| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

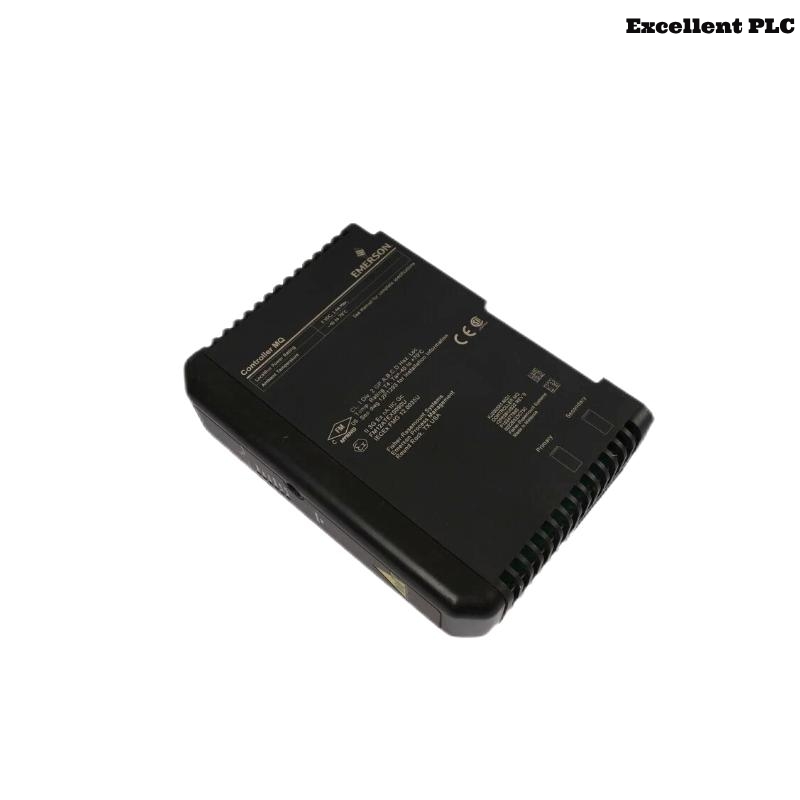

The Emerson KJ2005X1-MQ1 MQ Controller is a powerful, high-speed modular controller developed for the DeltaV™ distributed control system (DCS). Engineered for mission-critical process automation, the MQ Controller is designed to deliver deterministic performance, large-scale control capability, and enhanced integration with a broad range of I/O types and protocols.

This controller operates as the brain of the DeltaV system, managing sophisticated control strategies across a wide range of industrial applications. With robust reliability, system-wide redundancy options, and full system diagnostics, it ensures operational continuity and real-time responsiveness. The MQ Controller is particularly suited for industries requiring high integrity and precision, such as refining, power generation, pharmaceuticals, and advanced manufacturing.

Product Specifications

| Parameter | Description |

|---|---|

| Product Name | MQ Controller |

| Model Number | KJ2005X1-MQ1 |

| Manufacturer | Emerson Process Management |

| System Platform | DeltaV™ DCS |

| Processor Architecture | Motorola PowerPC 32-bit RISC |

| Memory Configuration | 64 MB Flash / 32 MB DRAM |

| Supported I/O Channels | Up to 30,000 I/O points |

| Redundancy Capability | Yes, supports hot standby redundancy |

| Communication Interfaces | Ethernet, DeltaV Protocol, OPC |

| Mounting Type | Horizontal rail mount (DeltaV chassis) |

| Status Indicators | LEDs for power, activity, fault, and redundancy |

| Power Consumption | Typically < 5W |

| Operating Temperature Range | -40°C to +70°C (-40°F to +158°F) |

| Storage Temperature Range | -40°C to +85°C (-40°F to +185°F) |

| Humidity | 5% to 95% RH non-condensing |

| Certifications | CE, ATEX Zone 2, CSA, UL, IECEx, GOST |

| Firmware Upgrades | Supported via DeltaV control software |

| Advanced Diagnostics | Built-in system health and diagnostic alerts |

| Dimensions (H x W x D) | 120 x 102 x 55 mm |

| Weight | 0.454 kg |

Product Applications

-

Oil & Gas Production

Used for upstream and downstream automation such as wellhead control, compressor stations, and refining units. -

Chemical Manufacturing

Provides tight control over reaction processes, distillation columns, and feed systems. -

Power Generation

Manages plant turbine controls, auxiliary systems, emission systems, and electrical load balancing. -

Pharmaceutical Plants

Enables batch control processes, environmental control systems, and serialization tracking. -

Water & Wastewater Treatment

Regulates pumps, clarifiers, and chemical dosing systems with fault-tolerant performance. -

Food & Beverage Production

Used in batch and continuous process lines to ensure hygiene compliance and consistency. -

Mining & Metals

Controls materials handling, smelting operations, and flotation circuits under extreme conditions.

Product Advantages

-

Redundant Control Architecture

The MQ Controller supports hot-standby redundancy for mission-critical applications, providing uninterrupted control even in failure scenarios. -

Real-Time Control Performance

Offers deterministic processing, making it ideal for applications that demand fast response and high reliability. -

Broad Integration Capability

Easily integrates with field I/O, third-party devices, and legacy systems using OPC and Ethernet protocols. -

Diagnostic Intelligence

Built-in monitoring and diagnostics enable early detection of system faults, minimizing downtime. -

Compact Yet Scalable Design

Space-efficient footprint supports both small and large-scale automation systems without sacrificing functionality. -

Industry Compliance

Certified for use in hazardous and regulated environments, ensuring safety and legal compliance. -

Energy Efficient Operation

Consumes low power and supports sustainable plant operations with minimal thermal output. -

Future-Ready Platform

Fully compatible with DeltaV system upgrades and software expansions to adapt to changing operational needs.

FAQ

-

What is the main difference between the MQ and MX Controllers?

The MQ controller is optimized for modular and flexible deployment, offering scalability in distributed environments with similar core performance to the MX. -

Is this controller hot-swappable?

No, the controller must be removed during maintenance but supports system redundancy to avoid downtime. -

Can I use it in ATEX-certified environments?

Yes, the KJ2005X1-MQ1 is ATEX Zone 2 certified for hazardous area applications. -

How many I/O points can this controller handle?

It supports up to 30,000 I/O channels in a DeltaV networked system. -

Does it require a specific chassis for mounting?

Yes, it must be mounted on a compatible DeltaV chassis for secure installation and communication. -

Can firmware be upgraded while online?

Firmware upgrades require a scheduled system window unless redundancy is configured for failover updates. -

How is redundancy implemented?

A redundant pair of MQ controllers is configured, with one operating as primary and the other on standby. -

What is the lifecycle support status for this model?

Emerson offers long-term lifecycle support under its DeltaV lifecycle services, including spare parts and service. -

Is the MQ controller compatible with wireless I/O modules?

Yes, when used with DeltaV wireless gateways and network configurations. -

How does it handle diagnostic reporting?

The controller continuously monitors its own status and communicates alerts via DeltaV diagnostic displays.

Related or Compatible Models from the Same Series

| Model Number | Description | Compatibility | Redundancy | Weight |

|---|---|---|---|---|

| KJ2005X1-BA1 | MX Controller | DeltaV System | Yes | 0.60 kg |

| KJ2003X1-BB1 | Compact Process Controller | DeltaV System | Optional | 0.58 kg |

| KJ3002X1-BB1 | Redundant I/O Controller | DeltaV System | Yes | 0.65 kg |

| KJ4010X1-BG1 | Foundation Fieldbus Controller | DeltaV FF Integration | No | 0.59 kg |

| KJ3222X1-BA1 | I/O Subsystem Controller | DeltaV | Yes | 0.63 kg |

| KJ1501X1-BE1 | DeltaV Smart Switch | DeltaV Network | No | 0.55 kg |

Popular Emerson Models (Same Brand)

| Model Number | Description | Primary Use | System | Weight |

|---|---|---|---|---|

| AMS Trex 375 | Field communicator for smart instruments | Field diagnostics | AMS Suite | 0.85 kg |

| ROC809 | Remote Terminal Unit | SCADA and Oilfield | Remote Operations | 1.10 kg |

| DeltaV CHARM I/O Card | CHARM-based modular I/O | Flexible field integration | DeltaV | 0.90 kg |

| Ovation OCR1100 | Control processor unit | Power generation automation | Ovation | 1.25 kg |

| PACSystems RX3i | High-performance PAC | Discrete/hybrid automation | PACSystems | 1.30 kg |

| DeltaV M-Series CPU | Classic CPU controller | Legacy system support | DeltaV M-Series | 1.00 kg |

Excellent PLC

Excellent PLC