| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

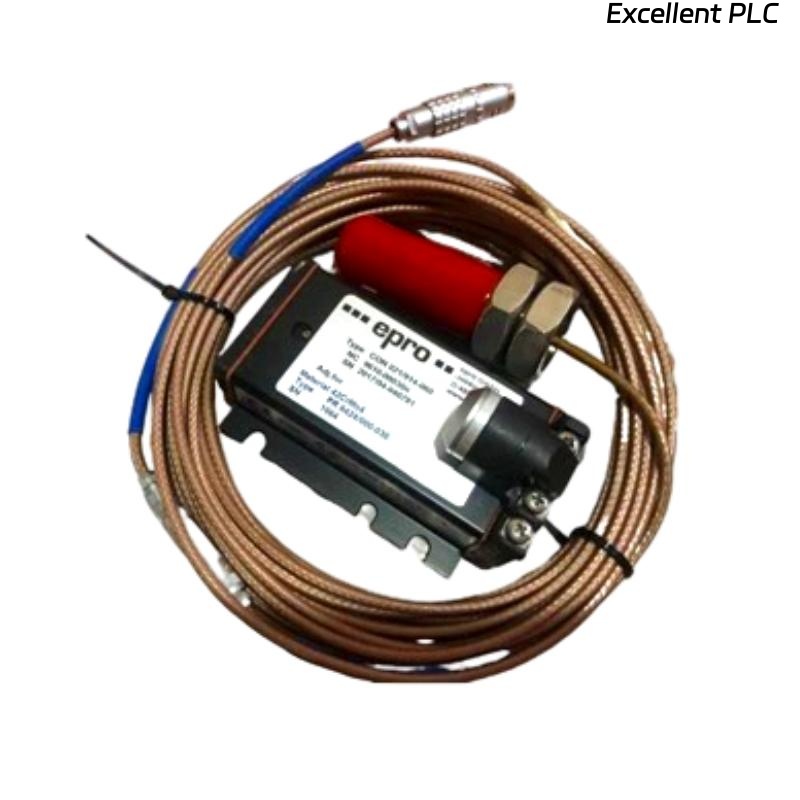

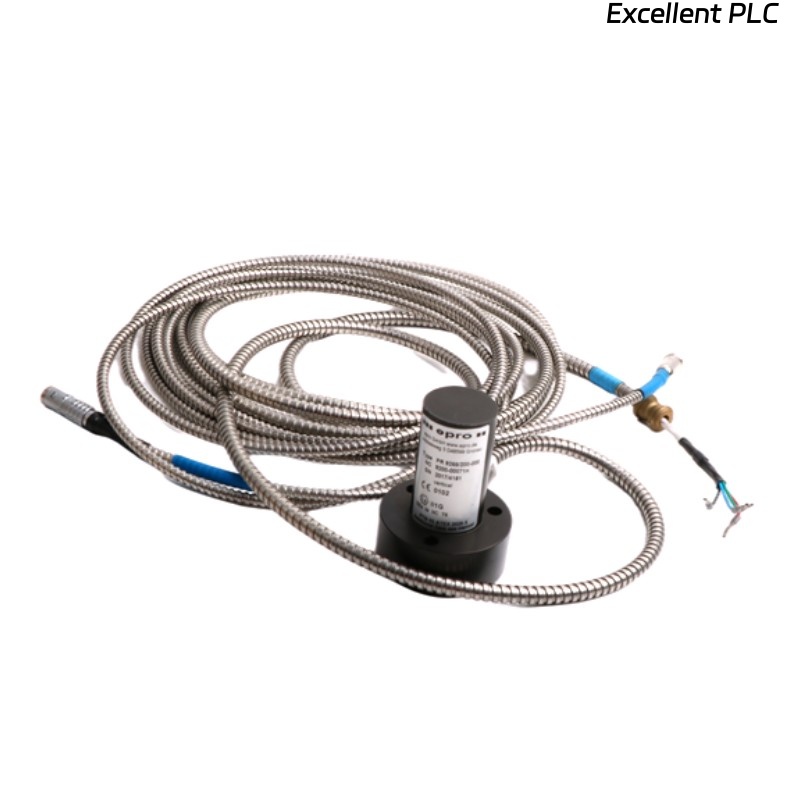

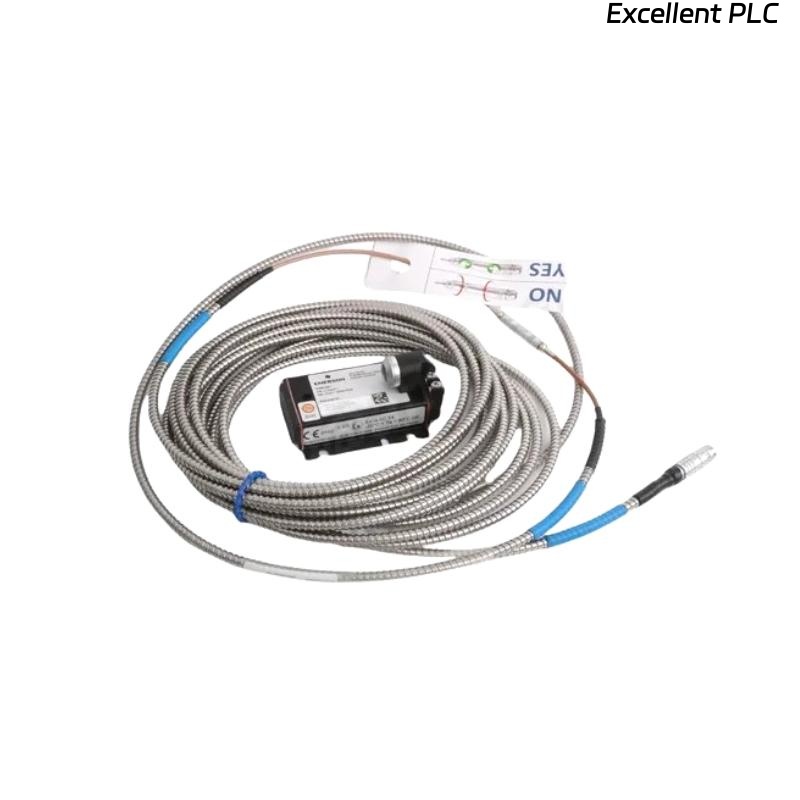

The Epro PR6423/010-000 Eddy-Current Sensor is a precision instrument designed for accurate, contactless measurement of shaft displacement and vibration in rotating machinery. It operates on the eddy-current principle, ensuring high reliability and excellent linearity even in harsh industrial environments. This sensor is typically used with Epro signal conditioners or monitoring systems, such as the Epro MMS series, to provide real-time data for condition monitoring and predictive maintenance.

Product Advantages

-

High Measurement Accuracy: Ensures precise monitoring of shaft displacement and vibration with excellent repeatability.

-

Non-Contact Operation: Enables continuous monitoring without mechanical wear or interference with machine operation.

-

Wide Temperature Range: Capable of reliable performance under extreme environmental conditions.

-

Rugged Construction: Stainless-steel housing provides excellent resistance to mechanical stress, oil, and moisture.

-

Compatibility: Fully compatible with Epro and Vibro-Meter monitoring systems, supporting easy integration into existing setups.

-

Electromagnetic Immunity: Designed to resist electrical noise and interference in heavy industrial settings.

Technical Specifications

| Parameter | Description |

|---|---|

| Sensor Type | Eddy-Current Displacement Sensor |

| Model | PR6423/010-000 |

| Sensor Head Diameter | 8 mm |

| Measurement Range | Up to 2 mm (depending on target material and configuration) |

| Sensitivity | 8 mV/µm (nominal) |

| Frequency Range | DC to 10 kHz |

| Linear Range | ±1 mm |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Power Supply | Supplied via signal conditioner (e.g., Epro CON021) |

| Cable Type | Integrated coaxial cable |

| Cable Length | 5 meters (standard) |

| Housing Material | Stainless Steel |

| Protection Class | IP67 |

| Weight | 0.1 kg |

| Connection Type | BNC or system-specific connector |

| Mounting | Threaded sleeve or bracket installation |

Product Applications

-

Turbomachinery: Monitoring shaft vibration and position in steam and gas turbines.

-

Compressors: Tracking dynamic shaft behavior to prevent bearing or rotor failures.

-

Pumps and Motors: Ensuring smooth operation by measuring rotor displacement.

-

Gearboxes: Detecting shaft misalignment and gear wear early.

-

Generators: Monitoring axial and radial shaft movements for stability and safety.

Product Advantages in Use

-

Enhances system reliability by providing continuous, precise data on shaft motion.

-

Simplifies maintenance scheduling through real-time monitoring data.

-

Increases equipment lifespan by preventing catastrophic failures.

-

Ensures safety compliance in industrial monitoring systems.

-

Allows seamless retrofitting into existing monitoring setups with standard Epro interfaces.

FAQ

Q1: What principle does the PR6423/010-000 sensor operate on?

A1: It operates on the eddy-current principle, where a magnetic field interacts with a conductive target to measure displacement without contact.

Q2: What type of signal conditioner is recommended for this sensor?

A2: The Epro CON021 or CON041 signal conditioner is commonly used to process signals from the PR6423 series sensors.

Q3: What is the output signal type of this sensor system?

A3: The system provides a voltage output proportional to the measured displacement, typically in mV/µm.

Q4: Is the sensor affected by the material of the target surface?

A4: Yes, calibration is optimized for conductive materials such as steel; different materials may affect sensitivity and linearity.

Q5: What is the recommended mounting method?

A5: The sensor can be mounted using threaded sleeves or brackets to maintain stable and precise alignment with the target shaft.

Q6: How does temperature influence sensor performance?

A6: The sensor is designed for minimal drift across a wide temperature range, maintaining accuracy within specified limits.

Q7: Can the sensor operate in oily or humid environments?

A7: Yes, with an IP67 protection rating, it can function reliably in environments with oil mist, humidity, and light contamination.

Q8: What cable options are available for this model?

A8: Standard models include 5 m coaxial cables, but customized lengths up to 10 m can be ordered.

Q9: Does the sensor require calibration after installation?

A9: Yes, a calibration procedure should be performed using the associated signal conditioner to ensure correct linear response.

Q10: Can this sensor be used with vibration monitoring systems other than Epro?

A10: Yes, it can be integrated with other compatible condition monitoring systems that support eddy-current probe inputs.

Related or Same-Series Models

| Model | Description | Sensor Head Diameter | Cable Length | Typical Use |

|---|---|---|---|---|

| PR6423/012-000 | Eddy-current sensor, 8 mm head, extended cable | 8 mm | 10 m | Turbine and compressor monitoring |

| PR6423/013-000 | Standard sensor with enhanced temperature range | 8 mm | 5 m | General industrial vibration measurement |

| PR6423/015-000 | Compact version for limited-space applications | 5 mm | 3 m | Pumps and small motors |

| PR6424/010-000 | 10 mm sensor version, longer range | 10 mm | 5 m | Heavy-duty shaft monitoring |

| PR6425/000-030 | High-temperature probe for harsh environments | 5 mm | 5 m | Gas turbine applications |

| PR6426/010-000 | Extended-range eddy-current sensor | 8 mm | 5 m | Precision machinery and compressors |

Popular Models from the Same Brand

| Model | Product Type | Measurement Range | Sensor Head Diameter | Weight |

|---|---|---|---|---|

| PR6424/000-010 | Eddy-Current Sensor | Up to 3 mm | 10 mm | 0.12 kg |

| PR6425/010-040 | High-Temp Eddy-Current Probe | Up to 2 mm | 5 mm | 0.08 kg |

| CON021 | Signal Conditioner Module | N/A | N/A | 0.25 kg |

| MMS6312 | Machine Monitoring System | Multi-channel | N/A | 1.5 kg |

| PR9376/010-000 | Extension Cable | N/A | N/A | 0.05 kg |

| PR6426/000-040 | Extended-Range Probe | Up to 4 mm | 8 mm | 0.1 kg |

Excellent PLC

Excellent PLC