| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

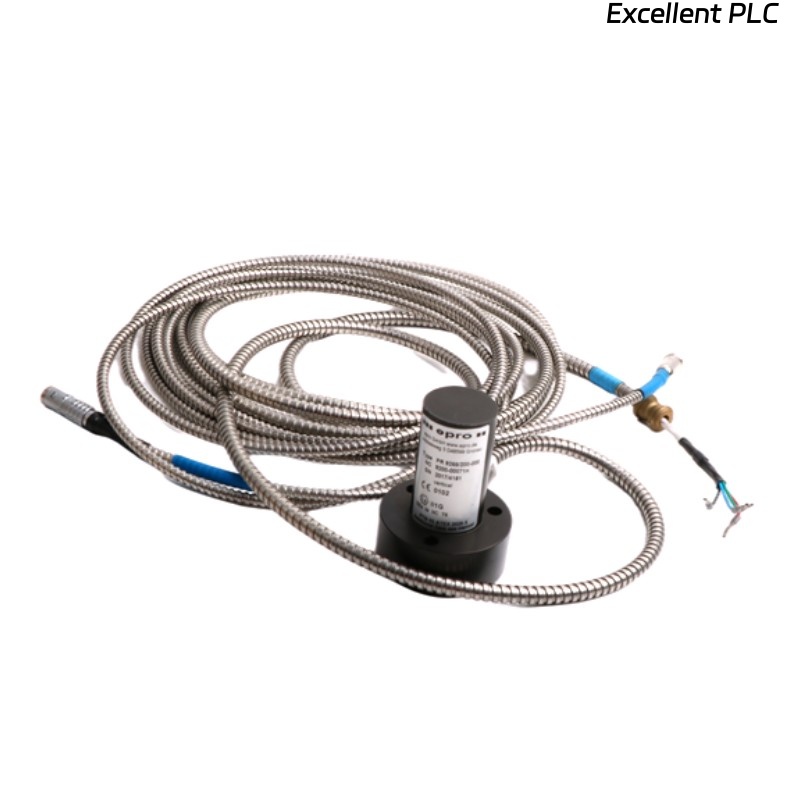

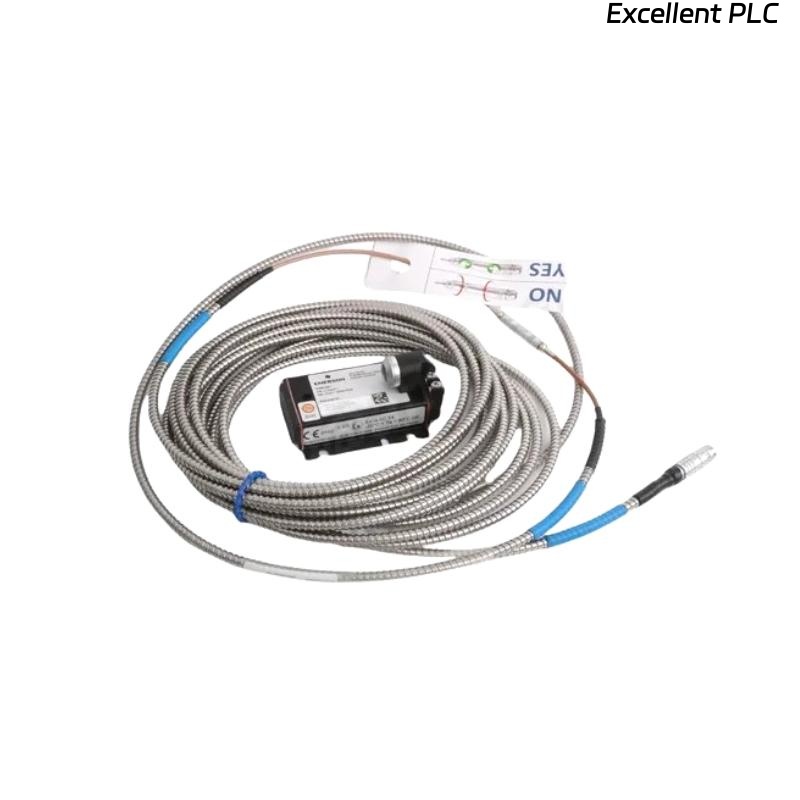

Product Introduction

The Epro PR6423/001-010 Eddy-Current Sensor is a high-performance proximity sensor designed for precise, non-contact measurement of shaft vibration, displacement, and position in rotating machinery. Utilizing advanced eddy-current technology, it provides accurate and reliable signal detection in harsh industrial environments. The sensor is typically paired with Epro’s signal conditioners or monitoring systems to deliver dependable data for machine protection and condition monitoring applications.

Product Advantages

-

High Precision Measurement: Offers excellent accuracy and linearity for monitoring shaft displacement and vibration in critical rotating machinery.

-

Robust Construction: Designed for demanding environments with superior resistance to temperature changes, oil, and vibration.

-

Non-Contact Sensing: Eliminates mechanical wear, ensuring longer service life and stable operation.

-

Easy Integration: Compatible with a wide range of Epro proximity probes and monitoring systems.

-

High Frequency Response: Suitable for fast-moving machinery and dynamic measurement applications.

-

Reliable Performance: Proven reliability in turbines, compressors, and other heavy-duty machinery.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Epro PR6423/001-010 |

| Sensor Type | Eddy-Current Proximity Sensor |

| Measurement Principle | Non-contact eddy-current displacement measurement |

| Sensor Head Diameter | 8 mm |

| Nominal Measuring Range | 2 mm |

| Frequency Range | DC to 20 kHz |

| Sensitivity | 8 mV/µm (nominal) |

| Output Signal | Voltage proportional to distance |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Weight | 0.1 kg |

| Cable Length | Typically 5 m or 9 m (depending on version) |

| Housing Material | Stainless steel |

| Protection Class | IP67 |

| Compatible Systems | Epro PR6424, PR6426, and MMS 6000 Series |

| Mounting Thread | M8 x 1 |

| Power Supply | Through signal conditioner |

| Response Time | <1 ms |

Product Applications

-

Steam and gas turbines

-

Compressors and expanders

-

Generators and motors

-

Gearboxes and pumps

-

Machine condition monitoring systems

-

Bearing vibration and shaft position analysis

Product Advantages in Application

-

Enhanced Equipment Safety: Prevents catastrophic failures by providing early detection of abnormal vibrations.

-

Improved Maintenance Efficiency: Enables condition-based maintenance instead of scheduled servicing.

-

Reduced Downtime: Real-time monitoring ensures rapid response to machine anomalies.

-

Versatility: Suitable for various machine types and compatible with multiple monitoring systems.

FAQ

Q1: What type of signal does the PR6423/001-010 sensor output?

A1: The sensor provides a voltage signal that is directly proportional to the distance between the sensor tip and the target surface.

Q2: Which signal conditioners are compatible with this sensor?

A2: The PR6423/001-010 is compatible with Epro signal conditioners such as PR6424 and PR6426, as well as systems in the MMS 6000 series.

Q3: What is the typical linear measuring range for this model?

A3: The typical linear measuring range is around 2 mm, depending on the target material and calibration.

Q4: What type of target material is recommended for accurate calibration?

A4: The sensor is typically calibrated for steel (AISI 4140) targets to ensure high measurement accuracy.

Q5: How is the sensor connected to the monitoring system?

A5: It is connected via coaxial cable to a signal conditioner, which then interfaces with the monitoring or control system.

Q6: Can the PR6423/001-010 operate in high-temperature environments?

A6: Yes, the sensor is designed to operate reliably up to +180°C ambient temperature.

Q7: What is the frequency response capability of this sensor?

A7: The PR6423/001-010 offers a frequency response from DC up to approximately 20 kHz, suitable for dynamic applications.

Q8: Does the sensor require calibration during installation?

A8: Calibration is recommended during installation to match the target material and ensure accurate displacement readings.

Q9: Can the sensor detect both static and dynamic displacements?

A9: Yes, it measures both static position changes and dynamic vibration displacements accurately.

Q10: Is the PR6423/001-010 resistant to industrial contaminants such as oil or moisture?

A10: Yes, with its IP67 protection class and stainless-steel body, it is resistant to oil, dust, and moisture, ensuring stable operation in harsh environments.

Related or Same-Series Models

| Model | Description | Measuring Range | Sensor Head Diameter | Compatible System |

|---|---|---|---|---|

| PR6423/002-010 | Eddy-Current Sensor | 2 mm | 8 mm | PR6424 / MMS 6000 |

| PR6423/003-010 | Proximity Probe | 2 mm | 8 mm | PR6426 / MMS 6000 |

| PR6423/005-010 | High-Temperature Sensor | 2 mm | 8 mm | PR6426 / MMS 6000 |

| PR6423/006-010 | Standard Probe | 2 mm | 8 mm | PR6424 / MMS 6000 |

| PR6423/007-010 | Extended Range Sensor | 4 mm | 8 mm | PR6424 / MMS 6000 |

| PR6423/010-010 | Compact Design Probe | 2 mm | 8 mm | PR6426 / MMS 6000 |

Popular Models from the Same Brand

| Model | Description | Sensor Type | Measuring Range | Application |

|---|---|---|---|---|

| PR6424/000-030 | Eddy-Current Sensor | Proximity | 2 mm | Shaft vibration monitoring |

| PR6426/000-030 | Proximity Sensor | Eddy-current | 4 mm | Turbine monitoring |

| PR9268/203-000 | Vibration Transducer | Piezoelectric | – | Machinery diagnostics |

| PR9268/205-000 | Velocity Sensor | Electrodynamic | – | Condition monitoring |

| PR9376/010-000 | Signal Converter | Electronic Module | – | Signal conditioning |

| MMS 6001 | Monitoring Module | Control & Protection | – | Vibration monitoring |

| PR9200/001-000 | Speed Sensor | Inductive | – | Rotational speed sensing |

| PR6410/010-000 | Proximity Probe | Eddy-current | 2 mm | Rotor displacement measurement |

Excellent PLC

Excellent PLC