics |

| 3500/93 | Power supply module for 3500 series racks |

| 3300 XL 8mm Probe | Standard proximity probe for shaft vibration detection |

| 330400 Velomitor Sensor | Velocity sensor for low-frequency vibration monitoring |

Excellent PLC

Excellent PLC