| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

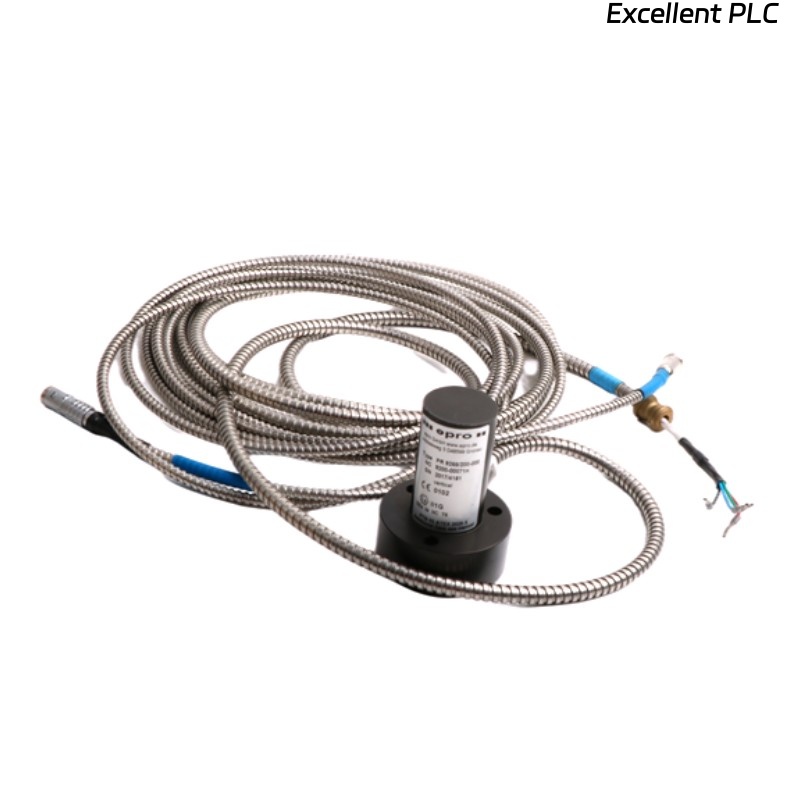

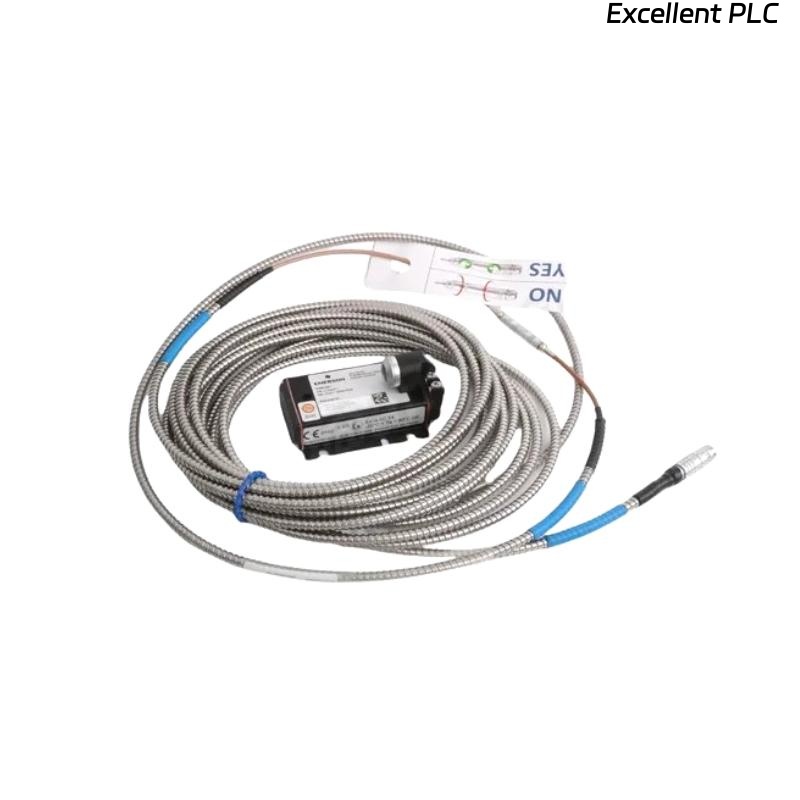

The Epro PR6423/000-030 8mm Eddy-Current Sensor is a high-performance non-contact sensor specifically designed for vibration and displacement measurement in rotating machinery. It is commonly used in conjunction with Epro monitoring systems such as the MMS 6000 and other vibration protection devices. The sensor operates based on the eddy-current principle, providing accurate, stable, and real-time measurement of shaft vibration or relative displacement even under harsh environmental conditions.

Product Advantages

-

High Measurement Accuracy – Delivers precise readings of shaft vibration and displacement with minimal signal drift.

-

Robust Construction – Built to withstand harsh industrial environments including high temperatures and electromagnetic interference.

-

Wide Frequency Range – Supports accurate vibration monitoring across a broad spectrum of frequencies.

-

Non-Contact Measurement – Eliminates mechanical wear and ensures consistent performance over long periods.

-

Easy Integration – Compatible with Epro and Emerson monitoring systems for seamless setup and operation.

-

Stable Output Signal – Maintains signal integrity even under fluctuating operational conditions.

-

Extended Temperature Tolerance – Designed to perform reliably across a wide temperature range.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Epro PR6423/000-030 |

| Sensor Type | Eddy-Current Vibration/Displacement Sensor |

| Sensor Head Diameter | 8 mm |

| Measurement Range | Typically up to 2 mm (depends on system configuration) |

| Sensitivity | 4 mV/µm (nominal) |

| Frequency Range | 0 to 10 kHz |

| Linearity | ≤ ±1% of full scale |

| Power Supply | Supplied through proximity transducer system (e.g., PR6426, CON0x series) |

| Operating Temperature | -35°C to +180°C |

| Weight | 0.1 kg |

| Material | Stainless steel housing |

| Output Signal | Voltage proportional to distance/vibration amplitude |

| Protection Class | IP65 or higher depending on installation |

Product Applications

-

Steam and gas turbines

-

Compressors and blowers

-

Generators and large electric motors

-

Pumps and fans in process industries

-

Gearboxes and speed-increasing units

-

Industrial machinery requiring continuous vibration monitoring

FAQ

Q1: What is the principle behind the PR6423/000-030 sensor?

The sensor works on the eddy-current principle, where a magnetic field induces eddy currents in the conductive target, and changes in these currents are used to determine the distance or vibration amplitude.

Q2: Which monitoring systems are compatible with this sensor?

It is fully compatible with Epro and Emerson monitoring systems such as MMS 6000, PR6426 converter units, and CON0x signal conditioners.

Q3: What type of signal output does the PR6423/000-030 provide?

It provides a voltage output proportional to the displacement or vibration of the monitored surface.

Q4: Can this sensor operate in environments with strong electromagnetic fields?

Yes, it is designed with excellent EMI shielding to ensure stable performance in environments with strong electromagnetic interference.

Q5: How is the sensor calibrated for accurate readings?

The sensor is factory-calibrated to specific target materials and gaps, and calibration data are maintained through the associated converter unit.

Q6: What is the recommended mounting method for this sensor?

It is typically mounted in a threaded holder or bracket, ensuring proper alignment and air gap between the sensor and the target shaft.

Q7: Can the sensor be used for both vibration and axial displacement monitoring?

Yes, it can measure both radial vibration and axial displacement depending on installation orientation and configuration.

Q8: What is the linearity specification of the PR6423/000-030?

The linearity is typically within ±1% of the full-scale measurement range.

Q9: Does cable length affect sensor accuracy?

Yes, cable length can affect calibration and signal integrity; therefore, standard lengths are recommended unless recalibrated with the corresponding converter.

Q10: Is this sensor suitable for high-temperature applications?

Yes, it supports continuous operation up to +180°C, making it ideal for high-temperature environments like turbines and compressors.

Related or Same-Series Models

| Model | Description | Sensor Head Diameter | Cable Length | Application |

|---|---|---|---|---|

| PR6423/000-031 | Eddy-current sensor variant | 8 mm | 5 m | General industrial vibration monitoring |

| PR6423/000-040 | High-temperature version | 8 mm | 3 m | Turbine bearing monitoring |

| PR6423/010-030 | Extended range type | 10 mm | 3 m | Shaft displacement measurement |

| PR6423/000-010 | Standard eddy-current probe | 5 mm | 3 m | Compact machinery |

| PR6423/000-050 | Enhanced EMI shielded version | 8 mm | 3 m | Harsh environment use |

| PR6423/000-100 | Custom calibration version | 8 mm | 5 m | Precision monitoring systems |

Popular Models from the Same Brand

| Model | Product Type | Key Feature | Typical Application | Weight |

|---|---|---|---|---|

| PR6426/000-030 | Proximity Transducer | Signal converter for eddy-current sensors | Used with PR6423 probes | 0.25 kg |

| PR9268/203-000 | Vibration Transmitter | 4-20 mA output | General vibration monitoring | 0.3 kg |

| CON021 | Signal Conditioner | Two-channel configuration | MMS systems | 0.2 kg |

| MMS 6000 | Machinery Monitoring System | Multi-channel vibration analysis | Turbine and compressor protection | — |

| PR6424/000-030 | Eddy-Current Sensor (5mm) | Compact design | Tight installation spaces | 0.08 kg |

| PR6425/010-030 | Eddy-Current Sensor (10mm) | Long-range detection | Large shaft monitoring | 0.12 kg |

Excellent PLC

Excellent PLC