| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

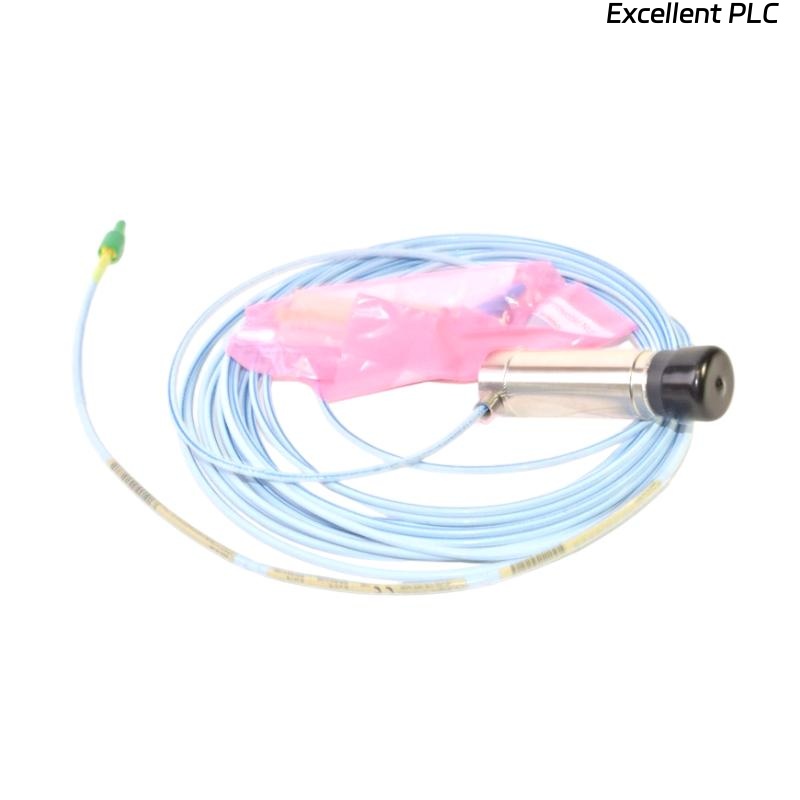

The Bently Nevada 990-10-XX-01-RU (MOD: 163930-01) is a vibration transmitter designed for continuous monitoring of machinery in industrial environments. This model is part of Bently Nevada’s 990 series, known for high reliability and precision in vibration monitoring. The 990-10-XX-01-RU converts signals from vibration sensors like accelerometers or proximity probes into actionable data, which is outputted as analog (4-20 mA) or digital (Modbus) signals. This versatility makes it ideal for integration into a wide variety of machinery monitoring and predictive maintenance systems.

The 990-10-XX-01-RU vibration transmitter is designed to detect imbalances, misalignments, and bearing wear, which helps prevent machinery failure. By providing early warnings about mechanical issues, the transmitter allows operators to take corrective action before equipment failure occurs, reducing downtime and maintenance costs.

Product Parameters

| Parameter | Specification |

|---|---|

| Model | Bently Nevada 990-10-XX-01-RU (MOD: 163930-01) |

| Sensor Input | Vibration sensor input (accelerometer, proximity probe) |

| Output Signal | Analog (4-20 mA) or Digital (Modbus) |

| Dimensions (L x W x H) | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Operating Voltage | 18-30 VDC |

| Response Time | 1 ms (typical) |

| Operating Temperature | -40°C to +85°C |

| Protection Rating | IP66 |

Product Applications

The Bently Nevada 990-10-XX-01-RU vibration transmitter is suitable for a wide range of industrial applications, including:

-

Rotating Equipment: Ideal for monitoring the health of rotating machinery such as motors, pumps, compressors, turbines, and fans.

-

Power Generation: Used in power plants to monitor equipment such as generators and pumps, ensuring smooth and efficient operations.

-

Oil & Gas: Essential for monitoring critical equipment such as pumps and compressors in harsh and remote environments.

-

Manufacturing: Provides vibration data for milling machines, conveyors, and other manufacturing machinery, preventing costly downtime.

-

Mining: Monitors heavy-duty equipment like crushers, grinders, and drills, minimizing the risk of failure in demanding environments.

Product Advantages

-

Accurate Vibration Monitoring: The 990-10-XX-01-RU provides accurate and reliable vibration measurements, helping detect faults like misalignment, imbalances, and bearing wear at an early stage.

-

Flexible Output Options: With analog (4-20 mA) and digital (Modbus) outputs, it can easily integrate with a variety of control and monitoring systems, providing flexibility for different setups.

-

Real-Time Data: Continuous monitoring provides real-time feedback, allowing operators to make informed decisions and take corrective actions immediately.

-

Compact and Lightweight: The 990-10-XX-01-RU is designed with a compact form factor (100.1 x 73.9 x 53.3 mm) and weighs just 0.43 kg, making it easy to install in tight spaces.

-

Durability: It has an IP66 protection rating, which means it is dustproof and water-resistant, capable of operating reliably in harsh industrial conditions.

-

Wide Operating Temperature Range: The device operates in temperatures ranging from -40°C to +85°C, making it suitable for both hot and cold environments.

-

Fast Response Time: With a 1 ms response time, it is capable of monitoring high-speed machinery and providing immediate feedback.

FAQ

-

What sensors can be used with the 990-10-XX-01-RU?

-

This vibration transmitter is compatible with accelerometers and proximity probes to measure machinery vibration.

-

-

What output options are available for this model?

-

The 990-10-XX-01-RU provides both analog (4-20 mA) and digital (Modbus) outputs, allowing integration with a variety of monitoring systems.

-

-

How does this device help prevent machinery failure?

-

By continuously monitoring vibration, the 990-10-XX-01-RU detects issues like imbalances or misalignments early, which helps prevent costly breakdowns.

-

-

What types of equipment can be monitored with this transmitter?

-

It is ideal for monitoring a wide range of equipment, including pumps, fans, turbines, and compressors.

-

-

Can the 990-10-XX-01-RU integrate with existing systems?

-

Yes, it can easily be integrated into existing control systems and monitoring setups with its analog and digital output options.

-

-

What is the response time of the 990-10-XX-01-RU?

-

The 990-10-XX-01-RU has a 1 ms response time, which allows for real-time data and quick detection of potential issues.

-

-

What industries use the 990-10-XX-01-RU?

-

It is used in industries such as oil & gas, power generation, mining, and manufacturing for monitoring critical machinery.

-

-

What protection rating does the 990-10-XX-01-RU have?

-

The 990-10-XX-01-RU has an IP66 protection rating, which means it is dustproof and water-resistant, suitable for harsh environments.

-

-

What is the operating temperature range of the 990-10-XX-01-RU?

-

This transmitter operates in temperatures ranging from -40°C to +85°C, making it suitable for both hot and cold conditions.

-

-

How accurate are the vibration measurements?

-

The 990-10-XX-01-RU provides high-accuracy vibration data, allowing for the early detection of mechanical issues and ensuring efficient machinery monitoring.

-

Related Models from the Same Series

| Model | Description |

|---|---|

| 990-10-70-01-00 | Analog and digital output for comprehensive vibration monitoring. |

| 990-10-70-02-00 | Compact version with analog output for basic applications. |

| 990-10-70-03-00 | High-frequency version designed for rotating machinery. |

| 990-10-70-04-00 | Includes remote monitoring capabilities with wireless communication. |

| 990-10-70-05-00 | Dual input channels for monitoring multiple vibration sources simultaneously. |

| 990-10-70-06-00 | Heavy-duty version for industrial environments with high vibration conditions. |

Popular Models from Bently Nevada

| Model | Description |

|---|---|

| 330930-040-01-05 | Vibration monitoring system designed for critical machinery with high-frequency detection and digital output. |

| 330930-045-05-00 | Multi-input vibration sensor with real-time diagnostics and analog output, ideal for large-scale industrial applications. |

| 330930-050-01-01 | Compact vibration transmitter designed for smaller machines, offering digital (Modbus) and analog (4-20 mA) outputs. |

| 330930-060-02-01 | Heavy-duty vibration monitoring system with dual input channels for monitoring multiple machines simultaneously. |

| 330930-030-03-05 | Advanced vibration sensor with wireless capabilities for remote monitoring in industrial environments. |

| 330930-070-04-00 | High-precision vibration monitoring system designed for turbines and generators, offering analog and digital outputs. |

Excellent PLC

Excellent PLC