| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

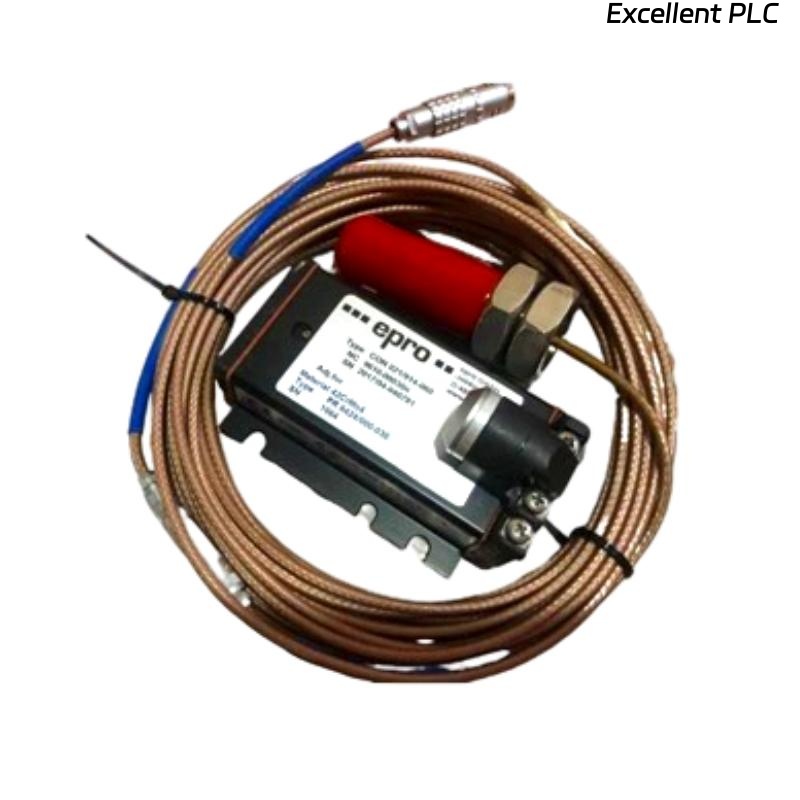

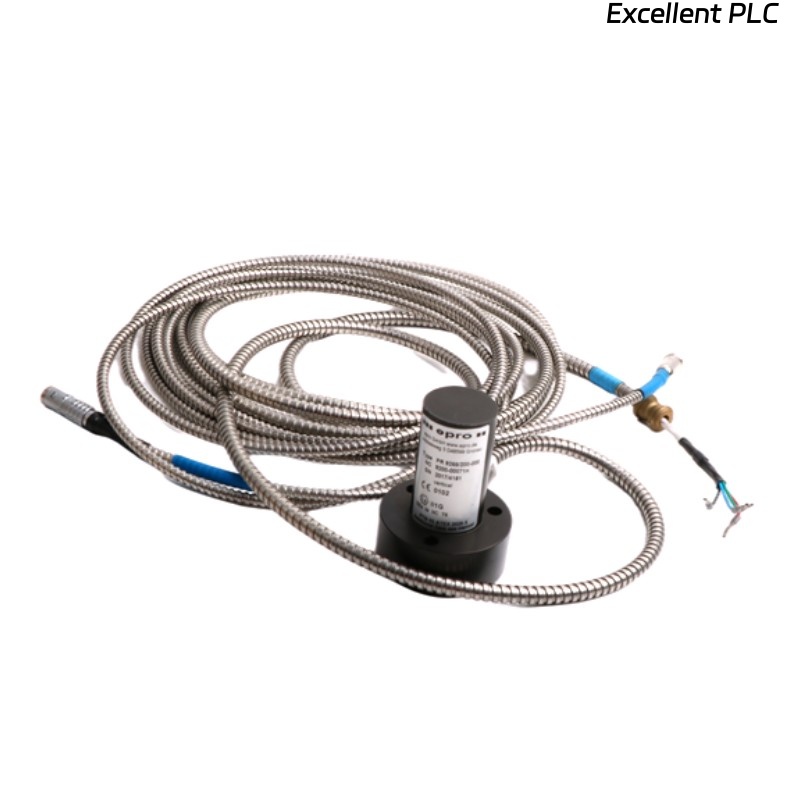

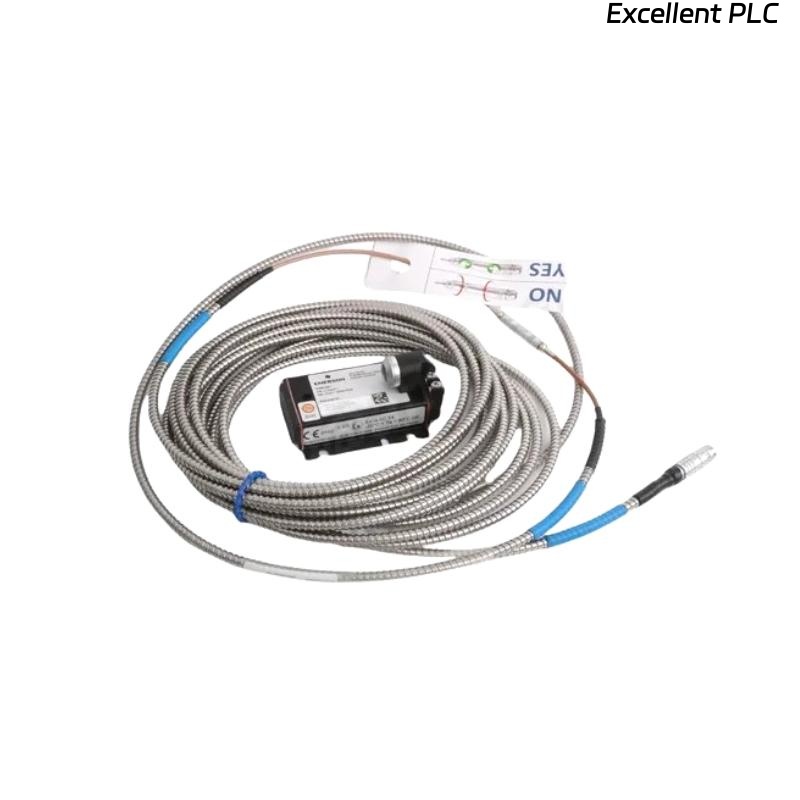

The Epro PR6423/00R-030 is a high-performance eddy-current proximity sensor designed for precise and reliable measurement of shaft vibration, position, and displacement in rotating machinery. This 8mm sensor is part of Epro’s advanced vibration monitoring series, known for its accuracy, stability, and robustness under demanding industrial conditions.

Product Advantages

-

High Precision Measurement: Delivers highly accurate vibration and displacement readings for critical machinery protection.

-

Non-Contact Operation: Minimizes wear and maintenance by avoiding mechanical contact with the target surface.

-

Excellent Temperature Stability: Maintains performance consistency across a wide range of operating temperatures.

-

Rugged Construction: Designed with a durable stainless-steel sensor head and robust cable for harsh industrial use.

-

Compatibility: Fully compatible with Epro CON021 and CON041 drivers for flexible system integration.

-

Reliable in Harsh Environments: Resistant to oil, dust, and electromagnetic interference, ensuring long-term reliability.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | PR6423/00R-030 |

| Sensor Type | Eddy-Current Proximity Sensor |

| Sensor Head Diameter | 8 mm |

| Measuring Range | 2 mm (nominal) |

| Frequency Response | Up to 10 kHz |

| Sensitivity | 8 mV/µm (typical) |

| Linearity | ±1% of full scale |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Weight | 0.1 kg |

| Housing Material | Stainless Steel |

| Cable Type | Coaxial, high-temperature resistant |

| Power Supply (via driver) | ±15 V DC |

| Connection Interface | BNC or compatible connector |

| Recommended Driver | Epro CON021, CON041 |

| Protection Rating | IP67 |

Product Applications

-

Steam and Gas Turbines: Monitoring shaft vibration to prevent damage from imbalance or misalignment.

-

Compressors and Pumps: Ensuring smooth operation and detecting bearing wear or shaft movement.

-

Generators and Motors: Used for condition monitoring and predictive maintenance.

-

Gearboxes: Detecting gear mesh anomalies and misalignments.

-

Industrial Process Equipment: Supporting protection systems in petrochemical and power generation plants.

FAQ

Q1: What type of output signal does the PR6423/00R-030 generate?

A1: The sensor provides an analog voltage signal proportional to the gap or displacement, typically 8 mV/µm, depending on the connected driver module.

Q2: Which drivers are compatible with the PR6423/00R-030 sensor?

A2: It is compatible with Epro CON021 and CON041 driver units, ensuring accurate linearization and calibration of the sensor signal.

Q3: How does the sensor maintain accuracy in high-temperature environments?

A3: The sensor is built with temperature-compensated components and high-grade materials that minimize signal drift over a wide temperature range.

Q4: What is the frequency response range of the PR6423/00R-030?

A4: It supports frequencies up to approximately 10 kHz, suitable for most high-speed rotating machinery applications.

Q5: Can this sensor detect both static and dynamic shaft movements?

A5: Yes, it can measure both static displacement and dynamic vibration signals, providing full-spectrum monitoring capability.

Q6: What type of target materials can the sensor measure?

A6: It is optimized for conductive targets such as steel, with calibration typically based on AISI 4140 steel surfaces.

Q7: Is the sensor immune to electromagnetic interference (EMI)?

A7: Yes, the sensor features excellent EMI shielding through its coaxial cable design and grounded stainless-steel housing.

Q8: How is the PR6423/00R-030 calibrated?

A8: Calibration is performed using standard calibration sets with the connected driver (CON021 or CON041) according to ISO 10817-1 standards.

Q9: Can multiple PR6423 sensors be used in a single monitoring system?

A9: Yes, multiple sensors can be installed and connected to Epro monitoring racks, allowing multi-channel vibration analysis.

Q10: What is the typical installation distance between the sensor and target surface?

A10: The nominal gap distance is around 1.0 mm, adjustable according to calibration and system configuration.

Related or Same-Series Models

| Model | Description | Sensor Head Diameter | Cable Length |

|---|---|---|---|

| PR6423/00R-010 | Eddy-Current Sensor | 8 mm | 1 m |

| PR6423/00R-020 | Eddy-Current Sensor | 8 mm | 2 m |

| PR6423/00R-040 | Eddy-Current Sensor | 8 mm | 4 m |

| PR6423/00R-050 | Eddy-Current Sensor | 8 mm | 5 m |

| PR6423/10R-030 | High-Temperature Version | 8 mm | 3 m |

| PR6423/12R-030 | Shielded Cable Version | 8 mm | 3 m |

Popular Models from the Same Brand

| Model | Description | Function | Compatible Driver |

|---|---|---|---|

| PR6424/00R-030 | Eddy-Current Sensor (5 mm) | Shaft vibration measurement | CON021 |

| PR6422/00R-010 | Proximity Probe | Position and displacement | CON041 |

| PR9268/203-000 | Vibration Transducer | Velocity measurement | – |

| CON021 | Proximity Driver | Signal conditioning for sensors | – |

| CON041 | Proximity Driver | Dual-channel version for PR6423 series | – |

| PR6425/00R-020 | Proximity Probe (11 mm) | Long-range vibration sensing | CON021 |

Excellent PLC

Excellent PLC