| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

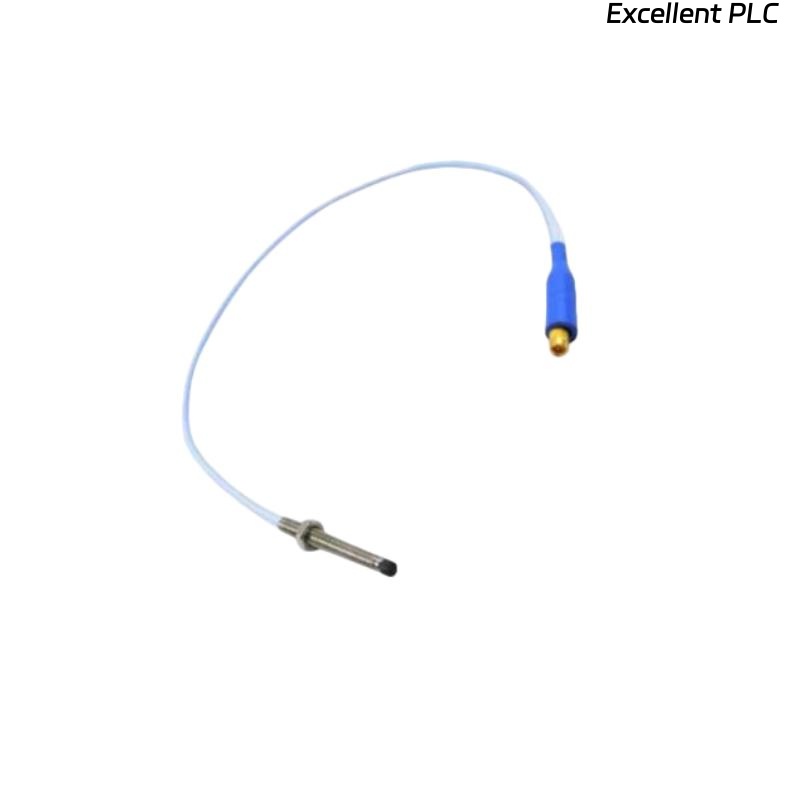

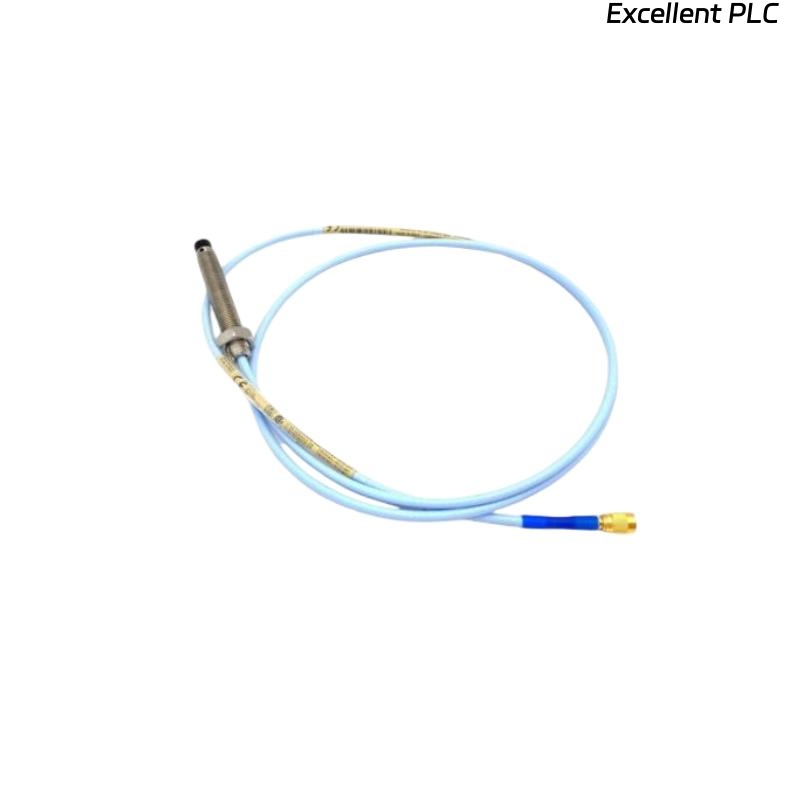

The Bently Nevada AAP1407030-00100 3300 XL NSv Eddy Current Probe is a high-precision sensor designed to provide accurate, non-contact displacement and vibration measurements in rotating machinery applications. Part of the 3300 XL series, the AAP1407030-00100 is optimized for use in demanding environments where reliability, accuracy, and continuous monitoring of critical assets are required. It is commonly used in industries such as power generation, oil and gas, and heavy machinery to monitor equipment health and detect early signs of potential failures.

This eddy current probe works by generating an electromagnetic field and measuring changes in the field caused by the presence and movement of conductive materials. By detecting the displacement of machine components such as shafts and rotors, the probe provides essential data for condition monitoring and predictive maintenance programs.

The AAP1407030-00100 probe offers superior measurement accuracy, long-term stability, and low-maintenance operation, making it an ideal choice for real-time monitoring of vital machinery components in industries where downtime is costly.

Parameters

| Parameter | Description |

|---|---|

| Model | AAP1407030-00100 |

| Probe Type | Eddy Current Probe |

| Packaging Dimensions | 200 x 150 x 100 mm |

| Packaging Weight | 2 kg |

| Measurement Range | Up to 50 mm (depending on target) |

| Output Signal | 4-20 mA |

| Supply Voltage | 18-30 V DC |

| Frequency Response | Up to 1 MHz |

| Operating Temperature | -40°C to +85°C |

| Housing Material | Stainless Steel |

| Connector Type | 4-pin industrial connector |

Applications

The Bently Nevada AAP1407030-00100 eddy current probe is designed for high-precision, non-contact measurement in several critical applications, particularly in the monitoring of rotating machinery:

-

Rotating Machinery Monitoring: Used extensively for monitoring the displacement and vibration of rotating components such as shafts, turbines, and motors. By providing continuous data, the sensor helps to identify early warning signs of misalignment, wear, or rotor imbalance.

-

Condition Monitoring in Industrial Equipment: Ideal for monitoring the health of key components in industrial machinery, including compressors, generators, and pumps. The sensor helps detect issues like bearing wear or shaft misalignment, preventing costly failures.

-

Predictive Maintenance: This probe supports predictive maintenance programs by providing real-time data that can be used to schedule maintenance activities before critical failures occur, reducing downtime and increasing asset lifespan.

-

Power Generation: Commonly used in power plants to monitor turbines, compressors, and generators. The sensor helps to prevent equipment failures by providing early detection of performance issues, ensuring that critical machinery runs efficiently.

-

Vibration and Displacement Measurement: The probe is used to monitor vibrations and displacements in rotating machinery, providing vital information on equipment health and performance, helping to prevent operational interruptions.

Advantages

-

Non-contact Measurement: The AAP1407030-00100 operates on the principle of eddy current technology, which allows for non-contact measurement of vibration and displacement. This results in lower maintenance requirements and longer lifespan for both the probe and machinery components.

-

High Sensitivity and Accuracy: Designed for high-precision applications, the probe offers outstanding accuracy, making it capable of detecting even the smallest displacement or vibration changes in machinery components.

-

Durability and Robustness: With its stainless steel housing, the probe is designed to withstand harsh industrial environments, including exposure to high temperatures, moisture, dust, and vibrations. It is built to provide long-term reliability in even the most challenging conditions.

-

Wide Temperature Range: The probe can operate in a broad temperature range from -40°C to +85°C, making it suitable for use in a variety of environments, including both extreme heat and cold.

-

Real-time Monitoring for Predictive Maintenance: Continuous real-time data provides valuable insights into machinery health, enabling operators to make data-driven decisions and take action before failures occur, improving asset reliability and minimizing unplanned downtime.

-

Easy Integration: The AAP1407030-00100 probe is designed with a standard 4-20 mA output, making it easily integrable into most industrial control and monitoring systems for seamless data collection and processing.

FAQ

1. How does the Bently Nevada AAP1407030-00100 eddy current probe work?

The probe uses electromagnetic induction to generate eddy currents in the target material. The sensor detects variations in these currents caused by the displacement or vibration of the target, which it then converts into a corresponding measurement.

2. What is the measurement range of the AAP1407030-00100 probe?

The probe can measure displacements and vibrations up to 50 mm, depending on the target material and installation setup.

3. Can the probe be used for monitoring rotating machinery?

Yes, the AAP1407030-00100 is ideal for monitoring rotating machinery, such as turbines, motors, and pumps, where it detects displacement, vibration, and misalignment in critical components.

4. What type of output signal does the sensor provide?

The probe provides a 4-20 mA output signal, which is commonly used in industrial applications for continuous monitoring and integration with control systems.

5. What industries typically use this eddy current probe?

Industries such as power generation, oil and gas, manufacturing, and heavy machinery use the AAP1407030-00100 probe for machinery health monitoring and predictive maintenance.

6. How is the probe mounted on machinery?

The probe can be surface-mounted or threaded into the machinery, providing flexible installation options for a variety of applications.

7. What is the temperature range of the AAP1407030-00100?

The probe can operate in temperatures from -40°C to +85°C, making it suitable for both cold and hot environments.

8. Can the sensor withstand harsh environmental conditions?

Yes, the sensor is housed in stainless steel, making it resistant to dust, moisture, and mechanical stresses. It is designed to operate reliably in challenging industrial conditions.

9. How does this sensor help in predictive maintenance?

By providing real-time data on displacement and vibration, the probe helps detect early signs of equipment issues, allowing operators to schedule maintenance before failures occur, reducing downtime and extending the lifespan of machinery.

10. How does the AAP1407030-00100 compare to other probes in the 3300 XL series?

The AAP1407030-00100 offers similar high accuracy and reliability as other probes in the 3300 XL series but is specifically optimized for use in environments where high precision and low maintenance are required.

Recommended Related Models

| Model | Description |

|---|---|

| AAP1407030-00200 | Similar eddy current probe for higher displacement ranges and higher frequency applications. |

| AAP1407030-00300 | Compact model designed for applications with space constraints or short-range measurements. |

| AAP1407030-00400 | Proximity probe with extended temperature range for use in high-temperature environments. |

| AAP1407030-00500 | High-precision model optimized for vibration measurement in critical rotating machinery. |

| AAP1407030-00600 | Versatile model offering enhanced sensitivity for small displacement measurement in fine-tuned applications. |

| AAP1407030-00700 | Robust probe designed for use in extreme environments with high vibration and noise levels. |

Popular Models

| Model | Description |

|---|---|

| AAP1407030-00100 | High-precision sensor for rotating machinery monitoring in industries like power generation and oil & gas. |

| 330980-060-00-05 | Proximity sensor optimized for real-time monitoring of large-scale industrial equipment. |

| 330980-060-00-03 | Compact eddy current sensor designed for short-range measurements and high-speed machinery applications. |

| 330980-060-00-06 | Enhanced version of the 3300 XL sensor for use in challenging conditions with increased durability. |

| 330980-060-00-07 | Precision proximity sensor with extended measurement range for large machinery monitoring. |

| 330980-060-00-11 | Advanced sensor designed for highly sensitive vibration measurement and monitoring of large rotating machinery. |

Excellent PLC

Excellent PLC