| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

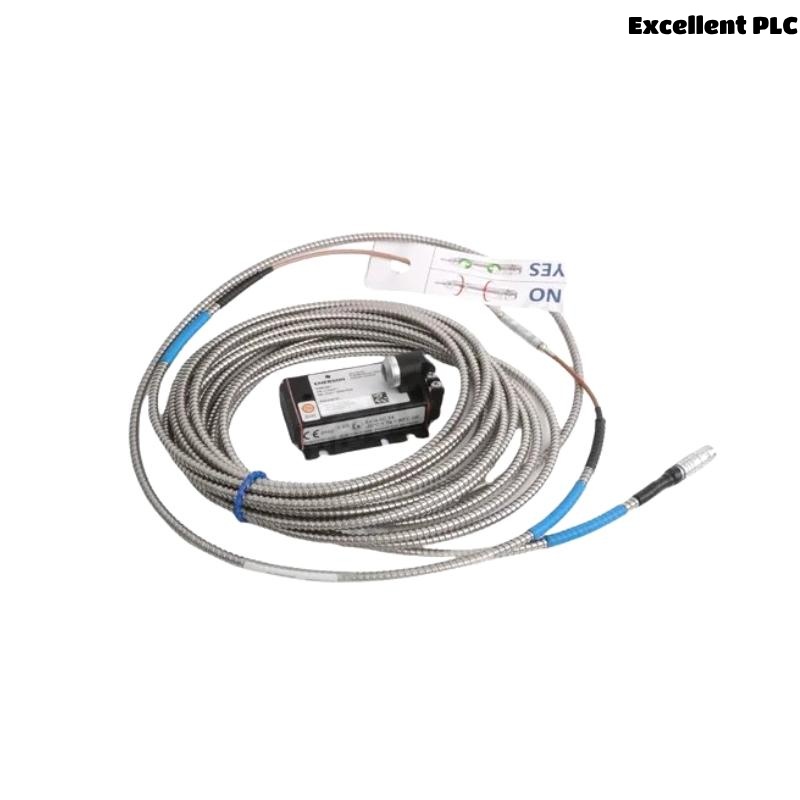

The Epro PR6423/004-000 is a high-performance non-contact eddy current displacement sensor, engineered specifically for critical machinery monitoring in industrial environments. Designed and manufactured by Epro (now under Emerson Process Management), this sensor forms part of a modular system intended for real-time monitoring of shaft displacement, vibration, and positioning of rotating equipment.

Featuring an 8mm probe diameter, the PR6423/004-000 offers excellent linearity, wide frequency response, and durability in harsh operating conditions. When used in conjunction with Epro’s CON0xx converters (such as CON021 or CON041), the sensor provides a complete measurement chain capable of withstanding high temperatures, contamination, and electromagnetic interference.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6423/004-000 |

| Sensor Type | Eddy Current Displacement Probe |

| Measuring Principle | Non-contact electromagnetic induction (Eddy Current) |

| Measuring Range | 0 – 2.0 mm (Nominal) |

| Linear Range | ±1.0 mm |

| Sensor Head Diameter | 8 mm |

| Mounting Thread | M10 x 1 (standard); other threads available on request |

| Cable Length | Supplied separately; typically used with 5 m or 10 m cable |

| Frequency Response | DC to 10 kHz |

| Sensitivity | Approx. 7.87 mV/µm (±5%) |

| Temperature Range (Probe) | -35°C to +180°C |

| Environmental Rating | IP65 |

| Target Material | Ferromagnetic metals (e.g., AISI 4140, 4340) |

| Compliance Certifications | CE, ATEX compliant versions available |

| Weight | 0.1 kg |

| Installation | Axial or radial depending on vibration vector |

Product Applications

The PR6423/004-000 is built for demanding applications in critical rotating equipment. It is a preferred choice for:

-

Steam and Gas Turbines – Shaft displacement, vibration, and thermal expansion monitoring.

-

Centrifugal Compressors – Radial and axial position tracking for high-speed rotors.

-

Pumps and Motors – Real-time diagnostics to detect imbalance, misalignment, and bearing wear.

-

Gearboxes and Industrial Drives – Early fault detection in mechanical power transmission systems.

-

OEM Machinery – Integrated into machinery by equipment manufacturers for condition monitoring.

Its robust construction and temperature tolerance make it ideal for installation in hazardous, high-vibration, and oil-contaminated environments commonly found in petrochemical, power generation, and heavy manufacturing sectors.

Product Advantages

-

High-Temperature Resilience: Operates up to +180°C without signal degradation.

-

Excellent Linearity and Sensitivity: Ensures precise, stable output across the full measuring range.

-

Non-Contact Design: Minimizes mechanical wear, extending service life and reducing maintenance needs.

-

Modular Compatibility: Works with various Epro converter models (e.g., CON021, CON041).

-

Rugged Design: IP65-rated, making it suitable for dusty, wet, or contaminated environments.

-

Customizable: Available with optional cable lengths, thread types, and certifications.

-

CE and ATEX Compliance: Safe for use in industrial and potentially explosive zones.

Frequently Asked Questions (FAQ)

-

What is the measuring principle used in the PR6423/004-000?

It utilizes the eddy current principle to detect non-contact displacement in conductive materials. -

Can the PR6423/004-000 be used in high-temperature environments?

Yes, the probe is designed to function reliably in environments up to +180°C. -

Is the probe compatible with all Epro converters?

It is compatible with most, including CON021 and CON041, depending on signal conditioning requirements. -

What is the standard thread size for mounting this probe?

It comes with an M10x1 thread; other thread sizes can be requested. -

Does the sensor require recalibration in the field?

No, factory calibration is provided and field recalibration is generally unnecessary unless conditions change. -

What is the IP rating of the sensor?

The probe is rated IP65, offering solid protection against dust and water ingress. -

How long is the probe cable?

The cable is sold separately, usually in 5 m or 10 m lengths. -

What are the main differences between the PR6423/004-000 and PR6423/002-030?

While both are 8mm probes, the PR6423/004-000 is optimized for higher accuracy and cleaner signal output in lower-noise applications. -

Can this probe be installed horizontally and vertically?

Yes, orientation depends on the axis of the vibration or displacement you wish to monitor. -

What materials are recommended as targets for measurement?

Best performance is achieved with ferromagnetic metals such as AISI 4140 and 4340.

Related Models from the Same Series (Epro PR6423)

| Model Number | Description | Probe Diameter | Cable Length | Use Case |

|---|---|---|---|---|

| PR6423/000-000 | Standard eddy current probe | 8 mm | Configurable | General purpose |

| PR6423/002-030 | Probe with high-temp CON021 converter | 8 mm | 3 m | Turbine shaft monitoring |

| PR6423/003-010 | Extended range version | 8 mm | 10 m | Wide displacement range monitoring |

| PR6423/005-010 | ATEX-certified probe with 10m cable | 8 mm | 10 m | Explosive environments |

| PR6423/012-100 | Compact-length sensor | 8 mm | 1 m | Tight space installations |

| PR6423/011-010 | Standard sensor matched with CON021 | 8 mm | 10 m | Compressors, pumps, general equipment |

Popular Models from the Same Brand (Epro / Emerson)

| Model Number | Description | Product Type | Typical Application |

|---|---|---|---|

| PR6424/010-140 | High-temperature eddy current probe | 5 mm sensor | Gas turbines, extreme environments |

| PR9268/203-000 | Velocity vibration sensor | Seismic sensor | Industrial rotating machinery |

| MMS3120/022-100 | Monitoring rack with vibration channels | Monitoring system | PR6423/PR6424 integration |

| CON021 | Standard converter for eddy current probes | Signal conditioner | Works with PR6423/PR6424 series |

| TQ403 | Keyphasor or phase trigger module | Timing module | Shaft phase reference |

| MMS6110 | Compact vibration and process signal monitoring | Monitoring system | Compact plant installations |

Excellent PLC

Excellent PLC