| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

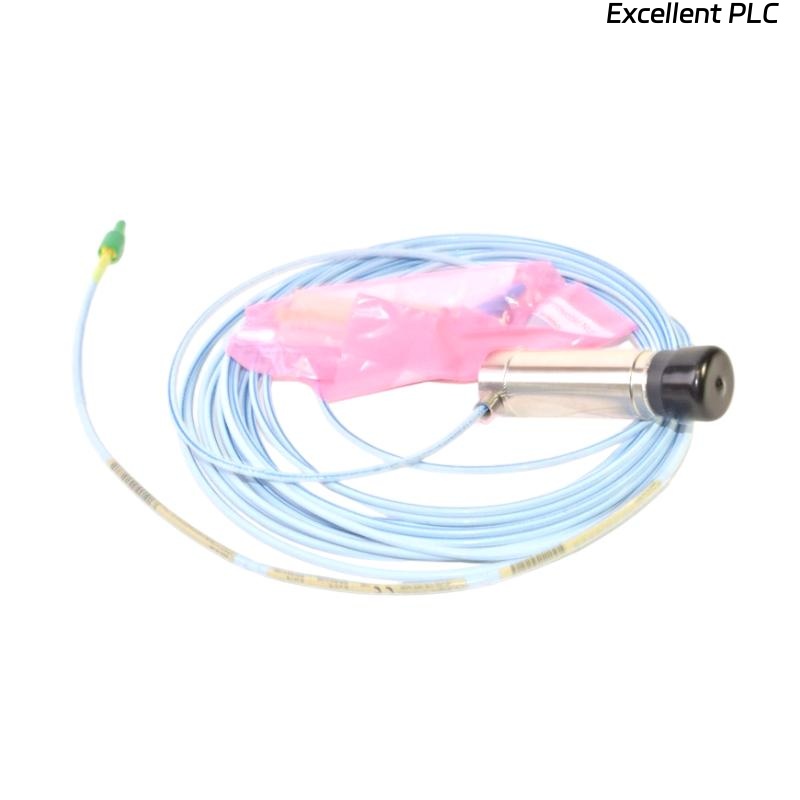

The Bently Nevada 990-05-XX-03 990 Vibration Transmitter is a high-reliability industrial device designed to continuously monitor and transmit critical vibration data from rotating machinery. Manufactured by Bently Nevada, a global leader in condition monitoring and machinery protection systems, this transmitter provides real-time vibration measurement, allowing early detection of mechanical faults such as misalignment, imbalance, bearing wear, or looseness.

The 990-05-XX-03 model is part of the trusted 990 Series, known for its robust design, precision measurement, and ease of integration into industrial control systems. With standard 4–20 mA output, this transmitter simplifies the connection to PLCs, DCS, or SCADA platforms, making it an essential component for predictive maintenance strategies in industries such as oil & gas, petrochemicals, power generation, and manufacturing.

Key Features

-

Continuous Vibration Monitoring: Real-time tracking of machinery health to avoid unexpected failures.

-

Standard 4–20 mA Output: Industry-recognized output signal for simple integration with existing control systems.

-

Rugged Industrial Design: Built to withstand demanding environments including extreme temperatures and harsh conditions.

-

Enhanced Environmental Protection: Additional sealing for corrosive, humid, or hazardous industrial settings.

-

Compact and Lightweight: Space-saving design allows easy installation on various equipment.

-

Broad Probe Compatibility: Supports Bently Nevada proximity probes, including 3300 XL series.

-

Accurate Fault Detection: Identifies early-stage faults such as imbalance, bearing defects, or shaft misalignment.

-

Explosion-Proof Variants Available: Suitable for hazardous area applications in oil & gas and petrochemical sectors.

-

Factory-Calibrated for Accuracy: Ensures reliable performance with minimal setup requirements.

-

Global Compliance: CE, CSA, ATEX certified options available for international use.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | 990-05-XX-03 |

| Product Type | Vibration Transmitter |

| Measurement Technology | Non-contact proximity probe system |

| Output Signal | 4–20 mA DC proportional to vibration amplitude |

| Measurement Range | Typically 0–200 μm (0–8 mils), configurable |

| Power Supply | Loop-powered, 12 to 35 VDC |

| Frequency Response | 2 Hz to 10 kHz |

| Probe Compatibility | Compatible with Bently Nevada 3300 XL and other series |

| Environmental Protection | IP66, enhanced sealing for corrosive or harsh conditions |

| Housing Material | Stainless Steel, corrosion-resistant |

| Operating Temperature Range | -35°C to +85°C |

| Certifications | CE, RoHS, CSA, ATEX options available |

| Dimensions | 100.1 x 73.9 x 53.3mm |

| Weight | 0.43 kg |

| Mounting | Threaded installation, 1/4-28 UNF or M8 standard |

Industry Applications

-

Oil & Gas: Protects pumps, compressors, and turbines from vibration-related failures in upstream and downstream operations.

-

Petrochemical Processing: Monitors rotating equipment in chemical plants to prevent costly downtime.

-

Power Generation: Ensures reliable operation of generators, turbines, and auxiliary rotating machinery.

-

Mining and Metals: Vibration detection on crushers, conveyors, and material handling equipment.

-

Water and Wastewater Treatment: Monitors pump and motor health to reduce service interruptions.

-

Pulp & Paper Industry: Prevents breakdowns of critical equipment such as refiners, pumps, and paper machines.

-

General Manufacturing: Applied to motors, fans, and other rotating machinery across multiple production environments.

Product Advantages

-

Early Fault Detection: Identifies developing mechanical problems before they lead to equipment damage.

-

Simplified System Integration: Standard 4–20 mA output easily connects to existing PLC, DCS, or SCADA systems.

-

Durability in Harsh Environments: Enhanced environmental sealing protects against moisture, dust, and chemicals.

-

Compact, Flexible Installation: Fits into space-limited machine setups with minimal installation effort.

-

Reduces Maintenance Costs: Predictive monitoring helps plan maintenance and avoid costly repairs.

-

Versatile Compatibility: Works with multiple probe types to suit different applications.

-

Explosion-Proof Options: Available for hazardous area installations with ATEX or CSA certifications.

-

Fast, Accurate Data: Provides precise vibration measurements in real-time, enabling rapid response.

-

Reliable Long-Term Operation: Built with industrial-grade materials for extended service life.

-

Proven Brand Performance: Developed by Bently Nevada, a trusted name in vibration and condition monitoring.

Frequently Asked Questions (FAQ)

-

What does the 990-05-XX-03 Vibration Transmitter measure?

It measures the vibration levels of rotating machinery, providing a proportional 4–20 mA output. -

What distinguishes the -03 model from other 990 transmitters?

The 990-05-XX-03 model features enhanced environmental sealing, making it suitable for corrosive or harsh environments. -

Which proximity probes are compatible with this transmitter?

It is compatible with Bently Nevada 3300 XL series and other standard proximity probes. -

What is the typical measurement range?

Standard range is 0–200 μm (0–8 mils), with custom configurations available upon request. -

Can the transmitter be used in hazardous areas?

Yes, explosion-proof and hazardous area-certified versions are available. -

How is the 990-05-XX-03 powered?

It operates as a loop-powered device, requiring 12 to 35 VDC from the connected control system. -

What is the output signal format?

A standard 4–20 mA current loop signal, commonly used in industrial automation systems. -

Where is the transmitter commonly installed?

Directly on or near rotating machinery such as pumps, motors, compressors, and turbines. -

Does the transmitter require regular calibration?

It is factory-calibrated, but periodic field verification is recommended to maintain accuracy. -

How does it help prevent equipment failures?

By providing continuous vibration monitoring, it enables early detection of developing mechanical issues.

Related Models

| Model | Description |

|---|---|

| 990-05-XX-01 | Standard 990 vibration transmitter for general machinery monitoring. |

| 990-05-XX-00 | Entry-level 990 series transmitter for basic applications. |

| 990-06-XX-01 | Extended range vibration transmitter for heavy-duty equipment. |

| 990-05-XX-02 | Model with modified output scaling for specific process requirements. |

| 990-07-XX-01 | High-sensitivity transmitter for low-vibration environments. |

| 990-08-XX-01 | Advanced transmitter with integrated diagnostics and fault detection. |

Popular Bently Nevada Models

| Model | Description |

|---|---|

| 330101-00-14-10-02-05 | 3300 XL 8 mm Proximity Probe for precise vibration measurements. |

| 330130-045-00-05 | 3300 XL Standard Extension Cable for proximity monitoring setups. |

| 330180-91-05 | Velomitor Piezoelectric Velocity Sensor for overall machinery condition monitoring. |

| 3500/15-05-05-00 | 3500 Series Power Supply for vibration monitoring systems. |

| 3500/22M-01-01-00 | 3500 System Transient Data Interface Module. |

| 330104-00-09-10-02-00 | 3300 XL Reverse Mount Proximity Probe for compact installations. |

Excellent PLC

Excellent PLC