| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Overview

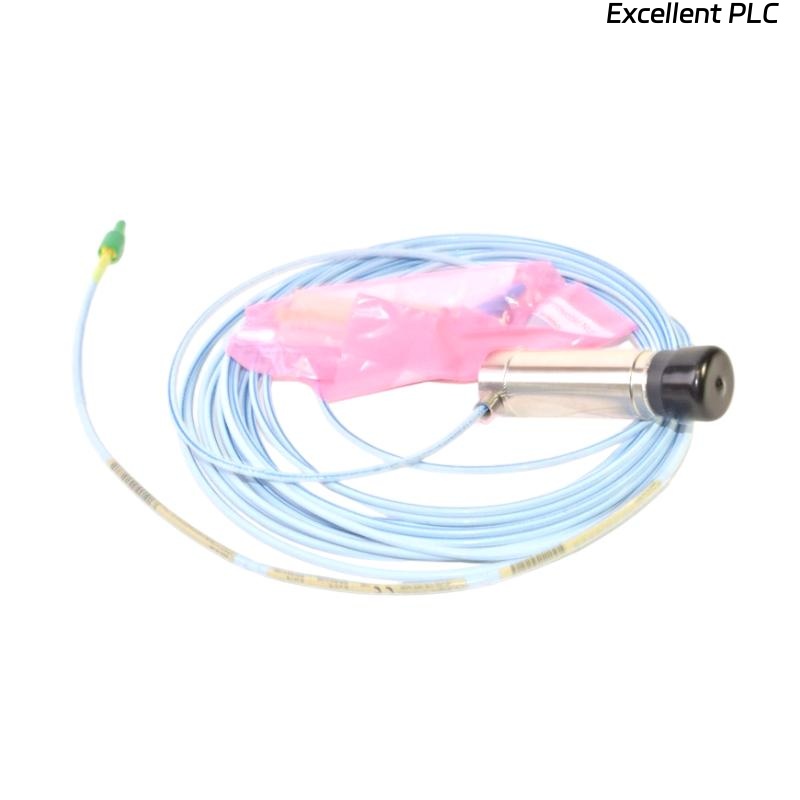

The Bently Nevada 990-10-XX-02-00 is a high-performance vibration transmitter designed for real-time monitoring of rotating machinery. It converts raw vibration signals into precise, continuous outputs that can be used by control systems to detect imbalance, misalignment, bearing faults, and other mechanical issues.

Key Features

-

Provides continuous vibration measurement for rotating machinery

-

Compatible with Bently Nevada 990 monitoring systems

-

High accuracy and stable performance over time

-

Rugged design for harsh industrial conditions

-

Supports predictive maintenance and machinery protection

-

Easy integration with existing monitoring infrastructure

-

Configurable output for voltage or current signals

Technical Specifications

| Item | Specification |

|---|---|

| Model Number | 990-10-XX-02-00 |

| Series | 990 |

| Type | Vibration Transmitter |

| Measurement Range | Configurable per system requirements |

| Output | Voltage or current (depending on monitoring system) |

| Case Material | Stainless Steel or Industrial-grade enclosure |

| Operating Temperature | -40 °C to +120 °C |

| Storage Temperature | -50 °C to +125 °C |

| Humidity | Up to 100% condensing |

| Mounting | Threaded or flange mount |

| Dimensions | 100.1 x 73.9 x 53.3 mm |

| Weight | 0.43 kg |

| Compliance | CE, RoHS |

Industry Applications

-

Power Generation – turbine and generator vibration monitoring

-

Oil & Gas – pumps, compressors, and rotating equipment monitoring

-

Petrochemical & Chemical – machinery protection for critical equipment

-

Industrial Manufacturing – monitoring high-speed rotating machinery

-

Water & Wastewater – pump and motor vibration protection

Advantages

-

Provides precise vibration measurement to detect early signs of equipment faults

-

Rugged and durable for harsh industrial environments

-

Seamless integration with Bently Nevada 990 monitoring systems

-

Supports predictive maintenance to reduce unplanned downtime

-

Enhances machinery protection and operational safety

-

Reliable long-term performance under variable operating conditions

Frequently Asked Questions (FAQ)

Q1: What is the primary function of this transmitter?

It continuously measures machinery vibration to support predictive maintenance and fault detection.

Q2: Which monitoring systems is it compatible with?

Bently Nevada 990 monitoring systems.

Q3: What is the measurement range?

Configurable depending on system requirements.

Q4: What output types are supported?

Voltage or current outputs, depending on the monitoring system.

Q5: What is the operating temperature range?

-40 °C to +120 °C.

Q6: Can it operate in high humidity conditions?

Yes, it is rated for up to 100% condensing humidity.

Q7: What material is the transmitter enclosure made of?

Stainless steel or equivalent industrial-grade material.

Q8: How is it mounted?

Threaded or flange mounting.

Q9: Is it suitable for harsh industrial environments?

Yes, it is designed for rugged conditions.

Q10: Which industries commonly use this transmitter?

Power Generation, Oil & Gas, Petrochemical, Industrial Manufacturing, and Water & Wastewater.

Related Bently Nevada Modules

| Model Number | Description |

|---|---|

| 990-10-XX-02-01 | 990 Vibration Transmitter |

| 990-10-XX-03-00 | 990 Vibration Transmitter |

| 3500/42M | Proximitor®/Seismic Monitoring Module |

| 3500/50 | Tachometer Module |

| 3500/92 | Communication Gateway Module |

| 330500-02-05 | Velomitor Piezoelectric Velocity Sensor |

Popular Bently Nevada Modules

| Model Number | Description |

|---|---|

| 990-10-XX-02-00 | 990 Vibration Transmitter |

| 990-10-XX-02-01 | 990 Vibration Transmitter |

| 990-10-XX-03-00 | 990 Vibration Transmitter |

| 3500/42M | Proximitor®/Seismic Monitoring Module |

| 3500/50 | Tachometer Module |

| 3500/92 | Communication Gateway Module |

Excellent PLC

Excellent PLC