| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

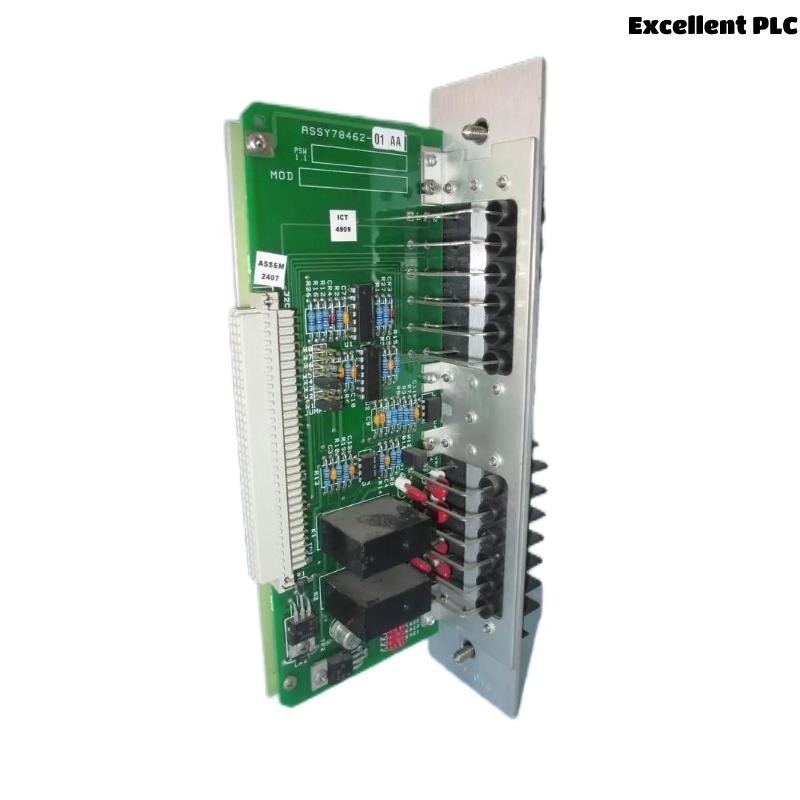

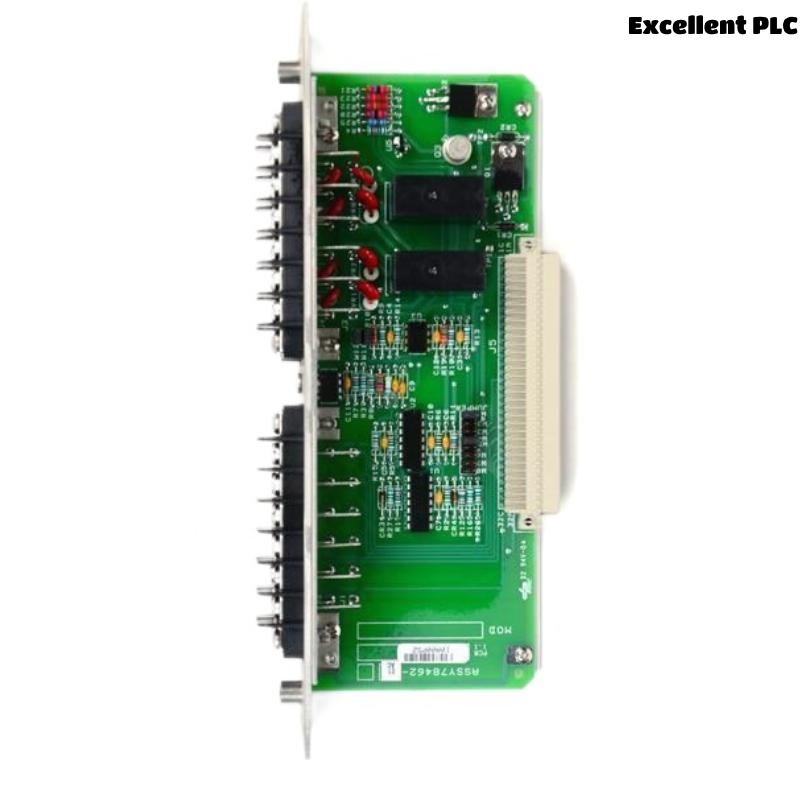

Product Overview

The Bently Nevada 78462-01 3300 Relay Module with Conformal Coating is a key component of the Bently Nevada 3300 Series Machinery Protection System, designed to provide reliable relay outputs for critical alarm, shutdown, and machine protection functions.

This relay module converts monitored vibration or process signals into relay contact closures, triggering alarms or control actions based on pre-defined system conditions. The Conformal Coating version enhances the module’s durability by protecting sensitive electronics against harsh industrial environments, including moisture, dust, and corrosive contaminants.

With its robust design, high reliability, and seamless integration into the 3300 system, the 78462-01 Relay Module is essential for safeguarding rotating machinery such as turbines, compressors, pumps, and generators in demanding industrial settings.

Key Features

-

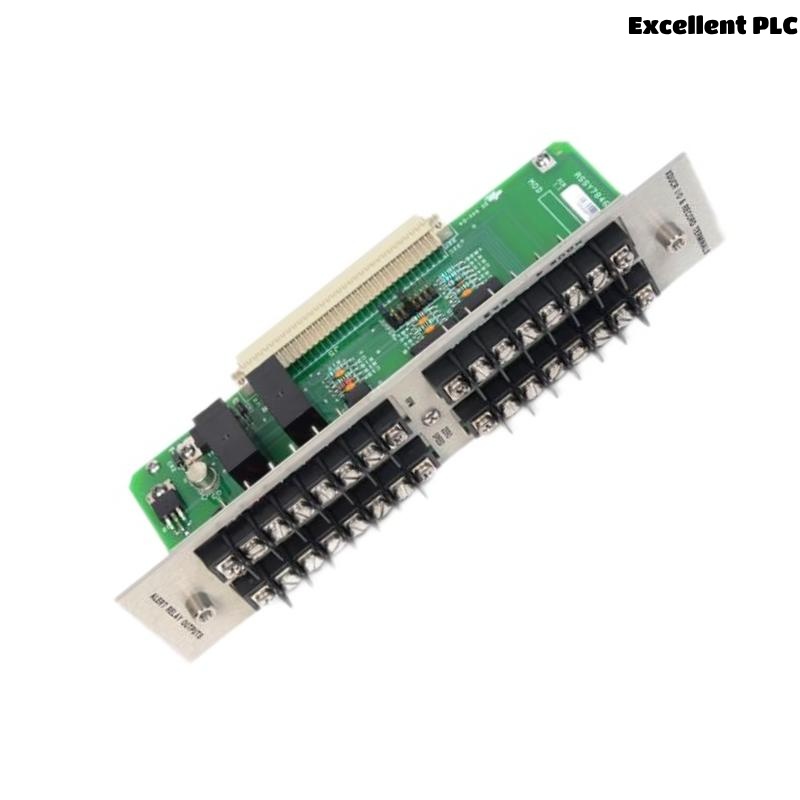

Relay Output for Alarms and Shutdowns: Provides contact closures based on monitoring system conditions

-

Conformal Coating Protection: Enhanced resistance to moisture, dust, and chemical contaminants

-

Seamless 3300 Series Integration: Works within Bently Nevada’s established 3300 monitoring platform

-

High Reliability Switching: Designed for mission-critical machine protection applications

-

Flexible Relay Configurations: Supports system alarm, danger, or shutdown relay logic

-

Industrial Durability: Engineered for continuous operation in harsh process environments

-

Compact Form Factor: Easily fits into standard 3300 system racks

-

Electrical Isolation: Protects against electrical noise and ground faults

-

Field-Proven Performance: Trusted in industries requiring the highest standards of safety and reliability

Technical Specifications

| Parameter | Description |

|---|---|

| Product Name | Relay Module with Conformal Coating |

| Model Number | 78462-01 |

| System Compatibility | Bently Nevada 3300 Series Machinery Protection Systems |

| Relay Type | Electromechanical or Solid-State (system dependent) |

| Number of Relays | Typically 4 relays per module (application specific) |

| Contact Ratings | 5A @ 30 VDC, 5A @ 250 VAC resistive load |

| Electrical Isolation | Provided between input circuits and relay contacts |

| Environmental Protection | Conformal Coating for enhanced durability |

| Operating Voltage | Supplied by 3300 system rack |

| Operating Temperature Range | -20°C to +65°C |

| Storage Temperature Range | -40°C to +85°C |

| Humidity Tolerance | 95% non-condensing |

| Certifications | CE, UL, CSA, ATEX, IECEx (installation dependent) |

| Dimensions | 180 x 100 x 80mm |

| Weight | 0.7 kg |

Product Advantages

-

Critical Alarm and Protection Relay Outputs: Provides reliable relay actions for machinery shutdown, alarms, and protective interlocks

-

Enhanced Environmental Protection: Conformal coating safeguards electronic circuits against moisture, dust, and corrosive atmospheres

-

Seamless System Integration: Designed specifically for Bently Nevada 3300 Series monitoring racks

-

High-Reliability Design: Ensures dependable performance in demanding, safety-critical industrial applications

-

Flexible Application Support: Accommodates a variety of relay configurations to meet specific machine protection requirements

-

Electrical Safety and Isolation: Minimizes risks from electrical interference or faults in control circuits

-

Compact and Maintainable: Easily installed, replaced, or serviced within standard 3300 system frames

-

Field-Tested Performance: Proven reliability in oil & gas, power generation, refining, and other critical industries

Industry Applications

The Bently Nevada 78462-01 Relay Module is ideal for industries where continuous machinery protection and reliable system responses are required:

-

Oil & Gas Production and Processing

-

Power Generation (Thermal, Nuclear, Hydro, Renewables)

-

Petrochemical and Refining Plants

-

Metals, Mining, and Minerals Processing

-

Marine and Offshore Platforms

-

Water and Wastewater Infrastructure

-

Pulp and Paper Manufacturing

-

Industrial Machinery OEM Integration

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the 78462-01 Relay Module?

It provides relay outputs for alarms, shutdowns, and protection logic in the Bently Nevada 3300 machinery monitoring system.

Q2: What does Conformal Coating add to the module?

The coating protects the electronic circuitry from moisture, dust, and corrosive substances, improving reliability in harsh environments.

Q3: Can the relay module be replaced while the system is online?

Depending on the system configuration, the module may be hot-swappable. Refer to site-specific procedures.

Q4: What type of relays are used?

The module may use electromechanical or solid-state relays, depending on application requirements.

Q5: What are typical relay contact ratings?

5A at 30 VDC or 250 VAC for resistive loads.

Q6: How does the module integrate with the 3300 system?

It mounts directly into the 3300 system rack and interfaces with monitoring modules to execute alarm and shutdown commands.

Q7: Is the module suitable for hazardous environments?

Yes, when installed within certified systems, it complies with ATEX, IECEx, and other standards for hazardous locations.

Q8: What maintenance does the relay module require?

Minimal; visual inspection, functionality tests, and periodic relay operation verification are recommended.

Q9: Can this module handle both alarm and shutdown functions?

Yes, relay outputs can be configured for different system conditions, including alarms and automatic shutdowns.

Q10: What industries commonly use this relay module?

It is used across oil & gas, power generation, petrochemical, mining, marine, and other industrial sectors.

Recommended Related Models

| Model Number | Description |

|---|---|

| 78462-02 | 3300 Relay Module with alternative relay configuration |

| 3300/16-15-01-01-00 | 3300 System Power Supply Module |

| 330104-00-05-10-02-05 | 3300 XL 8mm Proximity Probe for displacement monitoring |

| 330130-040-00-05 | 3300 XL Extension Cable for Proximity Probe Systems |

| 330500-01-00 | Velomitor® Velocity Sensor for general vibration monitoring |

| 3300/03 | 3300 Rack Frame for system module installation |

Popular Bently Nevada Machinery Protection Products

| Model Number | Description |

|---|---|

| 3500/25 128718-01 | Keyphasor® Module with External Terminal Connections |

| 3500/22M 164466-01 | Ethernet Transient Data Interface for 3500 System |

| 3500/42M | Advanced Vibration Monitoring Module |

| 330101-00-20-05-02-05 | 3300 XL 8mm Proximity Probe for precise displacement measurement |

| 3500/15-05-05-00 | Power Supply Module for Bently Nevada 3500 System |

| ADAPT 3701/55 | Adaptive Machine Protection and Condition Monitoring System |

Excellent PLC

Excellent PLC