| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

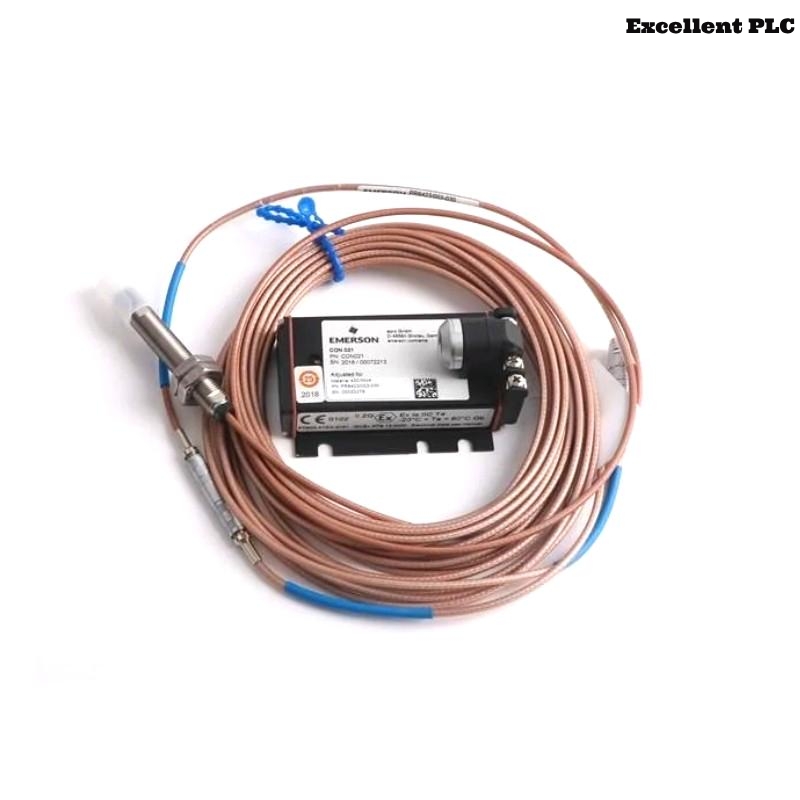

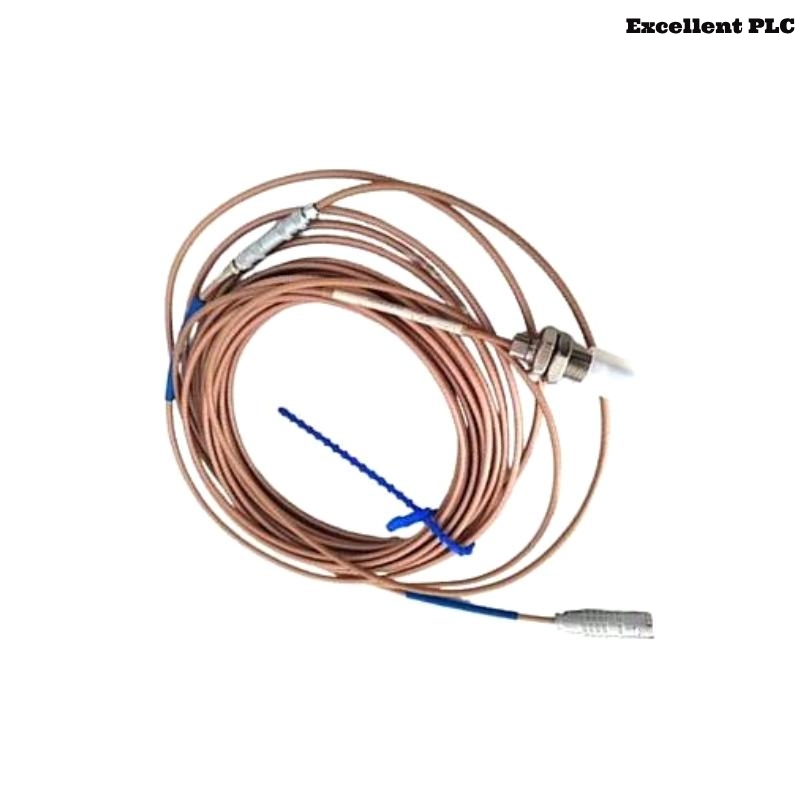

Product Introduction

The Epro PR6423/00H-030 8mm Eddy Current Sensor is a high-performance, non-contact displacement sensor specifically designed for monitoring critical parameters in industrial machinery. This sensor is particularly well-suited for detecting radial and axial displacement, as well as position changes in rotating equipment, such as turbines, motors, compressors, and pumps. It offers high sensitivity, fast response time, and excellent accuracy for shaft vibration monitoring and rotor alignment detection.

Product Specifications

| Parameter | Description |

|---|---|

| Model | PR6423/00H-030 |

| Measurement Range | 2 mm (80 mils) |

| Initial Air Gap | 0.5 mm (20 mils) |

| Sensitivity | 8 V/mm (203.2 mV/mil) ±5% @ 0 to 45°C |

| Frequency Range (-3 dB) | 0 to 20,000 Hz |

| Rise Time | <15 µs |

| Operating Temperature | -35°C to +85°C |

| Storage Temperature | -40°C to +100°C |

| Protection Class | IP20 |

| Housing Material | PA 6.6 |

| Sensor Head Diameter | 8 mm |

| Weight (Sensor) | 0.1 kg |

| Power Supply | -23V to -32V DC |

| Output Signal | Voltage output (e.g., -2V to -18V) |

| Mounting | DIN rail (Converter) |

| Certifications | CE, ATEX, IECEx, CSA |

| Measurement Type | Eddy current, non-contact displacement measurement |

Applications

The Epro PR6423/00H-030 8mm Eddy Current Sensor is used across various industries where high-precision measurements are crucial for operational safety and efficiency:

-

Turbine Monitoring: Ideal for measuring shaft displacement and eccentricity in steam, gas, or hydro turbines.

-

Compressor Condition Monitoring: Ensures accurate alignment and vibration measurements to prevent failure in compressors.

-

Pump & Fan Protection: Detects imbalances and misalignments in pumps and fans, reducing the risk of mechanical failures.

-

Gearbox Diagnostics: Measures rotational displacement to monitor gear and bearing health.

-

Rotating Machinery Performance: Provides critical feedback on the status of rotating machinery, ensuring safe and efficient operation.

Product Advantages

-

Non-Contact Technology: This sensor eliminates mechanical wear and tear by using eddy current technology, ensuring long-term performance and reduced maintenance.

-

High Sensitivity: The sensor’s sensitivity of 8 V/mm ensures it can detect even small displacements, providing accurate measurements for critical systems.

-

Wide Frequency Range: With a frequency range of 0 to 20,000 Hz, it can monitor both low and high-frequency vibrations, making it suitable for a wide array of applications.

-

Compact and Robust: The sensor’s small diameter (8mm) and rugged construction make it highly reliable in harsh industrial environments.

-

Easy Integration: The sensor can be easily integrated into existing monitoring systems via its voltage output.

-

Wide Temperature Range: With an operating range from -35°C to +85°C, the sensor can be used in a variety of temperature conditions.

Frequently Asked Questions (FAQ)

-

What is the primary function of the PR6423/00H-030 sensor?

The sensor measures radial and axial displacement, position, and vibration in rotating machinery, helping prevent failures due to misalignment or eccentricity. -

How accurate is the displacement measurement?

The sensor offers high accuracy, with a sensitivity of 8 V/mm (203.2 mV/mil), ensuring precise readings for critical applications. -

Can the sensor operate in high-temperature environments?

Yes, it is capable of operating in temperatures from -35°C to +85°C, making it suitable for a variety of industrial applications. -

What is the rise time of the sensor?

The sensor has a rise time of less than 15 µs, enabling it to capture rapid changes in displacement. -

What is the protection class of the sensor?

The sensor has an IP20 protection rating, which makes it suitable for environments where it is not exposed to direct water or dust ingress. -

What kind of output signal does the sensor provide?

The sensor provides a voltage output, typically in the range of -2V to -18V, for easy integration with monitoring systems. -

How is the sensor mounted?

The sensor is designed to be mounted close to the rotating shaft, while the converter unit is typically mounted on a DIN rail. -

What are the sensor’s power requirements?

The sensor requires a DC power supply ranging from -23V to -32V for proper operation. -

Is the sensor suitable for hazardous environments?

Yes, the sensor meets ATEX and IECEx certifications, making it suitable for use in hazardous locations. -

What is the weight of the sensor?

The sensor weighs 0.1 kg, making it lightweight and easy to install.

Related Models (Same Series or Functionality)

| Model Number | Description |

|---|---|

| PR6423/001-110 | 8mm sensor with longer cable length |

| PR6423/00H-031 | Enhanced version with higher temperature tolerance |

| PR6423/003-121 | 8mm sensor with increased frequency range |

| PR6423/002-112 | Similar sensor with alternative mounting options |

| PR6423/004-030 | Compact 8mm sensor for smaller machines |

| PR6423/00H-033 | Extended range sensor for high-speed applications |

Popular Models from Epro (Same Brand)

| Model Number | Description |

|---|---|

| PR6423/002-110 | 8mm sensor with enhanced environmental protection |

| PR6423/00F-040 | High-performance sensor for turbines and high-speed motors |

| PR6423/004-021 | Specially designed for automotive and industrial applications |

| PR6423/005-120 | Vibration sensor for gearbox monitoring |

| PR6423/006-025 | 8mm sensor with extended measurement range |

| PR6423/00K-121 | Sensor with enhanced sensitivity for precision applications |

Excellent PLC

Excellent PLC