| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

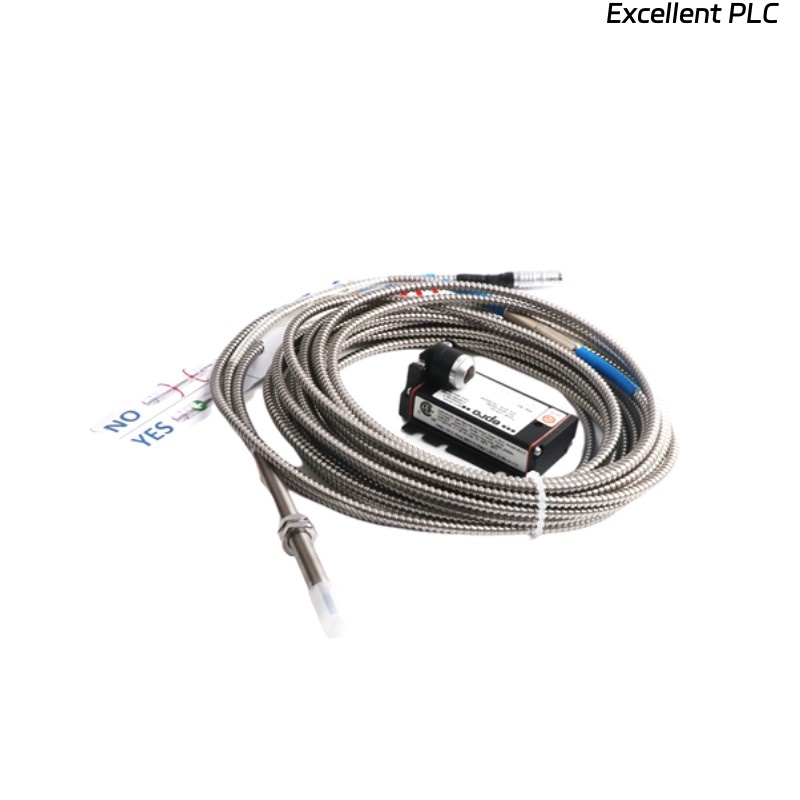

The Epro PR6423/010-010-CN 8mm Eddy Current Sensor is a high-precision, non-contact sensor designed for measuring displacement and vibration in industrial machinery. Utilizing eddy current technology, the sensor accurately detects the position and movement of metallic targets, providing real-time feedback critical for machinery monitoring and condition-based maintenance.

This sensor is widely used in turbines, compressors, pumps, and other rotating equipment. Its robust construction ensures reliable operation under harsh industrial conditions, including vibration, temperature fluctuations, and electromagnetic interference. By delivering high-resolution signals, it enables early detection of mechanical issues, improving reliability and reducing unplanned downtime.

Technical Specifications

| Parameter | Details |

|---|---|

| Model Number | PR6423/010-010-CN |

| Type | Eddy Current Displacement Sensor |

| Sensor Head Diameter | 8 mm |

| Measurement Range | 0–0.1 mm |

| Output Type | Differential voltage signal (mV) |

| Linearity | ±1% of full scale |

| Frequency Response | 0–10 kHz |

| Temperature Range | –20 °C to 120 °C |

| Operating Voltage | 18–30 V DC |

| Signal Conditioning | Integrated signal conditioning unit |

| Weight | 0.1 kg |

| Connector Type | M12 or compatible industrial connector |

| Housing Material | Stainless steel or high-strength alloy |

| Mounting | Threaded or flange mounting options available |

Applications

The PR6423/010-010-CN sensor is commonly applied in:

-

Rotating Machinery Monitoring: Measures shaft vibration and radial displacement in turbines, compressors, and pumps.

-

Predictive Maintenance: Detects early signs of misalignment, imbalance, or bearing wear.

-

Process Control: Provides precise feedback for automated control systems in industrial processes.

-

Industrial Equipment Testing: Used in test benches and laboratory setups for machinery performance evaluation.

-

High-Speed Rotating Equipment: Suitable for monitoring fast-rotating machinery components, ensuring safe and efficient operation.

Advantages

-

High Precision: Eddy current technology ensures accurate and reliable displacement measurements.

-

Non-Contact Measurement: Reduces wear and extends sensor life by eliminating physical contact.

-

Wide Frequency Response: Captures both low- and high-frequency vibrations in machinery.

-

Industrial-Grade Durability: Resistant to temperature fluctuations, vibrations, and electromagnetic interference.

-

Integrated Signal Conditioning: Delivers stable and reliable signals compatible with industrial monitoring systems.

-

Flexible Mounting: Can be installed using threaded or flange mounting options.

-

Compact and Lightweight: 8 mm sensor head diameter and 0.1 kg weight facilitate installation in confined spaces.

FAQ

1. What is the primary function of the PR6423/010-010-CN sensor?

It measures displacement and vibration of metallic targets using eddy current technology, providing accurate data for industrial monitoring and machinery diagnostics.

2. What is the sensor head diameter?

The sensor head diameter is 8 mm, allowing installation in tight spaces near rotating machinery components.

3. What measurement range does the sensor support?

It measures displacements from 0 to 0.1 mm, suitable for detecting very small movements in precision machinery.

4. What type of output signal does the sensor provide?

It provides a differential voltage signal in millivolts, compatible with industrial data acquisition and monitoring systems.

5. How linear is the sensor?

The sensor has ±1% full-scale linearity, ensuring precise proportional measurement of displacement.

6. What is the frequency response range?

The sensor responds to frequencies from 0 to 10 kHz, capturing both low- and high-frequency vibration signals.

7. What temperature range can the sensor operate within?

It operates reliably from –20 °C to 120 °C in harsh industrial environments.

8. What voltage is required for operation?

The sensor operates on a DC voltage range of 18–30 V.

9. Is it suitable for high-speed rotating equipment?

Yes, it can monitor radial displacement and shaft vibration in high-speed turbines, pumps, and compressors.

10. What mounting options are available?

It can be mounted using threaded or flange interfaces for flexible and secure installation.

Related Epro Models (Same Series or Function)

| Model | Description |

|---|---|

| PR6423/005-010 | 5 mm Eddy Current Displacement Sensor |

| PR6423/010-100 | 8 mm Standard Eddy Current Sensor |

| PR6423/015-050 | 15 mm Measurement Range Eddy Current Sensor |

| PR6424/010-040 | 8 mm High-Frequency Eddy Current Sensor |

| PR6425/008-100 | Compact 8 mm Industrial Eddy Current Sensor |

| CON021+PR6423/010 | Dual-Channel 8 mm Eddy Current Sensor |

Popular Epro Models

| Model | Description |

|---|---|

| MMS3120/022-100 | Standard Magnetic Pick-Up Sensor |

| MMS3125/022-020 | High-Precision Displacement Sensor |

| MMS3140/010-050 | 10 mm Vibration and Displacement Sensor |

| CON020+PR6423/005 | 5 mm Compact Eddy Current Sensor |

| MMS3130/015-100 | Medium-Range Eddy Current Sensor |

| CON021+PR6424/010 | High-Frequency 8 mm Eddy Current Sensor |

Excellent PLC

Excellent PLC