| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

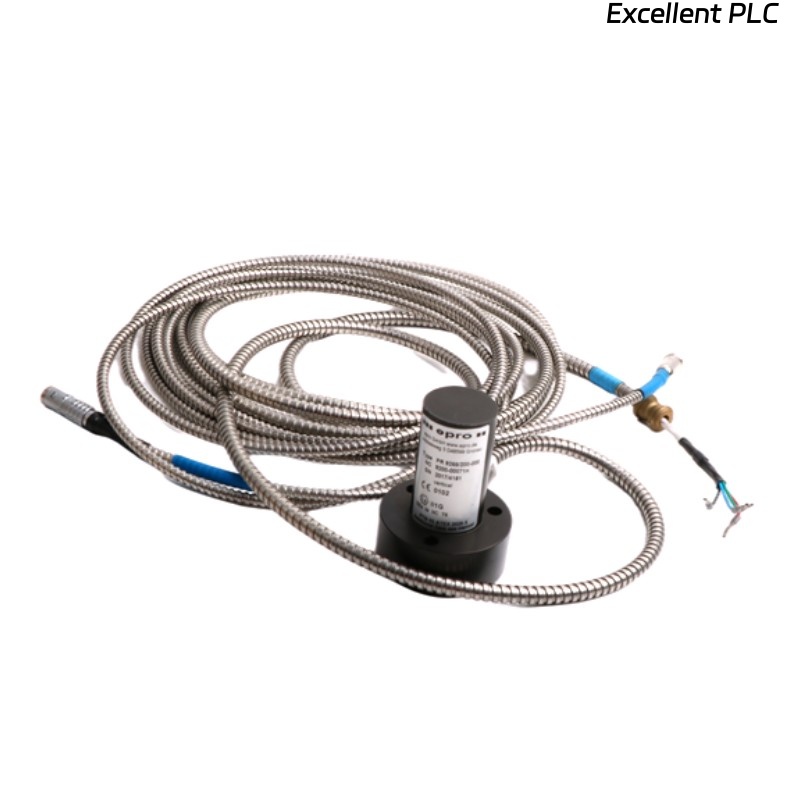

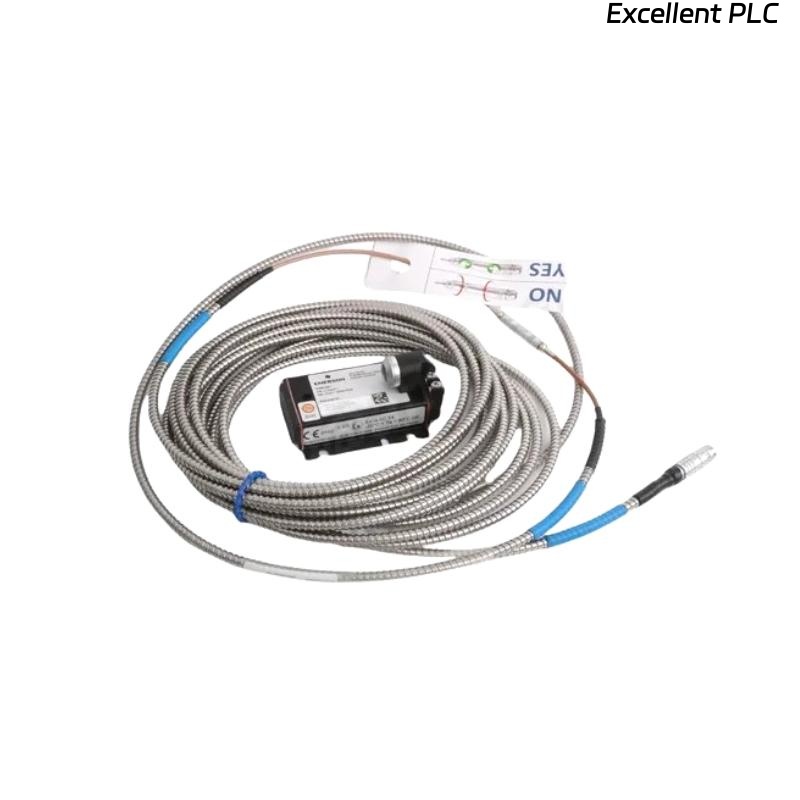

The Epro PR6423/015-010+CON021 8mm Eddy-Current Sensor is a high-precision proximity sensor designed for vibration and position measurement in critical industrial applications. Developed by Epro, a brand under Brüel & Kjær Vibro, this sensor is part of the renowned PR6423 series, known for its superior reliability and accuracy in harsh environments.

Product Advantages

-

High Measurement Accuracy: Provides highly linear and stable output for precise displacement and vibration readings.

-

Excellent Temperature Stability: Maintains performance consistency in temperature ranges up to 180°C.

-

Robust Construction: Stainless steel body with sealed probe tip ensures protection from oil and contaminants.

-

Wide Compatibility: Fully compatible with Epro’s CON021 and CON041 converters, and monitoring systems like VM600.

-

Low Drift and Noise: Advanced signal conditioning ensures minimal drift and electrical noise interference.

-

Maintenance-Free Design: No moving parts, ensuring long operational life and reduced maintenance cost.

Technical Specifications

| Parameter | Description |

|---|---|

| Model | Epro PR6423/015-010+CON021 |

| Measurement Principle | Eddy-current (non-contact) |

| Sensor Head Diameter | 8 mm |

| Nominal Measuring Range | 2 mm (typical) |

| Linear Range | ±1 mm |

| Output Signal | -2 V to -18 V (proportional to gap) |

| Frequency Response | DC to 10 kHz |

| Operating Temperature Range | -35°C to +180°C |

| Storage Temperature Range | -50°C to +200°C |

| Material | Stainless Steel |

| Cable Length | 10 meters (standard) |

| Converter Type | CON021 |

| Weight | 0.22 kg |

| Protection Rating | IP67 |

| Mounting Thread | M8 x 1 |

| Power Supply (via Converter) | ±15 VDC |

| Linearity Error | ≤ ±1% of full scale |

Product Applications

-

Turbomachinery monitoring: For detecting shaft vibration and axial displacement in turbines and compressors.

-

Gearbox and pump systems: Ensures reliability by tracking misalignment or imbalance.

-

Generator condition monitoring: Helps prevent mechanical failures by observing rotor position.

-

Predictive maintenance systems: Used in machinery protection systems to reduce unplanned downtime.

-

High-speed rotating equipment: Ideal for dynamic vibration analysis in demanding industrial setups.

-

Aerospace and power generation sectors: Suitable for harsh and temperature-extreme environments.

Product Advantages in Application

-

Enhanced Machine Safety: Early detection of mechanical faults before damage occurs.

-

Accurate Vibration Analysis: Provides consistent and repeatable readings for long-term monitoring.

-

Versatile Integration: Works seamlessly with Epro, VibroMeter, and B&K Vibro monitoring platforms.

-

Reduced Downtime: Predictive maintenance minimizes shutdown frequency.

-

Environmental Resistance: Unaffected by oil, water, or magnetic fields in the machinery environment.

FAQ

Q1: How does the Epro PR6423/015-010+CON021 measure displacement?

A1: It operates on the eddy-current principle, where changes in the magnetic field caused by a conductive target are converted into voltage signals proportional to the distance between the probe and the target.

Q2: What type of target materials can this sensor measure?

A2: It is optimized for ferromagnetic materials such as steel but can also measure non-ferromagnetic conductive metals with calibration adjustments.

Q3: Can the sensor be used with converters other than CON021?

A3: Yes, it can be paired with CON041 or compatible third-party eddy-current converters, but recalibration is recommended for accuracy.

Q4: How is linearity ensured across the measuring range?

A4: The sensor and converter pair are factory calibrated together to maintain linearity within ±1% of full-scale output.

Q5: What is the effect of temperature variation on measurement accuracy?

A5: Due to its temperature-compensated design, the PR6423/015-010 maintains stable readings up to 180°C, minimizing thermal drift.

Q6: How is electrical interference minimized?

A6: Shielded cables and differential signal transmission reduce noise and electromagnetic interference.

Q7: Can this sensor be used in hazardous areas?

A7: Yes, certain PR6423 variants are available with ATEX and IECEx certifications for use in hazardous environments.

Q8: How should the probe be mounted for optimal performance?

A8: The probe should be mounted perpendicular to the rotating shaft, with the correct gap (typically 1 mm nominal) and secured using the M8 thread.

Q9: What is the signal output range and how is it interpreted?

A9: The sensor produces a voltage output ranging from -2 V to -18 V corresponding to the measured distance, which can be processed by monitoring systems.

Q10: How does cable length affect the sensor’s accuracy?

A10: Cable length is part of the calibration; extending or shortening cables beyond the calibrated length (10 m) can affect linearity and signal stability.

Related Models

| Model | Description | Measuring Range | Cable Length | Connector Type |

|---|---|---|---|---|

| PR6423/000-030 | Standard 8mm eddy-current probe | 2 mm | 3 m | CON021 |

| PR6423/010-000 | Compact version, 8mm tip | 2 mm | 5 m | CON021 |

| PR6423/015-000 | Extended cable length version | 2 mm | 10 m | CON021 |

| PR6423/001-010 | Shielded probe for noise-critical areas | 2 mm | 5 m | CON021 |

| PR6423/000-040 | High-temperature variant | 2 mm | 4 m | CON041 |

| PR6423/016-010 | Enhanced sensitivity type | 3 mm | 10 m | CON021 |

Popular Models from the Same Brand

| Model | Product Type | Measurement Principle | Application Field | Special Feature |

|---|---|---|---|---|

| PR6424/010-010 | Eddy-Current Sensor | Non-contact displacement | Turbomachinery | Extended range |

| PR9268/010-000 | Vibration Velocity Sensor | Piezoelectric | Machinery vibration | Compact design |

| CON021 | Converter | Signal conditioning | PR6423 series | High linearity |

| CON041 | Converter | Signal conditioning | High-temp probes | Wide temperature range |

| MMS6000 | Monitoring System | Multi-channel | Machine protection | Modular structure |

| VM600 | Condition Monitoring Rack | Multi-sensor integration | Plant monitoring | Bently-compatible |

| PR6426/010-030 | Proximity Probe | Eddy-current | Shaft displacement | Wide dynamic range |

| PR9350 | Signal Cable | Shielded coaxial | Sensor connection | Low noise |

Excellent PLC

Excellent PLC