| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

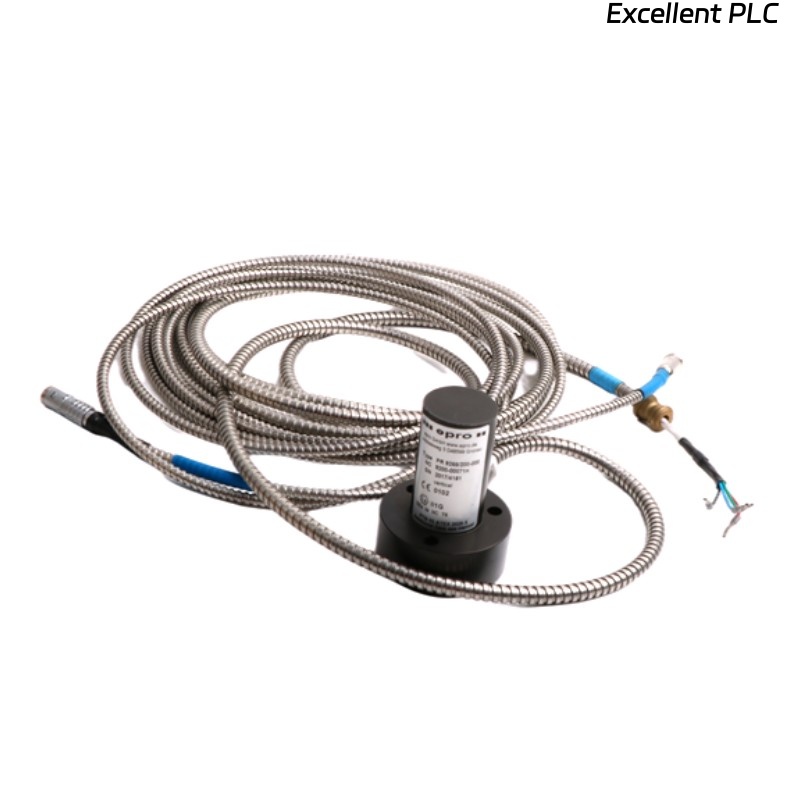

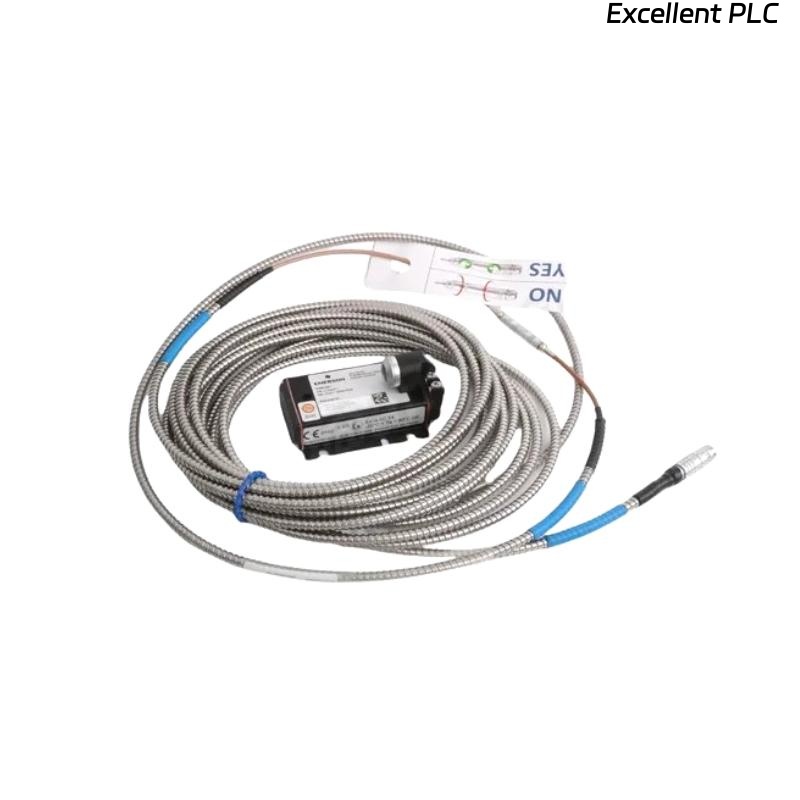

The Epro PR6423/000-040 Eddy-Current Sensor is a high-performance proximity probe designed for precise, non-contact measurement of shaft displacement and vibration in rotating machinery. Utilizing the eddy-current principle, the sensor detects changes in the distance between the probe tip and the conductive surface of a rotating shaft, enabling accurate monitoring of machinery conditions such as unbalance, misalignment, and bearing wear.

Product Advantages

-

High Measurement Accuracy – Provides precise non-contact displacement measurement with excellent linearity.

-

Robust Construction – Designed to operate reliably in harsh environments, including high temperatures and vibration zones.

-

Compact Design – The 8 mm sensor head allows for installation in tight spaces without compromising performance.

-

Long-Term Stability – Ensures consistent performance over time with minimal drift.

-

Wide Compatibility – Works seamlessly with various Epro monitoring systems and other standard proximity monitors.

-

Corrosion-Resistant Material – Ensures durability even in chemically aggressive atmospheres.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | PR6423/000-040 |

| Measuring Principle | Eddy-current displacement measurement |

| Sensor Head Diameter | 8 mm |

| Nominal Measuring Range | 2 mm |

| Frequency Range | DC to 10 kHz |

| Linear Range | 0.2 – 2.0 mm |

| Supply Voltage | -24 V DC (via monitoring system) |

| Sensitivity | 7.87 mV/μm (typical) |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Probe Material | Stainless steel |

| Cable Length | Standard 5 m (custom lengths available) |

| Connector Type | Coaxial connector, compatible with CON041 |

| Weight | 0.1 kg |

| Protection Class | IP67 |

Product Applications

-

Steam and gas turbines

-

Compressors and blowers

-

Electric motors and generators

-

Pumps and gearboxes

-

Bearing and shaft vibration monitoring

-

Turbine supervisory instrumentation systems

Product Advantages in Use

-

Real-Time Monitoring – Provides continuous and accurate data for machinery protection systems.

-

Flexible Installation – Compatible with different mounting configurations and cable lengths.

-

Enhanced Equipment Safety – Detects critical mechanical deviations before failure occurs.

-

Reduced Maintenance Costs – Supports predictive maintenance by identifying early vibration patterns.

-

Proven Reliability – Tested and used globally in high-performance machinery.

FAQ

Q1: What is the operating temperature range for the PR6423/000-040 sensor?

A1: The sensor can operate reliably within a temperature range of -35°C to +180°C.

Q2: What is the standard output sensitivity of this sensor?

A2: The typical sensitivity is approximately 7.87 mV per micrometer of displacement.

Q3: Which monitoring system is compatible with the PR6423/000-040 sensor?

A3: It is fully compatible with Epro CON041 and other related Epro signal conditioning units.

Q4: What is the nominal measuring range of the PR6423/000-040?

A4: The nominal measuring range is 2 mm, allowing accurate detection of small displacements.

Q5: What type of signal output does the sensor provide?

A5: The sensor provides an analog voltage output proportional to the shaft displacement.

Q6: How is the sensor connected to the monitoring system?

A6: It uses a coaxial cable with a matching connector that ensures low noise and high signal integrity.

Q7: Can the PR6423/000-040 be used in high-vibration environments?

A7: Yes, the sensor is designed for heavy industrial use and can perform reliably under high vibration.

Q8: What materials are used in the construction of the probe?

A8: The probe is made of corrosion-resistant stainless steel to ensure durability in harsh environments.

Q9: What is the recommended installation distance from the target surface?

A9: The recommended gap between the probe tip and target surface should be within 0.2–2.0 mm.

Q10: Is the PR6423/000-040 sensor suitable for hazardous area installations?

A10: Yes, specific variants of this model are certified for use in hazardous areas when paired with the appropriate signal converter.

Related or Same-Series Models

| Model | Description | Measuring Range | Sensor Head Diameter | Cable Length |

|---|---|---|---|---|

| PR6423/000-010 | Eddy-current sensor, standard version | 2 mm | 8 mm | 5 m |

| PR6423/002-030 | High-temperature version | 2 mm | 8 mm | 5 m |

| PR6423/003-000 | Extended cable version | 2 mm | 8 mm | 9 m |

| PR6423/010-040 | Heavy-duty type | 2 mm | 8 mm | 5 m |

| PR6423/012-030 | Explosion-proof type | 2 mm | 8 mm | 5 m |

| PR6423/015-000 | Short probe variant | 2 mm | 8 mm | 3 m |

Other Popular Models from Epro

| Model | Description | Application | Output Type |

|---|---|---|---|

| PR6424/000-030 | Eddy-current sensor | Shaft vibration monitoring | Voltage output |

| PR6425/010-140 | Proximity probe | Turbine supervision | Voltage output |

| PR6426/000-030 | Displacement sensor | Generator monitoring | Voltage output |

| CON041 | Signal converter for PR642x series | Condition monitoring | Current/Voltage |

| CON021 | Monitoring system module | Machinery protection | Analog signal |

| PR9268/203-000 | Speed and vibration sensor | Turbomachinery | Frequency output |

Excellent PLC

Excellent PLC