| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

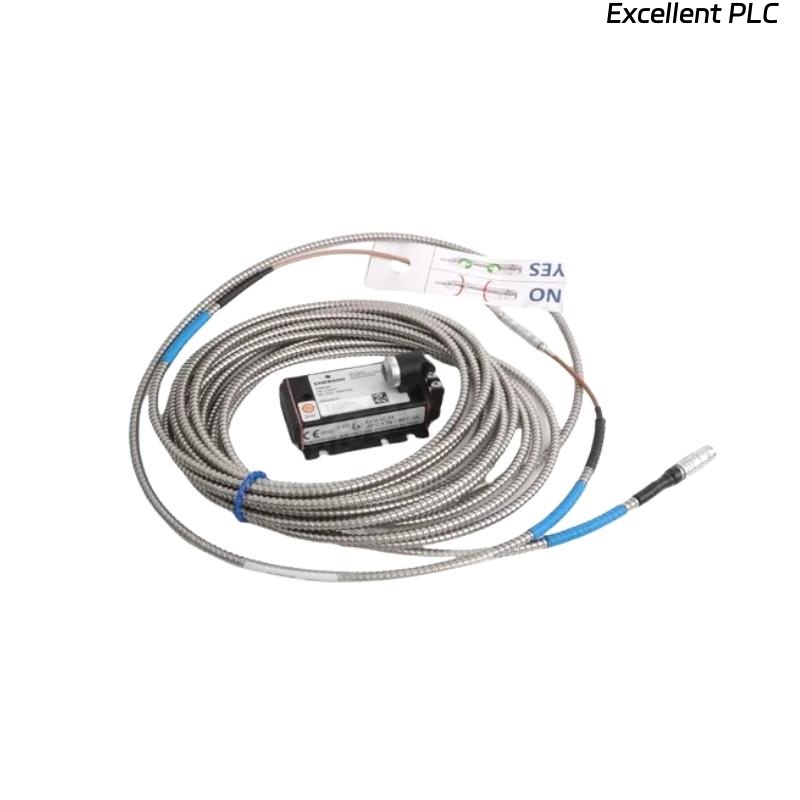

The Epro PR6423/000-031-CN is an 8 mm Eddy Current Sensor designed for highly accurate measurement of displacement, vibration, and position in industrial and research applications. This sensor belongs to the PR6423 series, which is known for robust construction, repeatable precision, and long-term stability under challenging operational conditions.

The PR6423/000-031-CN operates on non-contact eddy current principles, ensuring wear-free operation and consistent performance over time. Its stainless steel housing provides protection against mechanical stress, vibration, and environmental factors, making it suitable for integration into turbines, pumps, motors, and other rotating machinery.

This sensor delivers stable analog output signals compatible with industrial controllers, vibration monitoring systems, and data acquisition platforms. Its compact 8 mm sensor head allows installation in tight spaces, while maintaining high measurement reliability, making it ideal for predictive maintenance, condition monitoring, and laboratory research in mechanical engineering.

Technical Specifications

| Parameter | Specification |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Sensor Head Diameter | 8 mm |

| Weight | 0.1 kg |

| Measurement Range | 0–31 mm |

| Linearity | ±0.5% F.S. |

| Operating Temperature | -40°C to +125°C |

| Output Signal | Analog voltage / current |

| Housing Material | Stainless Steel |

| Connector Type | CN |

| Frequency Response | Up to 10 kHz |

| Power Supply | 24 VDC nominal |

Applications

The PR6423/000-031-CN sensor is employed in a wide variety of industrial and research environments where precise monitoring is essential:

-

Rotating Machinery Monitoring: Detecting shaft vibration, rotor displacement, and misalignment.

-

Turbines and Generators: Measuring rotor and shaft movement to prevent operational failures.

-

Pumps and Compressors: Monitoring axial and radial displacement to optimize performance.

-

Motors and Gearboxes: Detecting imbalance, bearing wear, and mechanical degradation.

-

Research and Development: Laboratory testing of mechanical systems, vibration studies, and component validation.

-

Condition-Based Maintenance Systems: Integration into predictive maintenance platforms for real-time equipment health monitoring.

Advantages

The PR6423/000-031-CN sensor provides multiple benefits:

-

High Accuracy: Ensures precise and repeatable measurements with minimal deviation.

-

Compact Design: 8 mm sensor head allows installation in restricted spaces.

-

Non-Contact Operation: Prevents wear and reduces maintenance requirements.

-

Robust Construction: Stainless steel housing offers resistance to mechanical stress and corrosion.

-

Wide Operating Temperature Range: Operates reliably from -40°C to +125°C.

-

High-Frequency Response: Captures rapid vibration and transient events effectively.

-

Versatile Output: Compatible with analog voltage or current systems for integration with industrial controllers.

-

Long-Term Stability: Maintains accuracy and repeatability over extended operational periods.

FAQ

-

What is the maximum measurement range of the PR6423/000-031-CN?

The sensor can measure displacements up to 31 mm with high linearity. -

Can this sensor operate under extreme temperatures?

Yes, it functions reliably from -40°C to +125°C. -

What type of output signals does the sensor provide?

It provides analog voltage or current outputs compatible with industrial control systems. -

How precise is the PR6423/000-031-CN?

It maintains linearity within ±0.5% of the full-scale measurement range. -

Is the sensor suitable for vibration monitoring?

Yes, the frequency response up to 10 kHz allows accurate detection of high-speed vibrations. -

What materials are used for the sensor housing?

The housing is stainless steel, providing mechanical durability and corrosion resistance. -

Can the sensor detect both axial and radial displacement?

Yes, the eddy current principle allows detection in both axial and radial directions. -

Is the sensor compatible with automated monitoring systems?

Yes, the analog outputs allow integration into industrial controllers and predictive maintenance platforms. -

Does the sensor require calibration before use?

Factory calibration ensures accuracy, but field calibration is recommended for critical applications. -

What connector type does this sensor use?

It uses a CN connector for reliable and secure electrical connection.

Recommended Related Models (Same Series or Similar)

| Model | Sensor Head Diameter | Measurement Range | Weight |

|---|---|---|---|

| PR6423/005-010-CN | 5 mm | 10 mm | 0.08 kg |

| PR6423/010-020-CN | 10 mm | 20 mm | 0.12 kg |

| PR6423/012-025-CN | 12 mm | 25 mm | 0.13 kg |

| PR6423/015-030-CN | 15 mm | 30 mm | 0.15 kg |

| PR6423/017-030-CN | 8 mm | 30 mm | 0.10 kg |

| PR6423/01M-010 | 8 mm | 10 mm | 0.10 kg |

Popular Models from Epro (Same Brand)

| Model | Sensor Head Diameter | Measurement Range | Weight |

|---|---|---|---|

| PR6424/014-040 | 14 mm | 40 mm | 0.17 kg |

| PR6424/022-050 | 22 mm | 50 mm | 0.22 kg |

| PR6425/010-030 | 10 mm | 30 mm | 0.14 kg |

| PR6425/018-035 | 18 mm | 35 mm | 0.19 kg |

| PR6426/012-025 | 12 mm | 25 mm | 0.13 kg |

| PR6426/020-040 | 20 mm | 40 mm | 0.21 kg |

Excellent PLC

Excellent PLC