| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

The Bently Nevada 70M403 Ranger Pro Wireless Condition Monitoring Vibration Sensor is an advanced wireless sensing device designed for continuous, high-accuracy monitoring of machine vibration and temperature. Developed as part of the Ranger Pro series, this model provides a reliable, low-maintenance solution for asset condition monitoring in harsh and industrial environments. It integrates seamlessly with Bently Nevada’s System 1 and other predictive maintenance platforms, offering real-time data analytics to improve operational reliability and reduce unplanned downtime.

The 70M403 model is engineered to support modern industrial IoT frameworks, allowing wireless communication using industry-standard protocols such as ISA100 or WirelessHART. This makes it ideal for remote or hard-to-reach assets where wired installations are difficult or costly. Built with robust materials and encapsulated electronics, it withstands high vibration levels, temperature variations, and environmental exposure common in refineries, power plants, and manufacturing facilities.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 70M403 Ranger Pro Wireless Vibration Sensor |

| Measurement Type | Vibration and Temperature |

| Frequency Range | 2 Hz to 10 kHz |

| Vibration Range | ±50 g peak |

| Resolution | 16-bit |

| Sampling Rate | Up to 25.6 kHz |

| Communication Protocol | ISA100 / WirelessHART |

| Transmission Range | Up to 200 meters (line-of-sight) |

| Power Source | Industrial lithium battery (replaceable) |

| Temperature Measurement Range | -40°C to +125°C |

| Ingress Protection | IP67 |

| Material | Stainless steel housing with epoxy sealing |

| Mounting Type | Stud or magnetic base |

| Operating Voltage | 3.6 V DC internal supply |

| Operating Humidity | 0–95% non-condensing |

| Integration | Compatible with Bently Nevada System 1 software |

| Dimensions | 88 × 40 mm |

| Weight | 0.23 kg |

Applications

The Bently Nevada 70M403 is designed for a wide range of industrial applications where vibration and temperature data are critical to predictive maintenance. Common applications include:

-

Rotating machinery such as compressors, turbines, and motors.

-

Pumps and fans, where vibration levels indicate early signs of imbalance or bearing wear.

-

Gearboxes and transmission systems requiring continuous performance tracking.

-

Power generation plants, including gas, steam, and hydroelectric units.

-

Petrochemical and refinery environments, monitoring critical rotating assets.

-

Mining and cement industries, for rugged and remote monitoring conditions.

Its wireless capability eliminates the need for extensive cabling, reducing installation time and maintenance costs while maintaining continuous data availability.

Product Advantages

-

Wireless Efficiency: Reduces installation complexity and costs by removing the need for hardwired connections.

-

Advanced Data Accuracy: High-resolution vibration and temperature measurement enables precise diagnostics.

-

Long-Term Reliability: Durable stainless-steel construction with IP67 protection ensures long operational life in demanding environments.

-

Seamless Integration: Fully compatible with Bently Nevada System 1 and other data acquisition systems.

-

Enhanced Predictive Maintenance: Supports condition-based monitoring strategies, minimizing unplanned downtime.

-

Flexible Configuration: Adjustable sampling intervals, sensitivity, and transmission settings for various machinery types.

-

Energy Efficient: Optimized for low-power operation with extended battery life up to five years.

-

Scalable Solution: Easily expanded across plant networks to cover hundreds of machines.

-

Safety and Compliance: Designed for use in hazardous environments with certifications for industrial safety standards.

-

Global Connectivity: Supports integration with wireless mesh networks for broad area coverage.

FAQ

1. What type of wireless protocol does the 70M403 sensor use?

The 70M403 supports both ISA100 and WirelessHART protocols, allowing flexible integration with various industrial wireless systems.

2. How is the vibration data processed within the sensor?

The sensor includes built-in signal conditioning and digital filtering to perform FFT-based analysis before transmitting data to the monitoring system.

3. Can the 70M403 integrate directly with Bently Nevada System 1 software?

Yes, it integrates seamlessly with the System 1 platform for real-time vibration monitoring, diagnostics, and performance trending.

4. What is the maximum sampling rate supported by this sensor?

The 70M403 supports sampling rates up to 25.6 kHz, enabling high-resolution vibration waveform capture and spectral analysis.

5. How does the sensor maintain stable communication in noisy industrial environments?

It utilizes frequency-hopping and data integrity verification algorithms to ensure robust communication even in areas with high electromagnetic interference.

6. Does the sensor support remote firmware updates?

Yes, firmware can be updated over-the-air (OTA) via the wireless network, ensuring minimal downtime and easy maintenance.

7. What mechanisms are used to extend battery life in continuous monitoring applications?

The device employs intelligent duty cycling and adaptive wake-up intervals to balance performance with low power consumption.

8. How does the 70M403 ensure accuracy under varying temperature conditions?

It features built-in temperature compensation algorithms that maintain consistent vibration measurement accuracy across a wide temperature range.

9. Is the 70M403 suitable for hazardous or explosive environments?

Yes, it can be supplied with hazardous area certifications, making it safe for use in oil, gas, and chemical processing facilities.

10. How can vibration data be synchronized across multiple wireless sensors?

The System 1 software synchronizes timestamped data across multiple 70M403 sensors to ensure precise trend comparison and coordinated analysis.

Related Models (Same Series)

| Model | Description | Measurement Range | Communication | Weight |

|---|---|---|---|---|

| 70M300 | Ranger Pro Wireless Vibration Sensor | ±25 g | ISA100 | 0.38 kg |

| 70M301 | Ranger Pro Wireless Vibration & Temp Sensor | ±50 g | WirelessHART | 0.40 kg |

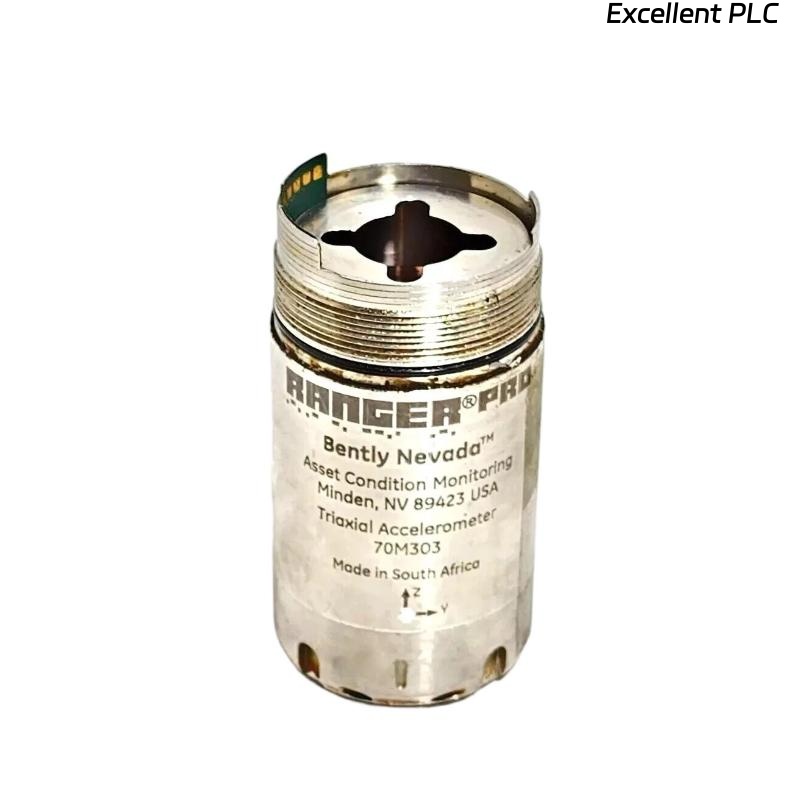

| 70M303 | Ranger Pro Dual-Axis Vibration Sensor | ±50 g | ISA100 | 0.42 kg |

| 70M323 | Ranger Pro High-Frequency Sensor | ±80 g | WirelessHART | 0.44 kg |

| 70M403 | Ranger Pro Extended Range Sensor | ±50 g | ISA100 | 0.42 kg |

| 70M420 | Ranger Pro Tri-Axial Wireless Sensor | ±80 g | WirelessHART | 0.45 kg |

Popular Models from Bently Nevada

| Model | Product Type | Application | Communication Type | Weight |

|---|---|---|---|---|

| 330104-00-10-10-02-00 | 3300 XL Proximity Probe | Shaft vibration monitoring | Wired | 0.22 kg |

| 330105-02-12-10-02-00 | 3300 XL Probe | Turbine and motor shaft monitoring | Wired | 0.25 kg |

| 330130-045-00-05 | 3300 XL Extension Cable | Proximity probe connection | Wired | 0.30 kg |

| 3500/42M | Vibration Monitor Module | Machinery protection systems | Rack-based | 0.45 kg |

| 3500/22M | Transient Data Interface | Advanced condition monitoring | Rack-based | 0.50 kg |

| 3500/20 | Rack Interface Module | System communication management | Rack-based | 0.40 kg |

Excellent PLC

Excellent PLC