| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

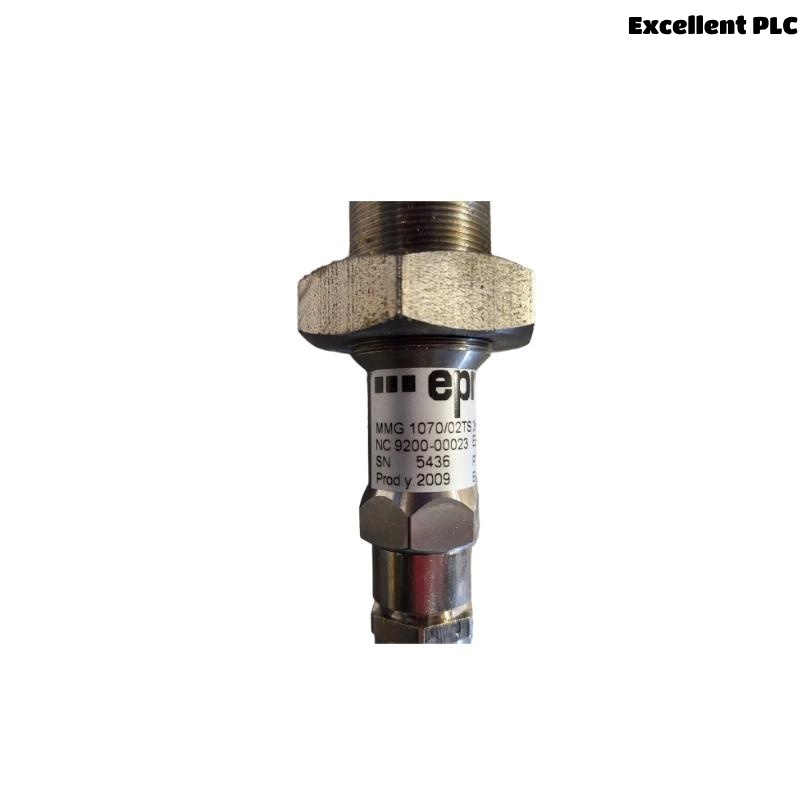

The Epro MMG1070/02TS Eddy Current Displacement Sensor is a precision-engineered non-contact measuring device used to monitor the displacement, vibration, or position of conductive targets. Operating based on the eddy current principle, this sensor delivers highly accurate and stable measurements even in harsh industrial environments.

This sensor is a key component in rotating machinery monitoring systems, often integrated into condition monitoring or protection systems. The MMG1070/02TS is designed for long-term reliability, minimal drift, and robust immunity to contaminants, making it ideal for turbomachinery, compressors, motors, and pumps where exact shaft position and vibration data are critical.

Product Specifications

| Parameter | Description |

|---|---|

| Model | MMG1070/02TS |

| Sensor Type | Eddy Current Displacement Sensor |

| Measurement Principle | Electromagnetic Induction (Eddy Current) |

| Measurement Range | 0.25 mm – 2.0 mm |

| Linear Range | Typically 80% of measurement range |

| Linearity | ±1% of Full Scale |

| Output Signal | Analog Voltage Output (via compatible driver) |

| Frequency Response | Up to 10 kHz |

| Operating Temperature Range | -35°C to +180°C (sensor head) |

| Material (Sensor Head) | Stainless Steel (typically AISI 303 or similar) |

| Probe Thread Size | M8 × 1 or custom threading based on version |

| Cable Length | 3 meters |

| Environmental Protection | IP65 or higher (depending on installation and sealing) |

| Insulation Resistance | >100 MΩ at 500 VDC |

| Mounting | Threaded mount with locking nuts |

| Compatible with | CON041, CON011, MMS3120, MMS6110, and other Epro drivers |

| Weight | 0.9 kg |

| Certifications | CE, RoHS, ISO 9001 compliant |

Product Applications

The MMG1070/02TS sensor is extensively used in industrial machinery condition monitoring, especially for non-contact proximity and vibration analysis. Key application sectors include:

-

Steam and Gas Turbines – For shaft displacement, eccentricity, and vibration monitoring.

-

Compressors and Pumps – Measuring axial thrust position and rotor dynamics.

-

Electric Motors – Detecting bearing wear or shaft imbalance.

-

Gearboxes and Drives – Monitoring gear shaft runout or misalignment.

-

Hydro Power Plants – Non-contact measurement for large rotating elements.

-

Petrochemical and Refining Plants – Monitoring rotating equipment in explosive or hazardous environments.

Product Advantages

-

High Precision Measurement – Accurate readings with excellent linearity across the measurement range.

-

Non-Contact Operation – No mechanical wear, ideal for high-speed rotating machinery.

-

Wide Temperature Range – Withstands harsh industrial conditions, suitable for both hot and cold zones.

-

Corrosion-Resistant Housing – Made from durable stainless steel for long-term deployment.

-

Robust EMI Immunity – Operates reliably in high electromagnetic interference environments.

-

Compatible with Epro Systems – Seamlessly integrates with CON041, MMS3120, and other Epro monitoring modules.

-

Flexible Mounting – Threaded design for easy installation and alignment in tight spaces.

-

Reliable in Oil and Dust – IP-rated protection for operation in oily or dusty environments.

-

Long Service Life – Designed for continuous operation without recalibration.

-

Global Standards Compliant – Certified to meet international safety and quality regulations.

Frequently Asked Questions (FAQ)

-

What is the primary use of the MMG1070/02TS sensor?

It is used to measure shaft displacement, vibration, and position in industrial rotating machinery. -

What type of measurement principle does it use?

It uses the eddy current principle for non-contact displacement sensing. -

Can the sensor withstand high temperatures?

Yes, the sensor head can operate at temperatures up to 180°C. -

Is it compatible with other Epro modules?

Yes, it works with CON041, CON021, MMS3120, and MMS6110 modules. -

Does it require recalibration over time?

Under standard operating conditions, recalibration is rarely needed due to its stable construction. -

What is the sensor’s protection rating?

The sensor typically offers IP65 or higher protection depending on installation. -

Can I use it in hazardous environments?

Yes, with proper system integration and housing, it is suitable for hazardous zones. -

How is the sensor mounted?

It features a threaded body and is mounted using standard locking nuts. -

What is the cable length provided?

Standard length is 3 meters, but longer versions are available on request. -

What materials is the sensor made from?

The sensing head is made of corrosion-resistant stainless steel, usually AISI 303 or similar.

Related Models (Same Series or Functionality)

| Model | Description | Range | Temp Range (°C) | Output Type | Weight (g) |

|---|---|---|---|---|---|

| MMG1070/01TS | Eddy current sensor, standard version | 0.2–1.6 mm | -35 to +180 | Analog (via CON041) | 170 |

| PR6423/003-030 | Eddy current probe for axial monitoring | 0.25–2.0 mm | -35 to +180 | Analog Voltage | 190 |

| PR6424/012-030 | High-temp eddy current sensor | 0.5–3.0 mm | -35 to +200 | Analog (with driver) | 210 |

| PR6424/01CS | Compact shaft position sensor | 0.25–1.6 mm | -35 to +180 | Analog | 160 |

| MMG1050/03 | Eddy current probe for fine vibration | 0.1–1.0 mm | -35 to +150 | Analog | 150 |

| MMS6120 | Dual-channel monitor module (works with MMG1070) | – | – | Digital / Relay | 320 |

Popular Models from Epro (Other Product Categories)

| Model | Function | Type | Compatibility | Weight (g) |

|---|---|---|---|---|

| CON041 | Eddy current signal converter | Signal Conditioning | Works with MMG/PR642x | 250 |

| MMS3120/022-100 | Vibration monitoring module | Monitoring Module | PR642x, MMG1070 | 420 |

| MMS6110 | Multi-channel monitoring system | Monitoring Module | PR642x, MMG sensors | 450 |

| PR9268/601-000 | Speed sensor | Velocity Sensor | General-purpose | 180 |

| CON011 | Compact signal converter | Signal Conditioner | PR6423/PR6424 series | 230 |

| PR6426/010-010 | High-resolution eddy current sensor | Displacement Sensor | CON041, MMS6110 | 200 |

Excellent PLC

Excellent PLC