| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

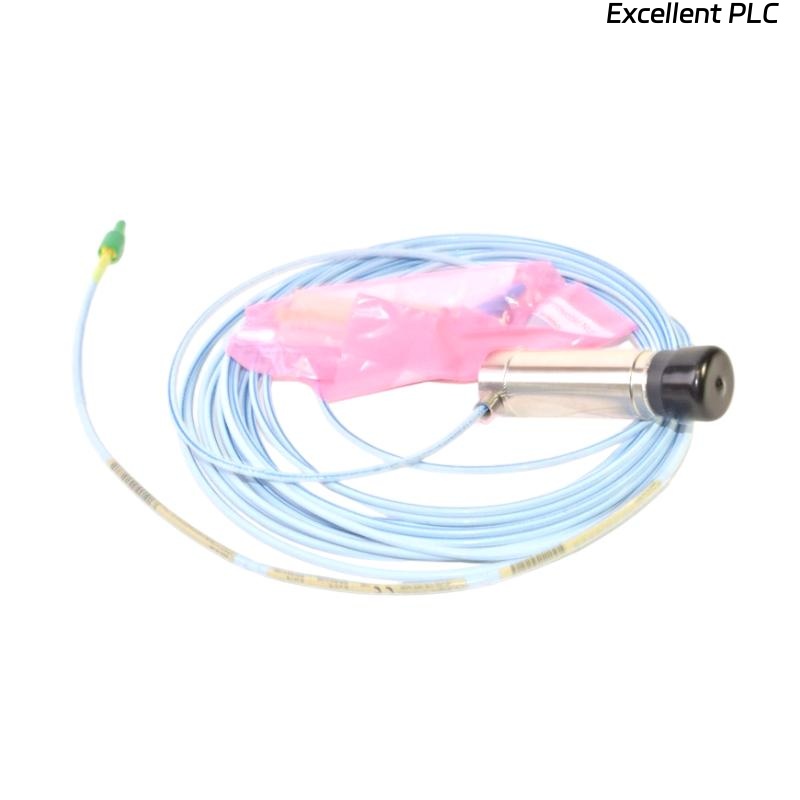

The Bently Nevada 990-05-70-03-05 Vibration Transmitter is part of the 990 series, specifically designed to provide reliable vibration monitoring and protection for rotating machinery. It converts dynamic signals from proximity probes or accelerometers into a standard 4–20 mA output, which can be easily integrated into control systems, DCS, or PLC platforms. By offering continuous vibration measurement, this transmitter enables predictive maintenance and ensures machinery operates within safe limits. It is widely used across oil & gas, petrochemical, power generation, and industrial manufacturing environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 990-05-70-03-05 |

| Series | Bently Nevada 990 Vibration Transmitter |

| Output Signal | 4–20 mA proportional to vibration |

| Input | Compatible with proximity probes and accelerometers |

| Power Supply | 18–36 VDC |

| Frequency Response | 10 Hz to 1 kHz |

| Operating Temperature | –35 °C to +85 °C |

| Enclosure | Industrial-grade, corrosion-resistant |

| Mounting Type | DIN-rail or panel mount |

| Dimensions | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

Product Applications

-

Compressors in oil & gas refineries

-

Steam turbines and gas turbines in power plants

-

Industrial pumps and blowers in chemical facilities

-

Motors, gearboxes, and rotating equipment in manufacturing plants

-

Cooling tower fans and generators

-

Any rotating machinery requiring continuous condition monitoring

Product Advantages

-

Easy Integration: Provides industry-standard 4–20 mA output for direct connection to PLC or DCS systems.

-

High Reliability: Designed for continuous operation in harsh industrial environments.

-

Predictive Maintenance: Enables early fault detection and reduces unplanned downtime.

-

Wide Compatibility: Works with a variety of proximity probes and accelerometers.

-

Compact Design: Small footprint for installation in control cabinets or near machinery.

-

Cost-Effective Monitoring: Eliminates the need for expensive standalone monitoring systems.

FAQ

Q1: What type of sensors can be connected to this transmitter?

A1: It supports both proximity probes and accelerometers for vibration measurement.

Q2: What is the output signal format?

A2: The transmitter provides a 4–20 mA signal proportional to the measured vibration.

Q3: Can this transmitter be connected directly to a PLC?

A3: Yes, it is designed to integrate with PLCs, DCS, and other control systems.

Q4: What is the frequency response range of this device?

A4: It typically supports 10 Hz to 1 kHz for accurate vibration monitoring.

Q5: Is it suitable for hazardous area applications?

A5: Some versions are available with certifications for hazardous areas, depending on the site requirements.

Q6: Does the transmitter provide real-time vibration monitoring?

A6: Yes, it continuously measures and transmits real-time vibration levels.

Q7: How does it improve machine reliability?

A7: By providing early warning signals of abnormal vibration, it helps avoid catastrophic failures.

Q8: What type of power supply is required?

A8: The transmitter operates with 18–36 VDC supply.

Q9: Can it monitor both radial and axial vibration?

A9: Yes, depending on the sensor used and installation orientation.

Q10: Is signal conditioning included in the device?

A10: Yes, the transmitter conditions and scales the sensor signal into a linear 4–20 mA output.

Recommended Same-Series or Related Models

| Model | Description |

|---|---|

| 990-05-70-02-05 | Vibration transmitter with similar functions but different scaling option |

| 990-05-70-01-IN | Industrial variant optimized for integration |

| 990-05-50-03-00 | Alternate version with modified input compatibility |

| 990-04-70-01-007 | Compact transmitter version for specific machinery |

| 990-04-50-01-CN | Chinese market variant with identical functionality |

| 990-05-70-03-00 | Closely related model with slight calibration differences |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 3300 XL Proximitor | Widely used proximity transducer system |

| 3500/22M | Machine monitoring system module |

| 330103 | Standard proximity probe |

| 3500/42M | Vibration monitoring module |

| 330400 | Accelerometer for machinery vibration |

| 3701/55 | Machinery protection system |

| 3500/32M | Relay module for protective shutdown |

| 330104 | Extension cable for probe system |

Excellent PLC

Excellent PLC