| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

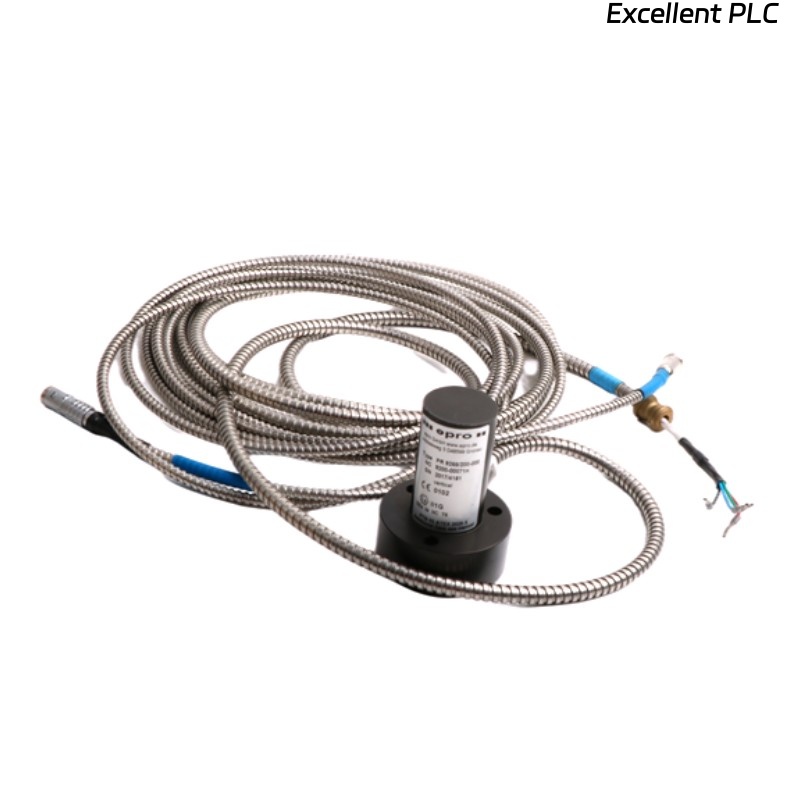

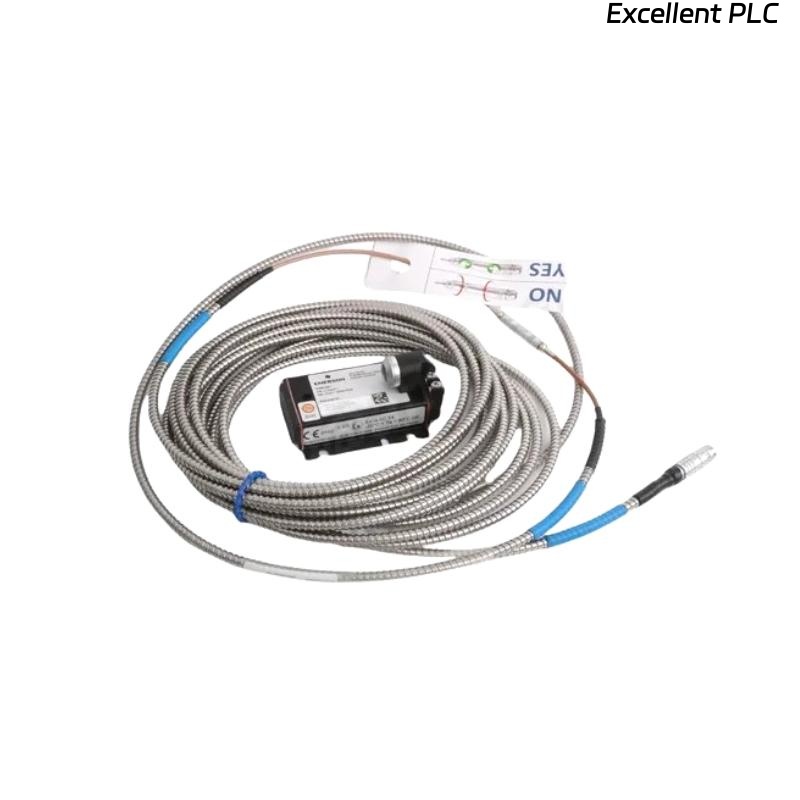

The Epro PR6423/003-131+CON041 8mm Eddy-Current Sensor is a precision vibration and displacement measuring sensor designed for critical rotating machinery applications. Engineered by Epro, a trusted name in industrial condition monitoring, this sensor provides highly accurate, non-contact measurements of shaft vibration and position. It is widely used in turbines, compressors, pumps, and generators where precise monitoring is essential to ensure operational reliability and prevent unplanned shutdowns.

Product Advantages

-

High Precision Measurement: Offers excellent linearity and repeatability for accurate shaft displacement readings.

-

Non-Contact Sensing: Ensures no mechanical wear and enables continuous monitoring of rotating parts.

-

High Environmental Resistance: Works reliably under high temperatures, oil contamination, and vibration conditions.

-

Strong Electromagnetic Shielding: Provides stable operation in electrically noisy environments.

-

Compatible with Epro Monitoring Systems: Seamlessly integrates with Epro CON and MMS series systems.

-

Durable Stainless-Steel Construction: Guarantees long-term stability and corrosion resistance in industrial environments.

Technical Specifications

| Parameter | Description |

|---|---|

| Model Number | PR6423/003-131+CON041 |

| Sensor Type | Eddy-Current Displacement Sensor |

| Sensor Head Diameter | 8 mm |

| Measuring Range | ±2 mm (typical) |

| Sensitivity | 8 mV/µm (nominal) |

| Linearity | ±1% of full-scale output |

| Operating Temperature Range | -35°C to +180°C (sensor only) |

| Frequency Range | DC to 10 kHz |

| Supply Voltage | ±15 V DC |

| Output Signal | Voltage signal (proportional to displacement) |

| Connection Type | With CON041 converter module |

| Housing Material | Stainless Steel |

| Cable Length | Standard 5 m (customizable up to 10 m) |

| Protection Rating | IP67 |

| Weight | 0.22 kg |

Product Applications

-

Steam and gas turbines in power generation plants

-

Centrifugal and axial compressors in oil & gas facilities

-

Industrial pumps and motors in process industries

-

Gearboxes, blowers, and fans in manufacturing operations

-

Bearing and shaft vibration monitoring in heavy-duty equipment

-

Integration with online condition monitoring systems such as Epro MMS6000

Product Advantages in Application

When used in machinery protection systems, this sensor provides continuous, real-time measurement of shaft movement. The data collected allows predictive maintenance teams to identify imbalance, misalignment, or bearing issues before they escalate. The sensor’s ability to operate in contaminated environments ensures reliable performance even when exposed to oil film or metallic particles, which are common in turbine and compressor housings.

FAQ

Q1: What type of output does the PR6423/003-131+CON041 provide?

A1: The sensor provides a voltage output signal proportional to the measured displacement, typically in the range of millivolts per micron.

Q2: Is the sensor compatible with other Epro CON modules?

A2: Yes, it is compatible with various Epro CON series converters, including CON041, CON042, and CON021, depending on system requirements.

Q3: How is the calibration of this sensor performed?

A3: Calibration is typically carried out using a micrometer setup under controlled conditions to ensure accurate linear response within the specified measuring range.

Q4: What is the typical frequency response of the sensor?

A4: The sensor supports a frequency range from DC up to 10 kHz, suitable for dynamic vibration and displacement measurements.

Q5: How should the sensor be mounted for optimal accuracy?

A5: It should be installed perpendicular to the target surface with the correct initial gap (nominal 2 mm) for linear output response.

Q6: Can this sensor be used in oil-lubricated machinery?

A6: Yes, it is specifically designed to perform accurately in oil-rich and contaminated environments.

Q7: What cable length options are available?

A7: Standard cable length is 5 meters, but customized lengths up to 10 meters are available upon request.

Q8: Does temperature variation affect measurement accuracy?

A8: The sensor compensates for temperature drift through internal design, maintaining stable readings across its operating temperature range.

Q9: Is the PR6423/003-131+CON041 suitable for monitoring axial displacement?

A9: Yes, it can measure both radial and axial displacement depending on installation orientation.

Q10: How does the CON041 converter contribute to system performance?

A10: The CON041 module processes the sensor’s signal, providing precise conditioning and linearization for accurate data output compatible with Epro monitoring systems.

Related or Same-Series Models

| Model Number | Description |

|---|---|

| PR6423/000-030 | 8mm Eddy-Current Sensor with standard configuration |

| PR6423/001-010 | High-temperature version for turbine monitoring |

| PR6423/002-000 | Sensor for short-distance vibration measurement |

| PR6423/004-030 | Extended range model for heavy machinery |

| PR6423/005-031 | Low-frequency optimized version |

| PR6423/010-000 | Advanced sensitivity type for precision machinery |

Popular Models from the Same Brand

| Model Number | Description | Sensor Type | Measuring Range | Weight |

|---|---|---|---|---|

| PR6423/000-040 | Eddy-current sensor for standard vibration use | Eddy-Current Displacement | ±2 mm | 0.22 kg |

| PR6424/010-000 | 5 mm probe for compact installation | Eddy-Current Displacement | ±1 mm | 0.18 kg |

| PR6426/000-030 | 11 mm probe for long-range measurements | Eddy-Current Displacement | ±3 mm | 0.28 kg |

| PR6425/010-140 | High-temp sensor with enhanced thermal shielding | Eddy-Current Displacement | ±2 mm | 0.25 kg |

| PR9268/203-000 | Vibration monitoring sensor with advanced accuracy | Proximity/Vibration Sensor | ±1 mm | 0.20 kg |

| PR6423/003-040 | 8 mm sensor with alternate CON module option | Eddy-Current Displacement | ±2 mm | 0.22 kg |

Excellent PLC

Excellent PLC