| Company Information | ||||||||

| sales@xmjzjsgs.com | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

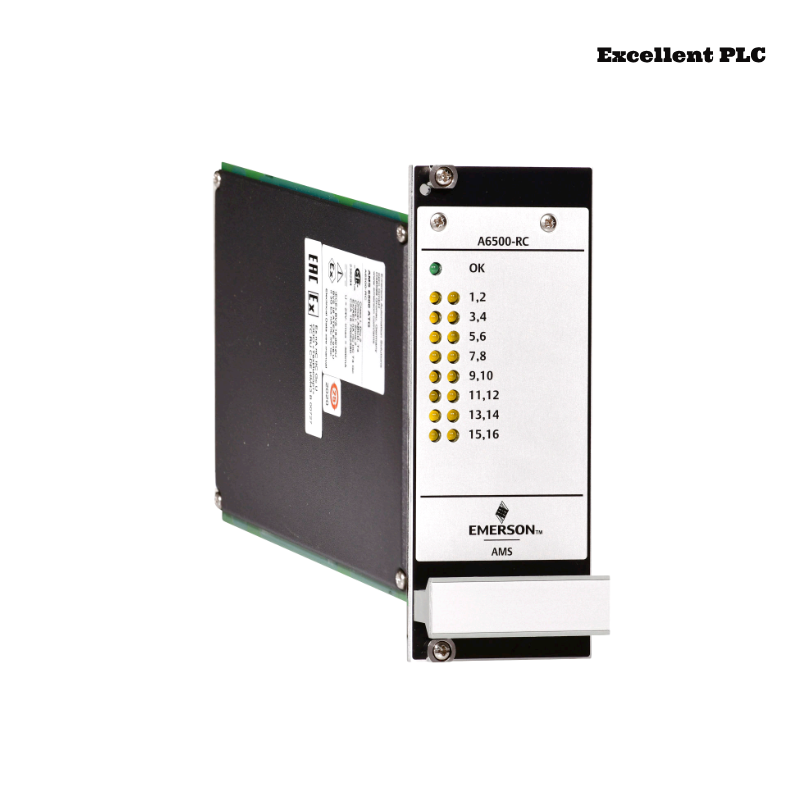

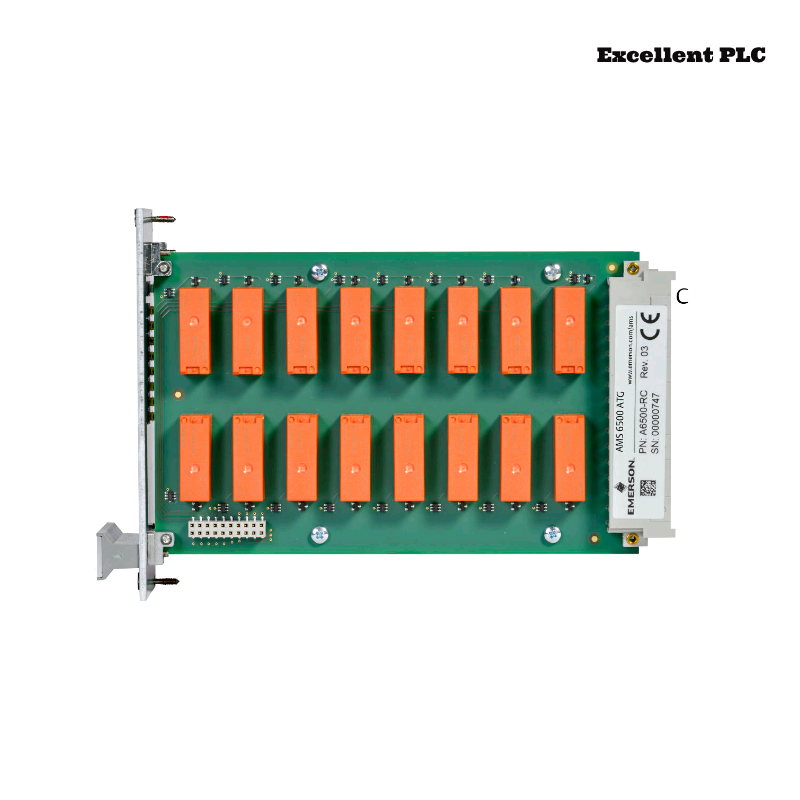

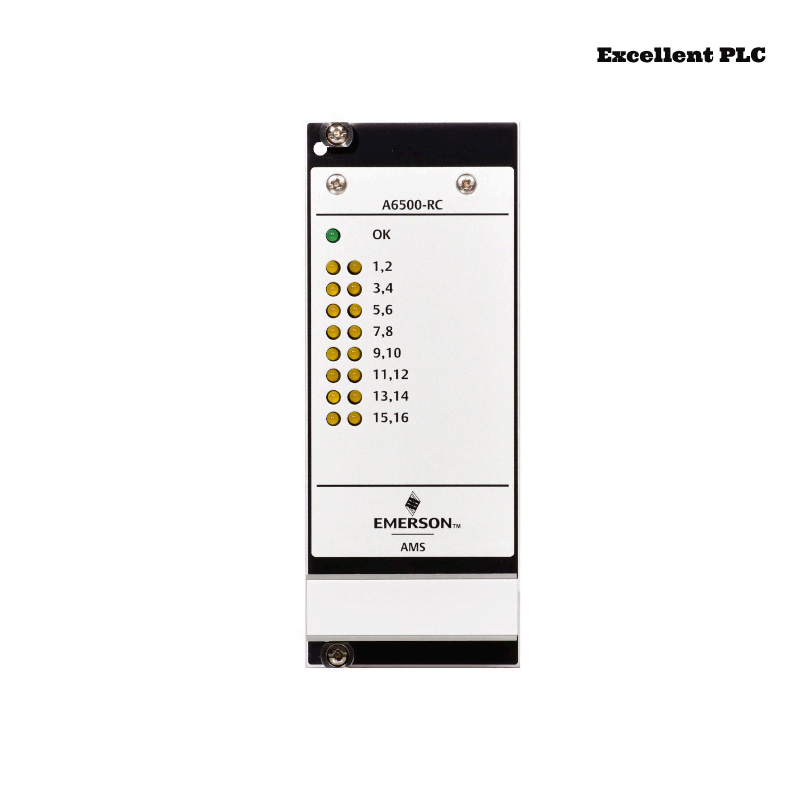

The Emerson A6500-RC is a System Relay Card designed for seamless integration within the AMS 6500 Machinery Health Monitor series. It plays a crucial role in real-time data acquisition, remote system monitoring, and machine condition analysis across various industrial environments.

By enabling remote connectivity and data transmission, the A6500-RC significantly enhances predictive maintenance strategies, helping industries reduce unplanned downtime and maintenance costs. It is widely used in power generation, oil & gas, petrochemical, and manufacturing sectors, where real-time monitoring is critical for operational efficiency.

Product Specifications

| Parameter | Details |

|---|---|

| Manufacturer | Emerson |

| Product Series | AMS 6500 Machinery Health Monitor |

| Model Number | A6500-RC |

| Function | System Relay Card |

| Input/Output | Supports multiple wired and wireless interfaces |

| Communication Protocols | Modbus TCP/IP, OPC-UA, Ethernet, RS-485, and AMS Suite |

| Power Supply | 24V DC |

| Data Transfer Rate | High-speed real-time transmission |

| Remote Access | Secure access via industrial VPN and cloud integration |

| Operating Temperature | -20°C to 70°C |

| Storage Temperature | -40°C to 85°C |

| Humidity | 5% – 95% (non-condensing) |

| Shock Resistance | IEC 60068-2-27 Compliant |

| Vibration Resistance | IEC 60068-2-6 Compliant |

| Dimensions | 133.35 x 50.8 mm |

| Weight | 0.42 kg |

Applications of Emerson A6500-RC

- Remote Machine Monitoring – Enables remote access to critical equipment in power plants, refineries, and factories.

- Industrial IoT Integration – Facilitates real-time machine health data collection for smart manufacturing.

- Oil & Gas Facilities – Helps monitor remote drilling rigs, pipelines, and offshore platforms.

- Chemical and Petrochemical Plants – Ensures safe and efficient operation of large-scale industrial processes.

- Steel & Metal Processing – Supports data-driven maintenance strategies in steel mills.

- Water & Wastewater Treatment – Improves control and monitoring of pumps, blowers, and turbines.

- Mining & Heavy Industry – Provides real-time vibration and temperature monitoring for mining equipment.

- Aerospace & Defense – Used for monitoring critical infrastructure in aerospace manufacturing and military applications.

- Automotive Industry – Ensures smooth operation of robotic production lines and assembly plants.

- Food & Beverage Processing – Enhances reliability of high-speed machinery and conveyors.

Advantages of Emerson A6500-RC

- Real-Time Remote Access – Enables remote monitoring and control from anywhere.

- Seamless Integration – Works with AMS 6500, Modbus, OPC-UA, and Ethernet-based systems.

- High-Speed Data Transfer – Ensures accurate and timely communication of machine health data.

- Industrial-Grade Security – Supports encrypted VPN and secure remote access.

- Reduces Maintenance Costs – Prevents unnecessary site visits by enabling remote diagnostics.

- Compact and Robust Design – Built for harsh industrial environments with shock and vibration resistance.

- Improves Decision-Making – Provides real-time alerts and predictive analytics for maintenance teams.

- Flexible Communication Options – Supports wired and wireless connections for enhanced versatility.

- Scalable and Modular – Can be customized and expanded based on plant requirements.

- Long-Term Reliability – Designed for continuous 24/7 operation in critical applications.

Latest News Titles on Emerson A6500-RC

- Emerson A6500-RC Enhances Remote Vibration Monitoring for Critical Equipment

- How Remote Access with A6500-RC Improves Industrial Predictive Maintenance

- Emerson Introduces Advanced Remote Communication Capabilities for AMS 6500 Series

- A6500-RC: The Future of Remote Condition Monitoring in Manufacturing

- Emerson Expands Industrial IoT Solutions with Secure Remote Monitoring

- Reducing Downtime: How Emerson’s Remote Communication Module Saves Costs

- Enhancing Safety in Offshore Oil & Gas Operations with Emerson A6500-RC

- Industrial Connectivity Revolution: How A6500-RC Integrates with Smart Factories

- Emerson’s Investment in Advanced Predictive Maintenance Technologies

- Remote Vibration Monitoring: The Key to Optimized Machine Health Management

Frequently Asked Questions (FAQ)

-

What is the primary function of the Emerson A6500-RC?

It is a System Relay Card that enables real-time data access, monitoring, and diagnostics for industrial machinery. -

Which industries benefit the most from this system?

It is widely used in oil & gas, power generation, petrochemical, manufacturing, and aerospace sectors. -

How does the A6500-RC integrate with other Emerson products?

It works with AMS 6500, AMS Suite, and various industrial communication protocols like Modbus and OPC-UA. -

What communication protocols are supported?

The A6500-RC supports Ethernet, Modbus TCP/IP, OPC-UA, RS-485, and secure remote VPN access. -

Can the A6500-RC be used for wireless monitoring?

Yes, it supports wired and wireless connectivity for flexible industrial applications. -

What is the power supply requirement?

It operates on 24V DC for industrial environments. -

What is the size and weight of the A6500-RC?

The module measures 133.35 x 50.8 mm and weighs 0.42 kg. -

Is the A6500-RC suitable for harsh environments?

Yes, it complies with IEC standards for shock, vibration, and extreme temperatures. -

How does it help reduce maintenance costs?

By enabling remote diagnostics and monitoring, it reduces the need for on-site inspections and reactive maintenance. -

Can it integrate with cloud-based industrial platforms?

Yes, the A6500-RC supports cloud integration for centralized machine health data management.

Related Models in the Same Series

| Model Number | Description |

|---|---|

| A6500-LC | Vibration monitoring and protection module |

| A6500-UM | Universal monitoring system |

| A6500-AT | Advanced analysis tool for vibration monitoring |

| A6500-SM | Sensor module for additional data inputs |

| A6500-TM | Temperature monitoring extension |

| AMS 2140 | Portable vibration analyzer |

| AMS 9420 | Wireless vibration transmitter |

| CSI 6500 | Comprehensive condition monitoring system |

| CSI 2140 | Multi-channel vibration analyzer |

| CSI 9420 | Wireless monitoring system |

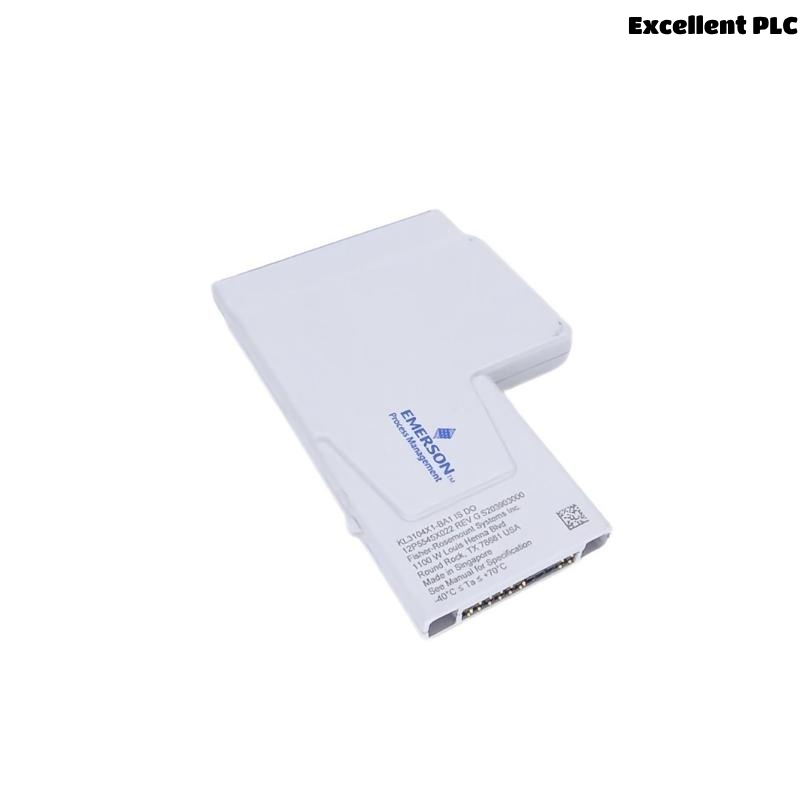

Popular Emerson Models

| Model Number | Description |

|---|---|

| AMS 6500 | Advanced online condition monitoring system |

| AMS TREX | Portable field communicator |

| DeltaV PK | Process control system for automation |

| Ovation DCS | Distributed control system for power plants |

| RX3i | Programmable automation controller |

| Micro Motion 5700 | High-performance flow transmitter |

| Rosemount 3051 | Smart pressure transmitter |

| Rosemount 2140 | Vibration fork liquid level switch |

| Emerson PACSystems | Industrial automation controller |

| Emerson S-Series | Compact PLC for machine automation |

Excellent PLC

Excellent PLC