| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

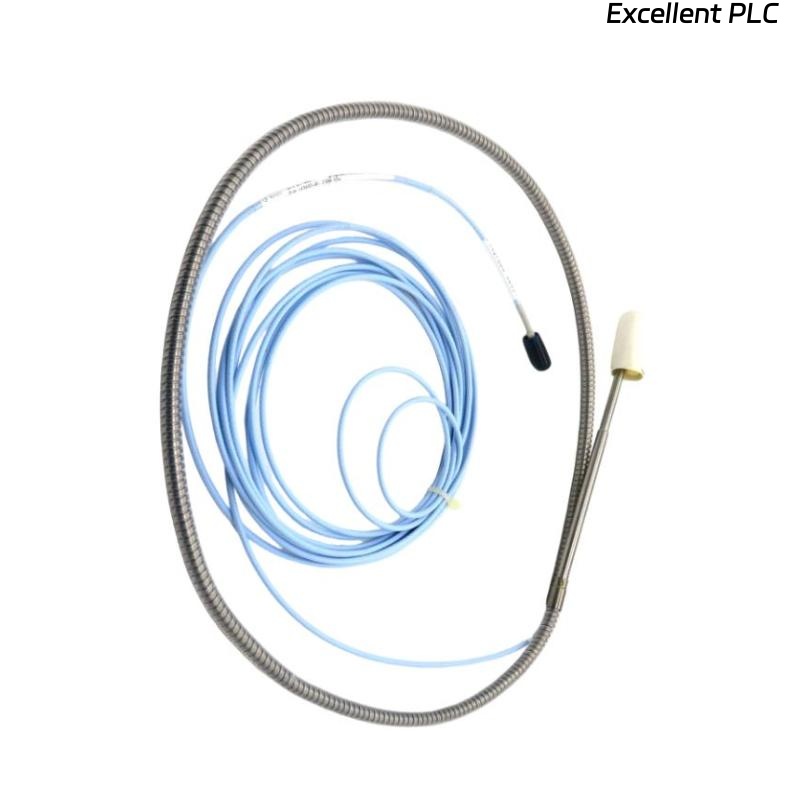

The Bently Nevada P1407030-02006 Double Probe is a high-precision vibration monitoring sensor designed for critical rotating machinery in industrial environments. Manufactured by Bently Nevada, a global leader in condition monitoring and protection systems, this double probe assembly provides enhanced measurement reliability and redundancy for shafts and machinery components operating under severe conditions. The probe’s robust construction ensures stable operation across a wide temperature range, high-speed rotation, and challenging installation environments.

The double probe configuration allows simultaneous measurement of two distinct parameters or provides backup sensing for critical machinery, significantly increasing reliability in monitoring operations. It is widely used in turbines, compressors, generators, and other high-value assets where accurate vibration analysis is crucial for preventive maintenance and operational safety.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | P1407030-02006 |

| Type | Double Probe |

| Measurement Principle | Eddy Current / Proximity Sensing |

| Probe Material | Stainless Steel / High-Temperature Alloy |

| Cable Type | Shielded, Twisted Pair |

| Total Length | Optional (customizable per application) |

| Operating Temperature | -40°C to +120°C |

| Frequency Response | DC to 25 kHz |

| Sensitivity | 50 mV/mil typical |

| Gap Range | 0.1 mm to 2.0 mm |

| Linearity | ±1% of full scale |

| Maximum Shaft Speed | 50,000 RPM |

| Output Impedance | 100 Ohms |

| Shipping Weight | 3 kg |

| Environmental Protection | IP67 / NEMA 4X |

| Mounting Style | Threaded or Flanged |

Applications

The P1407030-02006 Double Probe is designed for critical machinery monitoring where operational reliability and precise vibration detection are essential. Common applications include:

-

Turbines in power generation plants

-

Gas and steam compressors

-

High-speed motors and generators

-

Process pumps and critical rotating equipment in chemical and petrochemical plants

-

Offshore oil and gas machinery

-

Industrial machinery in extreme temperature or high-vibration environments

This double probe is ideal in situations where redundancy is needed for safety-critical machines, or where two independent measurements of the same shaft or surface provide improved diagnostic capability.

Advantages

The P1407030-02006 offers several technical and operational advantages:

-

Redundant Measurement Capability: Dual probes allow simultaneous sensing or backup, reducing risk of measurement failure.

-

High Accuracy: Eddy-current sensing ensures precise, repeatable measurements across varying speeds and gaps.

-

Robust Construction: Withstands high temperature, vibration, and harsh industrial environments.

-

Flexible Installation: Customizable total length and mounting options simplify integration into existing systems.

-

Enhanced Reliability: Designed for critical machinery where failure prevention is essential.

-

Low Maintenance: Durable materials and rugged cable design reduce wear and environmental damage.

FAQ

-

What is the maximum operational temperature for the double probe?

The probe is rated for continuous operation from -40°C to +120°C. -

Can this probe measure high-speed rotating shafts above 50,000 RPM?

The maximum recommended shaft speed is 50,000 RPM. Exceeding this may affect signal accuracy. -

What is the recommended gap range for proper operation?

The typical gap range is 0.1 mm to 2.0 mm. Optimal performance occurs within this range. -

How is the linearity of the probe specified?

The probe provides ±1% of full-scale linearity across its operating gap. -

What type of output does the probe provide?

It generates an analog signal with typical sensitivity of 50 mV/mil. -

Is the probe compatible with standard Bently Nevada monitoring systems?

Yes, it is fully compatible with 3300 XL and other standard Bently Nevada monitoring systems. -

What environmental protections does the probe have?

The probe has IP67/NEMA 4X rating, protecting against dust, water ingress, and harsh industrial conditions. -

Can the probe be mounted in multiple orientations?

Yes, it supports threaded and flanged mounting options for flexible installation. -

What is the cable specification for signal transmission?

It uses a shielded, twisted-pair cable to reduce electromagnetic interference and ensure signal integrity. -

How sensitive is the probe to shaft vibration?

The sensitivity is approximately 50 mV/mil, providing accurate and repeatable measurements for vibration analysis.

Related Models (Same Series or Similar Type)

| Model Number | Type | Key Feature | Weight |

|---|---|---|---|

| P1407030-02001 | Single Probe | Standard measurement | 2.5 kg |

| P1407030-02002 | Double Probe | Dual redundancy | 3.0 kg |

| P1407030-02003 | Triple Probe | Triple sensing | 3.5 kg |

| P1407030-02004 | Double Probe | Extended temperature range | 3.2 kg |

| P1407030-02005 | Single Probe | Compact design | 2.3 kg |

| P1407030-02007 | Double Probe | High-speed shaft monitoring | 3.1 kg |

Popular Models (Same Brand)

| Model Number | Type | Key Feature | Weight |

|---|---|---|---|

| 3300 XL Proximity Probe | Single/Double | Standard in XL monitoring | 2.8 kg |

| 3300 XL Vibration Probe | Single | High sensitivity | 2.7 kg |

| 3300 XL Speed Probe | Single | Shaft speed detection | 2.6 kg |

| 3300 XL Core Probe | Double | Redundant sensing | 3.0 kg |

| 3300 XL Position Probe | Single | Position tracking | 2.5 kg |

| 3300 XL Temperature Probe | Single | Temperature monitoring | 2.9 kg |

Excellent PLC

Excellent PLC