| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

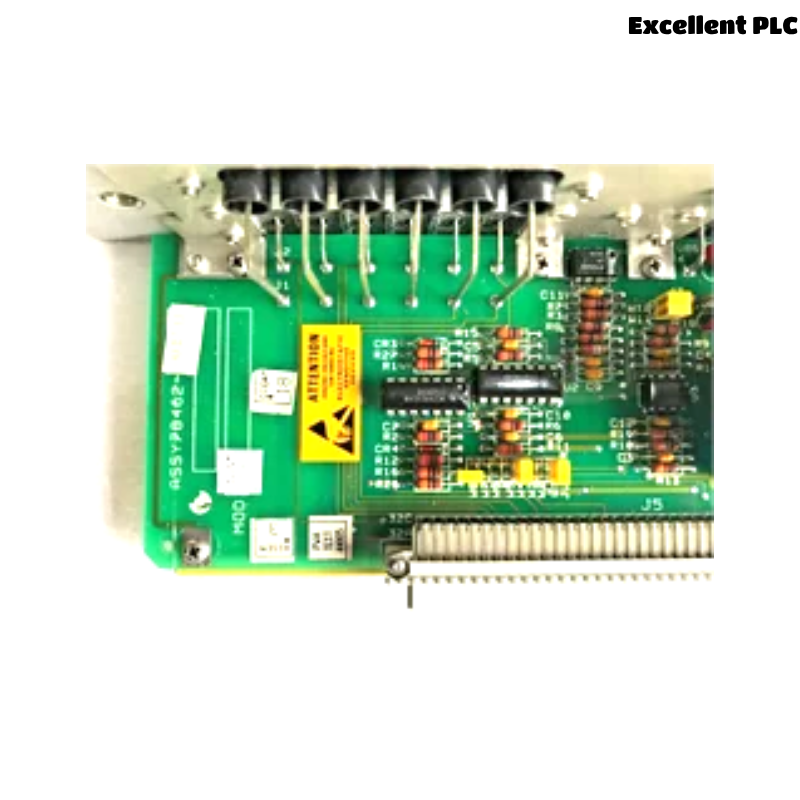

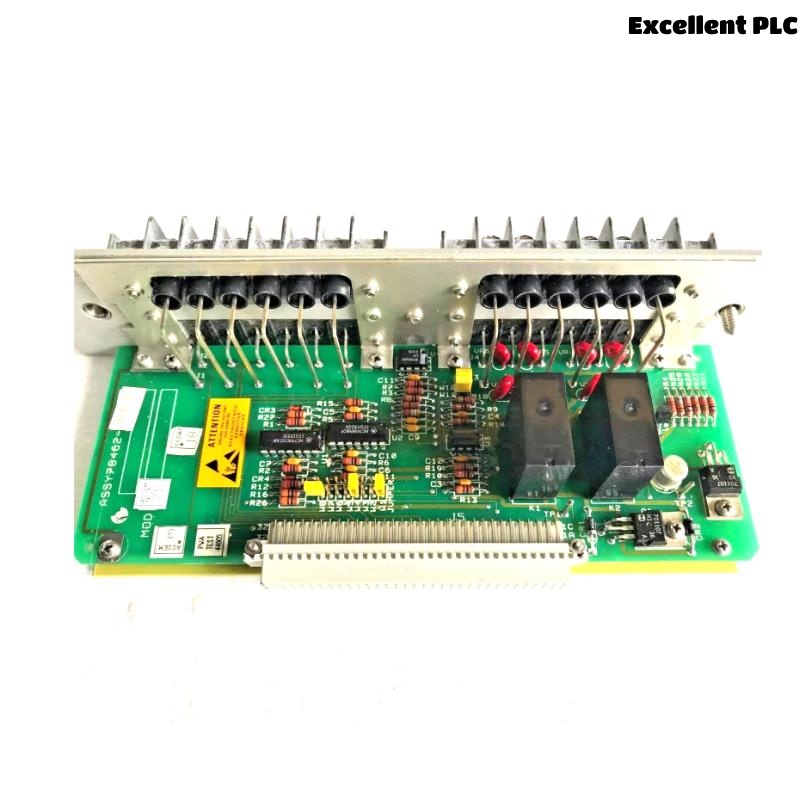

Bently Nevada 84140-01 Product Overview

The Bently Nevada 84140-01 is a high-performance proximity transducer interface module designed for industrial applications requiring reliable and accurate measurement of shaft displacement, vibration, and position. Built to operate seamlessly within Bently Nevada’s renowned vibration monitoring and machinery protection systems, the 84140-01 ensures precise data acquisition and robust signal conditioning in harsh industrial environments. Its modular design, compact size, and high compatibility make it a trusted choice for industries such as power generation, petrochemical processing, and manufacturing, where equipment reliability is critical.

Product Features and Advantages

-

High Accuracy: Offers precise displacement and vibration measurements, critical for early fault detection.

-

Robust Build: Engineered to withstand demanding conditions, including high temperatures and vibration.

-

Compact and Modular Design: Allows easy installation in control cabinets or machinery panels.

-

Wide Compatibility: Designed to integrate effortlessly with other Bently Nevada sensors and monitoring systems.

-

Long Service Life: Manufactured using durable materials to minimize maintenance and replacement cycles.

-

Trusted Brand: Backed by Bently Nevada’s decades of expertise in condition monitoring and asset protection.

Technical Specifications

| Specification | Details |

|---|---|

| Model | 84140-01 |

| Dimensions | 51x 102x 229mm |

| Weight | 0.35 kg |

| Input Voltage Range | ±24 VDC |

| Operating Temperature | -25 °C to +65 °C |

| Frequency Response | 0 – 10 kHz |

| Output Signal Type | Buffered and proportional voltage outputs |

| Mounting Method | DIN rail or panel mount |

| Material | Industrial-grade aluminum enclosure |

| Compliance | CE, RoHS, and vibration/shock certified |

| Connector Type | Screw terminal |

Applications

The Bently Nevada 84140-01 finds its place in a broad range of industries and systems:

-

Turbomachinery vibration monitoring in power plants

-

Shaft displacement measurement in compressors and pumps

-

Condition monitoring in refineries and petrochemical plants

-

Real-time machinery protection systems

-

Integration into automated predictive maintenance systems

-

Retrofitting legacy machinery for modern condition monitoring solutions

Product Advantages

-

Increases operational safety by providing accurate, real-time monitoring

-

Reduces unscheduled downtime through early detection of mechanical faults

-

Helps extend machinery life by enabling predictive maintenance strategies

-

Lowers maintenance costs by minimizing unnecessary inspections

-

Supports a wide variety of rotating equipment, making it versatile across industries

-

Engineered to maintain precision in harsh industrial environments

FAQ

Q1: What type of sensors can be connected to the Bently Nevada 84140-01?

The 84140-01 is compatible with eddy current proximity probes and other displacement sensors designed by Bently Nevada.

Q2: Is the module suitable for high-vibration environments?

Yes, it is specifically built to endure high-vibration industrial settings without compromising performance.

Q3: How is the device typically mounted?

It can be mounted either on standard DIN rails or directly onto a panel, depending on installation needs.

Q4: Can it operate outdoors?

It is primarily intended for indoor control cabinets; for outdoor use, protective enclosures are recommended.

Q5: What maintenance does it require?

Minimal maintenance; periodic inspection of wiring connections is usually sufficient.

Q6: Does it support remote monitoring?

Yes, it can transmit data to centralized monitoring systems for remote supervision.

Q7: What industries benefit most from this product?

Power generation, oil & gas, petrochemicals, and heavy manufacturing commonly use the 84140-01.

Q8: How does it contribute to predictive maintenance?

By continuously monitoring vibration and displacement, it identifies anomalies before they lead to failure.

Q9: What makes it different from other transducer interfaces?

Its robust design, proven accuracy, and integration with the Bently Nevada ecosystem set it apart.

Q10: Is the output signal configurable?

Yes, the module offers buffered and proportional voltage outputs to suit different system requirements.

Recommended Related or Same-Series Models

| Model | Description |

|---|---|

| 84141-01 | Enhanced module with extended temperature range |

| 84142-01 | Module with advanced signal conditioning features |

| 84143-01 | Compact transducer interface for limited-space installations |

| 84144-01 | High-frequency optimized proximity transducer interface |

| 84145-01 | Ruggedized version for severe environments |

| 84146-01 | Transducer interface with expanded input voltage range |

Popular Models from Bently Nevada

| Model | Key Specifications |

|---|---|

| 330101-00-12-10-02-00 | Standard proximity probe; tip diameter: 8 mm; length: 1 m |

| 330103-00-05-10-02-00 | High-temperature probe; tip diameter: 5 mm; length: 5 m |

| 3500/22M | Transient Data Interface module; supports Modbus communication |

| 3500/25 | Keyphasor module; provides reference signals for speed measurements |

| 3500/32M | 4-channel relay module; configurable relay logic |

| 3500/42M | Proximitor/seismic monitor; 4-channel vibration monitoring |

| 3500/93 | Display module; large-format LED display for system status |

| 330180-91-05 | Extension cable; armored; length: 5 m |

Excellent PLC

Excellent PLC