| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

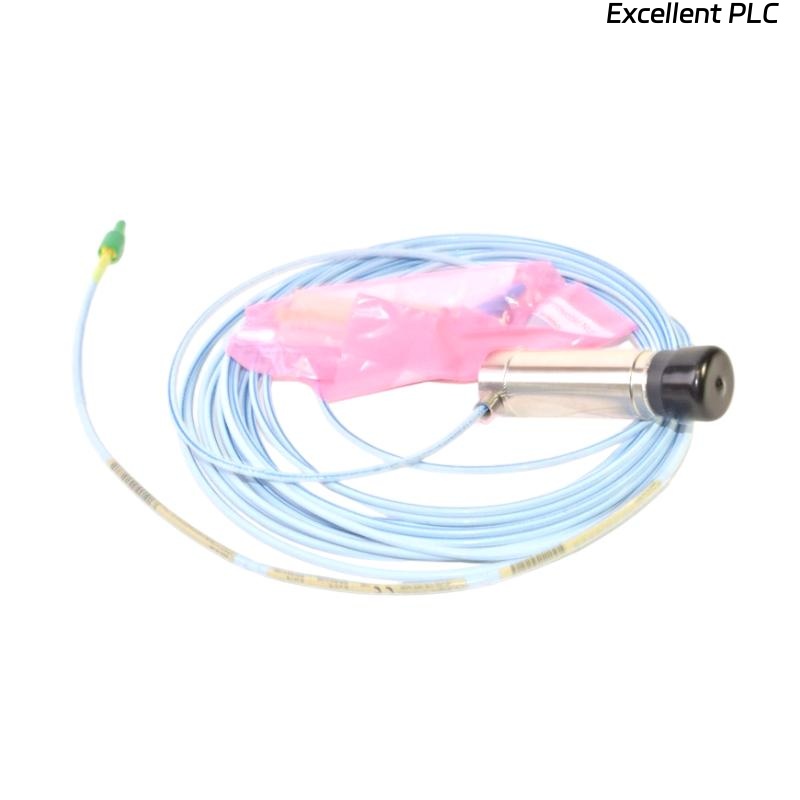

The Bently Nevada 89139-01 Standard Stud is a precision-engineered mechanical component designed to provide a secure and stable mounting solution for proximity probes, sensors, and monitoring devices in industrial machinery. It is widely used in rotating machinery applications, including turbines, compressors, pumps, and electric motors, where precise sensor alignment and stability are critical for accurate vibration and shaft displacement measurement. Constructed from high-strength stainless steel, the 89139-01 stud ensures durability and resistance to corrosion, even under harsh industrial environments. The stud’s design accommodates multiple thread types, providing versatile installation options for various Bently Nevada proximity probes and monitoring systems.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | 89139-01 |

| Type | Standard Stud |

| Diameter | 25.4 mm |

| Weight | 0.131 kg |

| Thread Types | 3/8-in-24 UNF to 1/4-in-28 UNF |

| Material | High-strength stainless steel |

| Surface Finish | Smooth, corrosion-resistant |

| Operating Temperature | –35 °C to +177 °C |

| Load Capacity | Suitable for standard probe mounting loads |

| Compliance | Compatible with Bently Nevada 3300 series probes |

| Application Category | Vibration and shaft displacement monitoring |

Applications

The 89139-01 standard stud is used in diverse industrial scenarios where secure and precise sensor mounting is required:

-

Steam and Gas Turbines – Provides stable mounting for proximity probes to monitor rotor displacement and vibration.

-

Compressors and Pumps – Ensures consistent sensor alignment for accurate monitoring of bearing wear, cavitation, and mechanical looseness.

-

Electric Motors and Generators – Maintains precise probe positioning for rotor dynamics and vibration analysis.

-

Gearboxes and Industrial Fans – Offers a reliable mounting point under high vibration and rotational stress.

-

OEM Machinery – Facilitates easy integration of sensors into custom machinery with tight space constraints.

Advantages

-

High Mechanical Stability – Maintains precise alignment for sensors, ensuring measurement accuracy.

-

Durable Construction – Stainless steel design resists corrosion, mechanical wear, and industrial contaminants.

-

Precision Manufacturing – Accurate dimensions guarantee consistent fit with multiple probe types.

-

Thread Versatility – Supports multiple thread configurations (3/8-in-24 UNF to 1/4-in-28 UNF) for flexible installation.

-

Ease of Installation – Simplifies mounting and alignment procedures for technicians.

-

Low Maintenance – Long-lasting design reduces downtime and replacement frequency.

-

Reliable in Harsh Conditions – Withstands high vibration, temperature fluctuations, and industrial exposure.

FAQ

-

What thread types does the 89139-01 support?

It supports 3/8-in-24 UNF to 1/4-in-28 UNF threads, compatible with most 3300 series probe mounts. -

What material is used in the stud?

High-strength stainless steel is used for durability and corrosion resistance. -

Can the stud handle high-vibration environments?

Yes, it is designed to maintain probe stability under typical industrial vibration conditions. -

Is this stud compatible with all 3300 NSv proximity probes?

Yes, it is designed for secure mounting of standard Bently Nevada 3300 series probes. -

Can it be used in high-temperature applications?

Yes, it operates reliably in temperatures from –35 °C to +177 °C. -

Does the stud affect the accuracy of the probe?

No, the precision manufacturing ensures stable alignment without affecting measurement accuracy. -

Is it resistant to corrosion from industrial fluids?

Yes, stainless steel construction and smooth surface finish resist corrosion and contamination. -

Can it be used for custom machinery installations?

Yes, its thread versatility allows adaptation to OEM machinery with varied mounting requirements. -

Is installation straightforward for field technicians?

Yes, the stud is designed for easy installation, alignment, and probe securing. -

Does the stud provide long-term mechanical stability?

Yes, it maintains its structural integrity over extended operational periods under industrial conditions.

Related Models in the Same Series

| Model | Description |

|---|---|

| 89139-02 | Standard stud, 25.4 mm diameter, alternate thread sizes |

| 89140-01 | High-temperature stud for NSv probe mounting |

| 89141-01 | Extended length standard stud |

| 89142-01 | Stainless steel stud with anti-vibration design |

| 89143-01 | Short-length stud for compact installations |

| 89144-01 | Threaded stud with precision alignment feature |

Popular Bently Nevada Models

| Model | Application |

|---|---|

| 330105-02-12-10-02-00 | Standard proximity probe for industrial use |

| 330400 | High-performance accelerometer for vibration detection |

| 330500 | Velocity transducer for rotating machinery |

| 330780-91-05 | Proximitor sensor for precise displacement monitoring |

| 3500/22M | Rack interface module for advanced machine monitoring |

| 3500/42M | Advanced vibration monitor with diagnostics |

Excellent PLC

Excellent PLC