| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

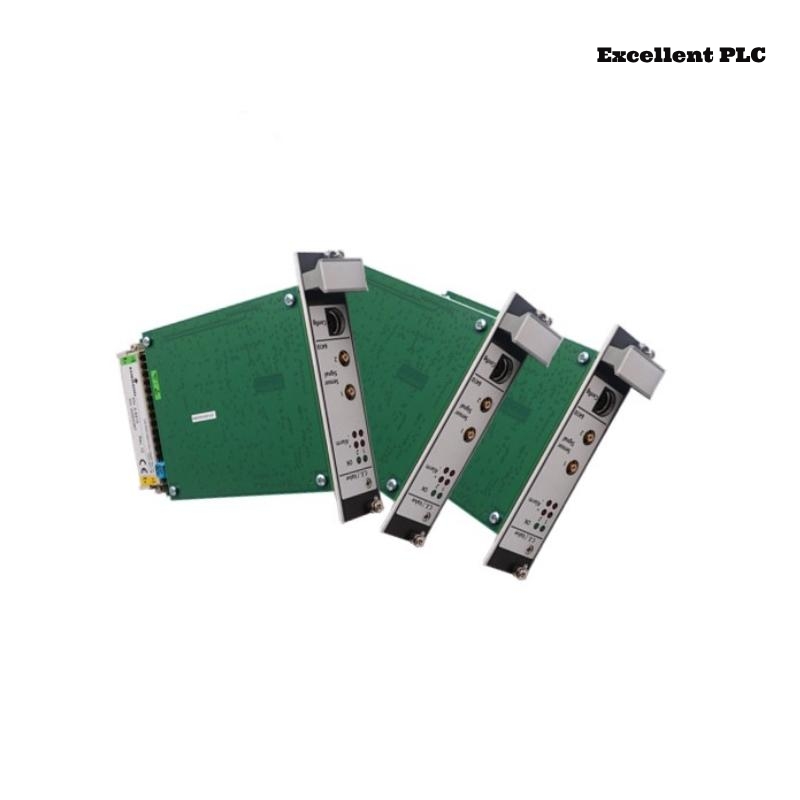

The EPRO MMS6310 is a dual-channel key-pulse monitor designed for critical machinery protection within the Emerson MMS 6000 system. Manufactured by EPRO, a company renowned for its reliable and versatile machine monitoring and protection solutions, the MMS6310 is particularly suited for applications requiring dual keystroke pulse inputs.It monitors speed, rotation direction, and keyphasors from rotating shafts using magnetic pickups or pulse generators.This device is ideal for applications with multiple rotating shafts, ensuring comprehensive monitoring and control.

Product Specifications

Below is a table detailing the key specifications of the EPRO MMS6310:

| Specification | Details |

|---|---|

| Channels | 2 (Dual-Channel Monitoring) |

| Input Signals | Magnetic pickups, pulse generators, proximity switches, encoders |

| Speed Range | Wide range depending on application |

| Outputs | Digital alarm outputs, speed data |

| Communication | RS 232 and RS 485 interfaces |

| Power Supply | 18–31.2 V DC |

| Dimensions | 30 x 128.4 x 160 mm |

| Weight | 0.32 kg |

| Operating Temperature | -20°C to +70°C |

| Mounting | DIN rail |

Product Advantages

-

Dual-Channel Monitoring: Allows simultaneous monitoring of two independent channels, making it ideal for applications with multiple rotating shafts, ensuring comprehensive monitoring and control.

-

Wide Range of Input Signals: Accepts various input signals, including key pulses, proximity switches, and encoders, offering flexibility and compatibility with diverse sensor types.

-

High Accuracy and Reliability: Renowned for its high accuracy, reliability, and user-friendly design, it ensures optimal performance and ease of operation.

-

Versatile Applications: Suitable for a wide variety of applications, including pumps, fans, compressors, turbines, and generators.

Latest Product Reports

As of the latest available information, the EPRO MMS6310 continues to be recognized for its robust performance in industrial automation applications. Its precise monitoring capabilities for key signals enhance system reliability and efficiency.

The device’s compatibility with various input signals and its dual-channel monitoring feature make it a preferred choice for critical machinery protection. Users have reported satisfaction with its high accuracy, reliability, and user-friendly design, ensuring optimal performance and ease of operation.

Frequently Asked Questions (FAQs)

-

What is the primary function of the EPRO MMS6310?

- The EPRO MMS6310 is designed to monitor key pulses from rotating shafts, providing critical data on speed, rotation direction, and keyphasors, essential for machinery protection and control.

-

Can the MMS6310 monitor two different shafts simultaneously?

- Yes, the dual-channel design allows for simultaneous monitoring of two independent shafts, each running at different speeds.

-

What types of input signals are compatible with the MMS6310?

- The MMS6310 accepts various input signals, including magnetic pickups, pulse generators, proximity switches, and encoders, offering flexibility and compatibility with diverse sensor types.

-

How does the MMS6310 communicate with other systems?

- It features RS 232 and RS 485 interfaces for seamless integration and communication with other control systems.

-

What is the operating temperature range for the MMS6310?

- The device operates effectively within a temperature range of -20°C to +70°C.

-

Is the MMS6310 suitable for use in hazardous environments?

- While the MMS6310 is designed for industrial applications, it’s essential to consult the manufacturer’s guidelines and certifications to determine its suitability for specific hazardous environments.

-

What are the mounting options for the MMS6310?

- The MMS6310 is designed for DIN rail mounting, facilitating easy installation and integration into existing systems.

-

Does the MMS6310 support redundant power supply configurations?

- Yes, it features redundant supply input via two supply inputs, decoupled via diodes, ensuring continuous operation even if one power source fails.

-

Can the MMS6310 be integrated into existing Emerson MMS 6000 systems?

- Yes, the MMS6310 is designed to be fully compatible with Emerson MMS 6000 systems, allowing for seamless integration and enhanced machinery protection.

-

What maintenance is required for the MMS6310?

- Regular maintenance includes checking connections, verifying signal integrity, and ensuring the device operates within specified environmental conditions.

Related Models (Same Series or Similar Functionality)

| Model Number | Description |

|---|---|

| MMS6110 | Dual-channel shaft vibration monitor for precise condition monitoring |

| MMS6120 | Dual-channel bearing vibration monitor with advanced diagnostics |

| MMS6210 | Single-channel speed monitor designed for turbine and compressor applications |

| MMS6220 | Dual-channel speed monitor for high-speed rotating equipment |

| MMS6312 | Advanced key-pulse monitor with extended signal processing capabilities |

| MMS6350 | Phase reference monitor for shaft alignment and phase measurement |

| MMS6410 | Temperature monitor for industrial rotating machinery |

| MMS6450 | Multi-function protection system integrating speed and vibration monitoring |

| MMS6500 | Integrated machinery protection system with multiple input options |

| MMS6700 | Advanced signal processing unit for real-time machinery diagnostics |

Popular Models from the Same Brand (EPRO)

| Model Number | Description |

|---|---|

| PR6423/10 | High-precision eddy current sensor for shaft vibration measurement |

| PR6424/10 | Proximity sensor used for non-contact displacement measurement |

| PR9268/10 | Accelerometer for vibration monitoring in industrial machinery |

| CON011 | Signal converter module designed for eddy current sensor integration |

| CON021 | Advanced signal converter for PR6423/PR6424 series sensors |

| MMS3110 | Single-channel vibration monitor with configurable output settings |

| MMS3120 | Dual-channel vibration monitor for rotating machinery diagnostics |

| MMS3150 | Multi-functional condition monitoring module |

| MMS3200 | High-speed data acquisition module for predictive maintenance |

| MMS3400 | Comprehensive machinery protection system with modular design |

Excellent PLC

Excellent PLC