| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

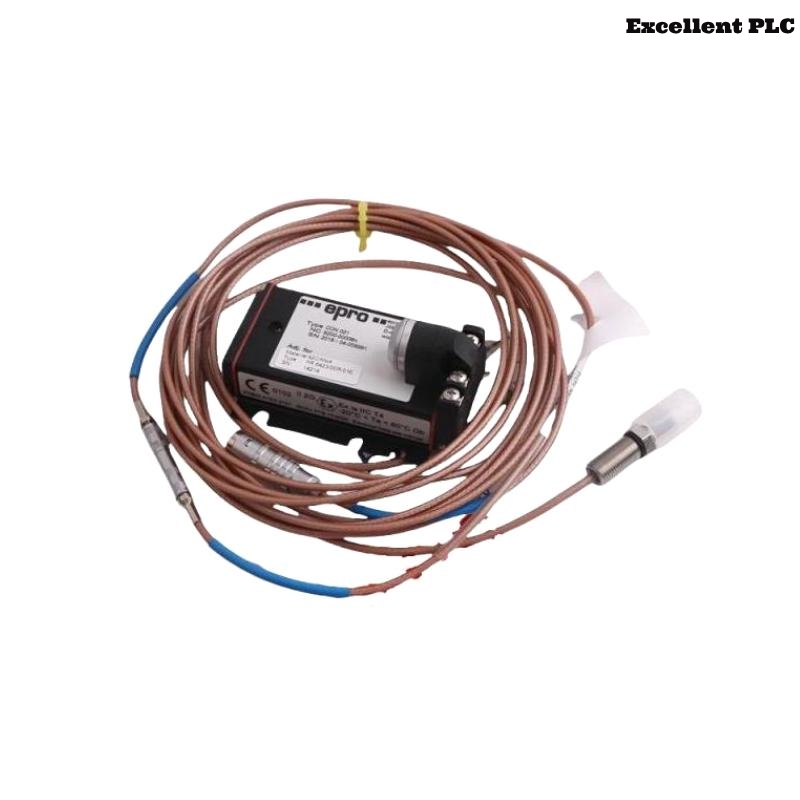

The Epro PR6423/010-110-CN is a high-performance eddy current displacement sensor, specifically engineered for continuous monitoring of shaft position and vibration in rotating machinery. As part of the proven Epro PR6423 series, this model integrates seamlessly with the CON0xx converter modules, enabling precise, non-contact measurements even in harsh industrial conditions.

With a robust 8mm probe tip, this sensor offers a well-balanced design suitable for installations requiring a wide linear range, high accuracy, and long-term stability. Its rugged construction makes it ideal for use in oil & gas, power generation, petrochemical, and heavy manufacturing industries where precise shaft monitoring is essential for preventing mechanical failure and optimizing maintenance intervals.

The “CN” suffix indicates a China-specific configuration, which may include custom cabling, voltage calibration, or compliance with regional specifications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model | PR6423/010-110-CN |

| Sensor Type | Eddy Current Proximity Sensor |

| Sensing Principle | Non-contact eddy current |

| Tip Diameter | 8 mm |

| Mounting Thread Type | M14 x 1 |

| Measurement Range | 0 to 2 mm (depending on target material and configuration) |

| Linearity Error | ≤ ±1% of full-scale output |

| Compatible Converter | CON011 / CON021 / CON031 |

| System Compatibility | VM600, MMS6000, BN 3500, BN 3300 |

| Cable Type | Integrated coaxial cable (shielded) |

| Cable Length | 5 meters (standard) — customizable |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Sensor Housing Material | Stainless Steel |

| Environmental Protection | IP65 (Sensor head) |

| Vibration Resistance | Up to 20 g (10–2000 Hz) |

| Shock Resistance | Up to 100 g (11 ms) |

| Electrical Output | Voltage (via converter) |

| Weight | 0.1 kg |

| Certifications | CE, ISO 9001, RoHS (ATEX optional) |

Product Applications

The PR6423/010-110-CN sensor is suited for a wide range of critical machinery monitoring tasks in industrial environments. It plays a pivotal role in preventive and predictive maintenance strategies:

-

Steam and Gas Turbines – For vibration and shaft displacement monitoring.

-

Compressors and Blowers – Early detection of imbalance and misalignment.

-

Pumps and Motors – Monitoring bearing wear and rotor shaft movement.

-

Gearboxes and Drives – Ensuring real-time condition data for rotating components.

-

Industrial Fans and Centrifuges – Preventing unplanned downtime due to shaft instability.

-

Petrochemical Plants – Integrated into hazardous area machinery for continuous condition tracking.

Product Advantages

-

Precision Monitoring: Provides accurate, real-time displacement readings with low drift.

-

Non-Contact Sensing: Eliminates mechanical wear, extending sensor lifespan.

-

High Reliability: Withstands harsh environments, temperature extremes, and mechanical shock.

-

Versatile Integration: Compatible with multiple monitoring systems (Epro, Bently Nevada, etc.).

-

Custom Configuration Options: Tailored versions available for cable length, connector type, or voltage.

-

Robust Mechanical Design: Stainless steel enclosure ensures resistance to corrosion and vibration.

-

Global & Local Compliance: Designed with international and China-specific standards in mind.

-

Cost-Effective Maintenance: Enables predictive maintenance, reducing unexpected downtime and repair costs.

Frequently Asked Questions (FAQ)

-

What is the purpose of the PR6423/010-110-CN sensor?

It is used for non-contact monitoring of shaft displacement and vibration in rotating machinery. -

Is this model compatible with the CON031 converter?

Yes, it is fully compatible with CON011, CON021, and CON031 converter modules. -

What is the difference between PR6423/010-110-CN and PR6423/10R-131?

The CN model is a China-specific variant with potential adjustments in calibration, cabling, or compliance. -

What is the sensor’s tip diameter?

It features an 8 mm diameter sensing tip, ideal for general-purpose proximity measurements. -

What systems can this sensor connect to?

It works with VM600, MMS6000, and legacy systems like BN3300 and BN3500. -

Can this sensor be used in high-temperature environments?

Yes, it operates reliably up to +180°C, with storage capability up to +200°C. -

Is the sensor suitable for hazardous locations?

ATEX-certified variants are available upon request for explosive environments. -

Does this sensor require periodic recalibration?

Minimal recalibration is needed due to its stable output; however, routine system checks are recommended. -

How is the sensor mounted?

It is mounted using an M14 x 1 threaded connection and secured with a lock nut. -

Can the cable be extended beyond 5 meters?

Yes, custom cable lengths are available, but proper matching with converter impedance is necessary.

Related or Same Series Models

| Model | Description | Tip Size | Compatible Converter |

|---|---|---|---|

| PR6423/005-010 + CON021 | Short probe for small clearance areas | 5 mm | CON021 |

| PR6423/10R-010 + CON031 | 8 mm probe with standard range | 8 mm | CON031 |

| PR6423/014-040 + CON041 | Probe with extended temperature rating | 8 mm | CON041 |

| PR6423/012-130 + CON031 | Probe with integrated shielded cable | 8 mm | CON031 |

| PR6423/002-030 + CON041 | 2 mm precision probe for narrow gaps | 2 mm | CON041 |

| PR6423/13R-140 + CON031 | Extra-long cable version for remote access | 8 mm | CON031 |

Popular Epro Models

| Model | Description | Application |

|---|---|---|

| MMS3120/022-100 | Vibration monitoring module | General machine protection |

| CON021 | 5mm eddy current signal converter | Works with PR6423/005 probes |

| MMS6312/022-000 | Dual-channel module for vibration/position | High-speed turbine monitoring |

| MMS6110/022-200 | Display unit with integrated diagnostics | Condition monitoring in real-time |

| PR6424/01CS + CON021 | Axial displacement probe with compact housing | Thrust position measurements |

| MMS6220/022-200 | Dual-channel temperature module | Bearing & lubrication monitoring |

Excellent PLC

Excellent PLC