| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

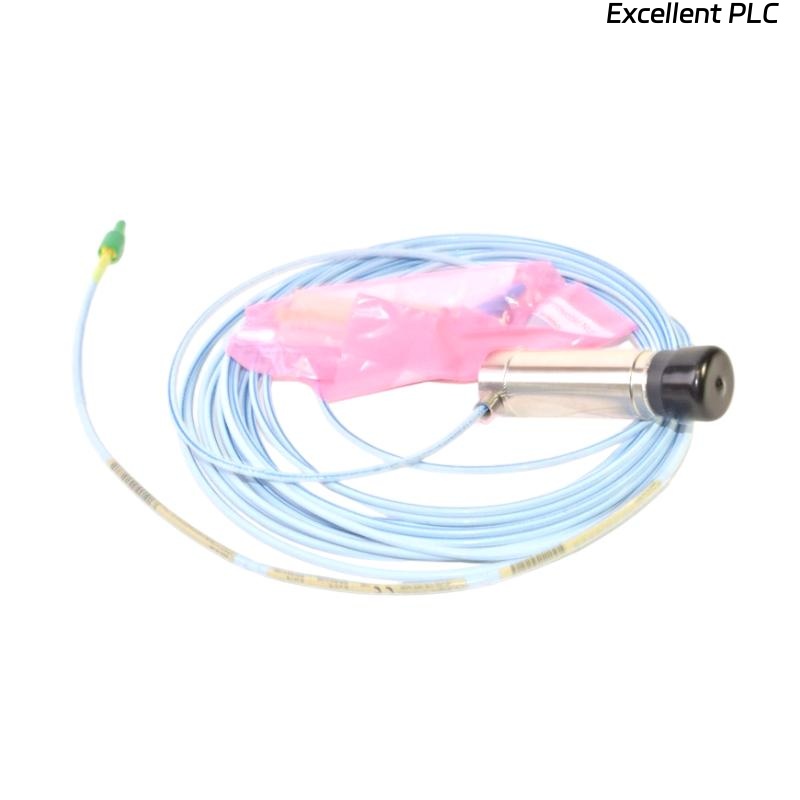

The Bently Nevada 990-05-XX-02-00 MOD: 147202-01 Vibration Transmitter is a precision measurement instrument designed to accurately convert vibration data from proximity probes into standardized electrical output signals. This transmitter is an essential part of vibration monitoring systems used in industries such as power generation, oil and gas, petrochemical, and manufacturing, ensuring that machinery operates efficiently and within safe limits.

The 990 Vibration Transmitter transforms vibration measurements into either 4-20 mA or 0-10 VDC signals, providing critical real-time data to monitoring systems. With its compact design and flexible integration options, this device plays a key role in predictive maintenance by allowing for early fault detection, thus reducing unplanned downtime and extending the life of critical equipment.

For more information or assistance, please contact our customer service team.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model | 990-05-XX-02-00 MOD: 147202-01 |

| Dimensions (L x W x H) | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Input | Vibration signals from proximity probes |

| Output | 4-20 mA or 0-10 VDC (selectable) |

| Power Supply | 24 VDC ±20% |

| Operating Temperature | -40°C to +85°C |

| Vibration Range | 0 to 10 g (adjustable) |

| Signal Conditioning | Built-in filtering and amplification |

| Mounting Type | DIN rail or panel mount |

| Compliance | CE, UL Certified |

Applications

The 990-05-XX-02-00 MOD: 147202-01 Vibration Transmitter is ideal for a wide range of applications where continuous and accurate vibration monitoring is critical for maintaining equipment health and ensuring smooth operations. Key applications include:

-

Condition Monitoring: Continuous vibration monitoring of critical rotating machinery, such as turbines, compressors, and motors, to detect early signs of wear, imbalance, or misalignment.

-

Power Generation: Ensures the safe and reliable operation of power plants by monitoring turbines, generators, and other vital equipment for excessive vibration, which could signal potential failures.

-

Oil & Gas: Used to monitor pumps, compressors, and motors in the oil and gas industry, providing early warning signals to prevent catastrophic failures and unplanned downtime.

-

Petrochemical: Vital for ensuring the operational integrity of pumps, motors, and compressors in petrochemical facilities, enabling the early detection of vibration anomalies.

-

Manufacturing: Helps in monitoring production machinery, such as conveyor belts and industrial machines, reducing the risk of production delays caused by mechanical failures.

-

Industrial Automation: Integrates seamlessly into automated control systems, providing real-time vibration data to improve system performance and reduce risk.

Advantages

-

Wide Vibration Range: The transmitter is adjustable from 0 to 10 g, providing versatility for monitoring a wide range of machinery from small motors to large turbines.

-

High Accuracy: With integrated signal conditioning and amplification, the 990-05-XX-02-00 MOD: 147202-01 provides precise and reliable vibration data, enabling accurate fault detection.

-

Flexible Output Options: Offers both 4-20 mA and 0-10 VDC output signals, ensuring compatibility with a variety of monitoring systems and control devices.

-

Durability: Built to withstand harsh industrial environments, the transmitter operates in temperatures ranging from -40°C to +85°C, making it ideal for challenging conditions.

-

Easy Integration: The compact size and flexible mounting options (DIN rail or panel mount) allow for straightforward installation and integration into existing monitoring systems.

-

Preventive Maintenance: By providing early detection of abnormal vibration patterns, the transmitter helps prevent equipment failures, reducing maintenance costs and downtime.

-

Cost-Effective: The ability to predict equipment failure allows for optimized maintenance schedules and reduced emergency repairs, resulting in long-term cost savings.

FAQ

-

What output signal does the 990-05-XX-02-00 MOD: 147202-01 provide?

-

The transmitter provides selectable output options of 4-20 mA or 0-10 VDC to suit different system requirements.

-

-

What type of input does the vibration transmitter accept?

-

The device accepts vibration signals from proximity probes, typically used to measure the vibration levels of rotating machinery.

-

-

What is the vibration range of the 990-05-XX-02-00?

-

The transmitter offers an adjustable vibration range from 0 to 10 g, making it suitable for a variety of equipment.

-

-

What is the power supply requirement for the 990-05-XX-02-00 MOD: 147202-01?

-

The transmitter requires a 24 VDC power supply, with a tolerance of ±20%.

-

-

How does the 990-05-XX-02-00 transmitter help with predictive maintenance?

-

By continuously monitoring vibrations and detecting anomalies, the transmitter allows for early detection of faults, enabling predictive maintenance and reducing unplanned downtime.

-

-

What is the operating temperature range of the 990-05-XX-02-00?

-

The transmitter operates in an environmental temperature range from -40°C to +85°C, making it suitable for harsh industrial environments.

-

-

How is the 990-05-XX-02-00 transmitter mounted?

-

The transmitter can be mounted either on a DIN rail or directly onto a panel, providing flexibility in installation.

-

-

What industries benefit from using the 990-05-XX-02-00 MOD: 147202-01 vibration transmitter?

-

This transmitter is ideal for industries such as power generation, oil & gas, petrochemical, manufacturing, and industrial automation.

-

-

Does the 990-05-XX-02-00 comply with safety and quality standards?

-

Yes, it is CE and UL certified, ensuring it meets international safety and quality standards for use in industrial applications.

-

-

Can the 990-05-XX-02-00 be used for machinery with varying sizes and types?

-

Yes, the transmitter’s adjustable vibration range (0 to 10 g) allows it to be used for monitoring machinery of various sizes, from small motors to large turbines.

Related Models

| Model | Description |

|---|---|

| 990-05-XX-02-01 | Enhanced vibration transmitter with wider vibration range |

| 990-05-XX-03-00 | Vibration transmitter with dual output channels for advanced control |

| 990-05-XX-02-01 | Vibration transmitter with improved signal conditioning |

| 990-05-XX-04-00 | Vibration transmitter with integrated diagnostics |

| 990-05-XX-02-02 | Compact vibration transmitter with extended temperature range |

| 990-05-XX-02-03 | Vibration transmitter with network communication capabilities |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 3500/20-01-03 | High-precision vibration sensor for machinery monitoring |

| 3500/32-02-01 | Accelerometer for advanced vibration monitoring |

| 3300/22-01-01 | Tachometer for precise speed measurements |

| 3500/90-01-04 | Transducer interface for signal conversion |

| 3500/42-01-03 | Control module for protective equipment systems |

| 3500/20-01-01 | Vibration monitoring system for rotating machinery |

Excellent PLC

Excellent PLC