| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

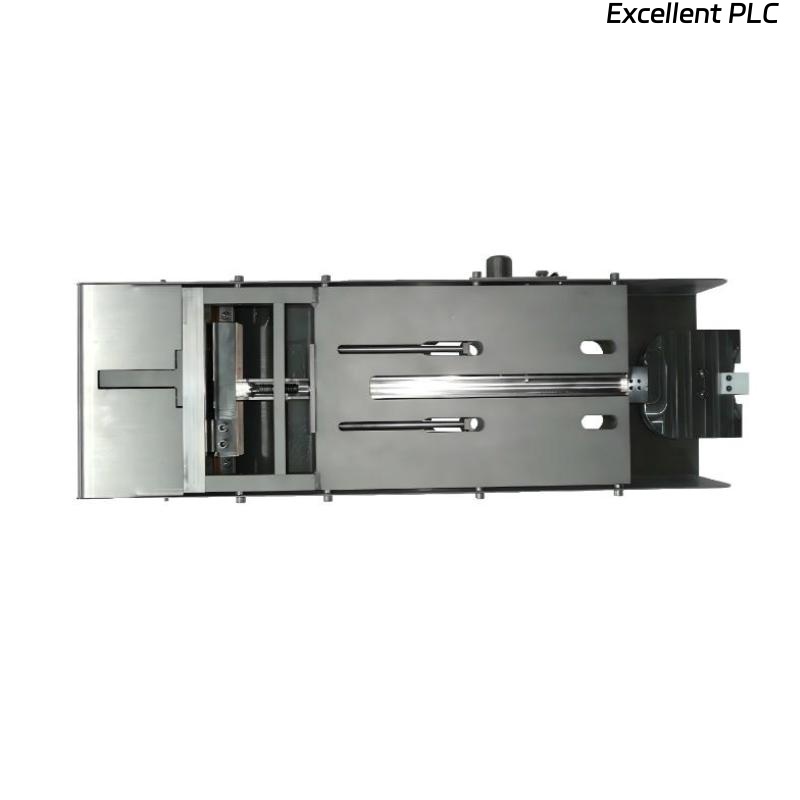

The Epro PR6423/00R-111+CON041 8mm Eddy-Current Sensor is a high-precision proximity sensor designed for continuous, non-contact measurement of shaft vibration and displacement in rotating machinery. It operates on the eddy-current principle, ensuring accurate detection of metallic surface movements even under harsh industrial conditions. This sensor, when used with the CON041 converter, provides a reliable and linear voltage output proportional to the gap distance, making it suitable for critical condition monitoring in turbines, compressors, and motors.

Product Parameters

| Parameter | Description |

|---|---|

| Model | Epro PR6423/00R-111 + CON041 |

| Measurement Principle | Eddy Current (Non-contact displacement measurement) |

| Sensor Head Diameter | 8 mm |

| Weight | 0.22 kg |

| Probe Material | Stainless steel, corrosion-resistant |

| Measuring Range | 2 mm to 4 mm (depending on target material and configuration) |

| Linearity | ±1% of full scale |

| Sensitivity | 7.87 mV/µm (typical with CON041 converter) |

| Operating Temperature | -35°C to +180°C |

| Frequency Response | DC to 10 kHz (-3 dB) |

| Power Supply (via CON041) | ±15 V DC |

| Output Signal | Voltage proportional to distance (0–10 V DC typical) |

| Cable Length | Configurable up to 10 meters |

| Insulation Resistance | >100 MΩ at 500 V DC |

| Protection Class | IP67 (sensor), IP65 (connector) |

| Compliance | API 670 / ISO 10816 vibration monitoring standards |

Product Applications

-

Turbomachinery shaft vibration and position monitoring

-

Compressor bearing gap measurement

-

Generator and motor shaft alignment observation

-

Steam turbine radial displacement detection

-

Pump and fan rotor dynamic behavior analysis

-

Integration with vibration protection and diagnostic systems

Product Advantages

-

High Precision and Stability – Provides highly accurate measurement of shaft displacement and vibration with minimal drift over time.

-

Robust Industrial Design – Resistant to oil, dirt, and high temperatures, ensuring long-term reliability in harsh environments.

-

API 670 Compliant – Fully meets international vibration monitoring standards for critical rotating equipment.

-

Non-Contact Measurement – Eliminates mechanical wear and allows operation without influencing machine dynamics.

-

Excellent Linearity and Sensitivity – Provides consistent signal output for precise condition analysis.

-

Flexible Installation – Compatible with multiple converter types and available in various cable lengths to fit different setups.

-

Low Noise Output – Designed with superior shielding and grounding for stable signal transmission even in high EMI environments.

FAQ

Q1: How does the PR6423/00R-111 sensor detect vibration or displacement?

A1: It operates on the eddy-current principle, generating a magnetic field that induces eddy currents in the metallic target surface. The amplitude of these currents changes with the distance, allowing precise non-contact displacement measurement.

Q2: What type of converter is required with this sensor?

A2: The PR6423/00R-111 is designed to work with the Epro CON041 converter, which linearizes and scales the sensor output for integration into monitoring systems.

Q3: Is the sensor output signal linear across the full range?

A3: Yes, the output is highly linear (±1% typical) across the specified measuring range when properly calibrated with the correct converter.

Q4: Can the sensor be used in high-temperature environments?

A4: Yes, the sensor operates reliably up to +180°C and can be used in thermally demanding applications with appropriate cabling.

Q5: How is electromagnetic interference minimized?

A5: The sensor and cable assembly are fully shielded, and differential signal transmission minimizes noise from external EMI sources.

Q6: Is the PR6423/00R-111 compatible with other monitoring systems?

A6: Yes, it provides an analog voltage output compatible with most industrial condition monitoring and protection systems that accept standard signal inputs.

Q7: What materials are suitable as targets for this sensor?

A7: It is optimized for ferromagnetic materials such as steel or iron but can also measure non-ferromagnetic conductive metals with minor calibration adjustments.

Q8: How is the probe calibrated with the CON041 converter?

A8: Calibration involves setting the nominal gap and verifying linear output across the working range using a reference metallic surface and adjustment tools provided by Epro.

Q9: What is the sensor’s response time to rapid shaft movement?

A9: The sensor features a fast response frequency up to 10 kHz (-3 dB), allowing accurate capture of dynamic shaft behavior.

Q10: Can multiple sensors be installed close to each other without interference?

A10: Yes, but they must be spaced according to Epro’s installation guidelines to prevent cross-coupling between their magnetic fields.

Related Models

| Model | Description | Sensor Diameter | Measuring Range | Operating Temperature |

|---|---|---|---|---|

| PR6423/00R-030 | Eddy-current sensor, standard version | 8 mm | 2–4 mm | -35°C to +180°C |

| PR6423/00R-040 | High-temp variant | 8 mm | 2–4 mm | -35°C to +200°C |

| PR6423/00R-050 | Extended range version | 8 mm | 3–5 mm | -35°C to +180°C |

| PR6423/010-000 | General-purpose proximity probe | 8 mm | 2–4 mm | -35°C to +180°C |

| PR6423/001-010 | Rugged type for compressor monitoring | 8 mm | 2–4 mm | -35°C to +180°C |

| PR6423/000-040 | API 670 certified industrial version | 8 mm | 2–4 mm | -35°C to +180°C |

Popular Models from the Same Brand

| Model | Product Type | Application | Key Feature | Weight |

|---|---|---|---|---|

| PR9268/203-000 | Vibration Transducer | Turbine vibration monitoring | High sensitivity, fast response | 0.35 kg |

| PR6424/000-031 | Eddy Current Sensor | Shaft displacement measurement | 5 mm probe, high accuracy | 0.18 kg |

| PR6425/000-030 | Eddy Current Sensor | Compact machinery | 5 mm probe, short body | 0.15 kg |

| PR6426/000-030 | Eddy Current Sensor | Large rotating machines | 11 mm probe, wide range | 0.25 kg |

| CON021 | Converter | Signal conditioning | Compatible with PR642x sensors | 0.3 kg |

| CON041 | Converter | Linearization unit for PR6423 | High precision voltage output | 0.32 kg |

| MMS6832 | Monitoring Module | Machine protection systems | API 670 compliant | 0.5 kg |

| MMS6110 | Control Module | Turbomachinery diagnostics | Modular design, field-replaceable | 0.48 kg |

Excellent PLC

Excellent PLC