| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

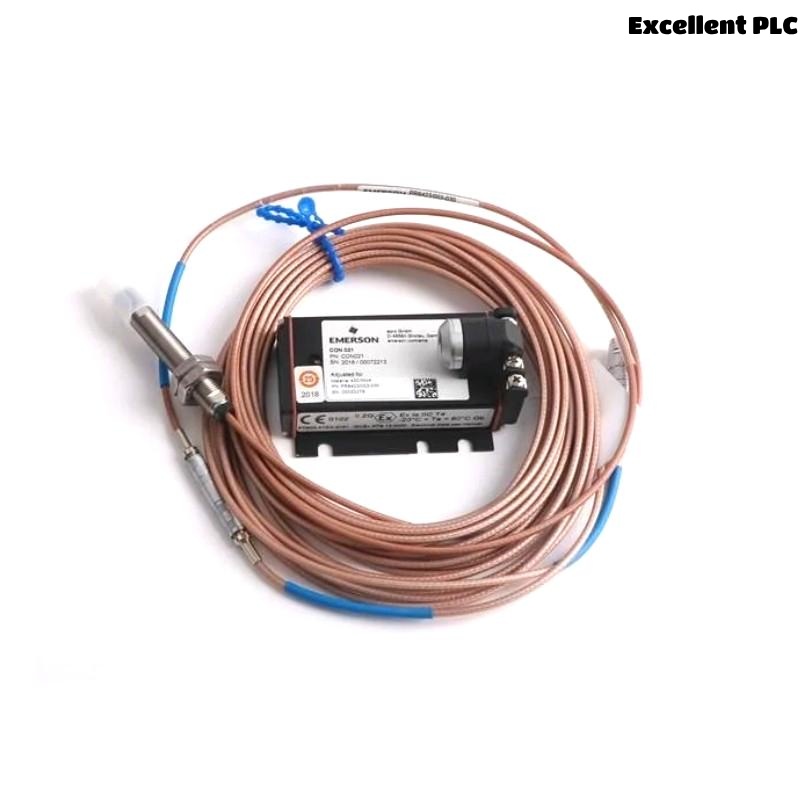

The Epro PR6423/10R-040 is a high-performance eddy current proximity sensor designed for non-contact measurement of shaft displacement, vibration, and speed in rotating machinery. Featuring a standard 8mm diameter sensing face, this model is part of Epro’s PR6423 series, known for its reliability and compatibility with advanced monitoring systems such as the CON011 converter and the MMS6000 condition monitoring platform.

Built to endure harsh industrial conditions, the sensor is engineered with a robust stainless steel housing, and is typically installed in applications such as turbines, compressors, pumps, and gearboxes. The PR6423/10R-040 is ideal for critical machine protection systems where real-time monitoring and fault diagnostics are essential for operational safety and performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6423/10R-040 |

| Sensor Type | Eddy Current Proximity Sensor |

| Sensing Range | 0.25 to 2.2 mm (Typical linear range) |

| Shaft Diameter Compatibility | ≥ 20 mm |

| Sensor Head Diameter | 8 mm |

| Material of Housing | Stainless Steel |

| Cable Length | 4.0 meters (040 = 4 meters fixed cable) |

| Connector Type | Compatible with CON011 |

| Operating Temperature | -35°C to +180°C (Sensor tip) |

| Storage Temperature | -40°C to +200°C |

| Frequency Response | Up to 10 kHz |

| Sensitivity | 7.87 mV/μm (±5%) depending on calibration |

| Linearity Error | ≤ ±1% of full-scale range |

| Protection Rating | IP65 |

| Dimensions (Sensor Head) | Ø8 mm x 55 mm (Length varies by model) |

| Weight | 0.1 kg |

| Mounting Thread | M10 x 1 |

| Certifications | CE, RoHS, ATEX (select configurations) |

Product Applications

The Epro PR6423/10R-040 is widely used across various industries requiring precision monitoring of rotating equipment. Applications include:

-

Steam and Gas Turbines – Shaft vibration monitoring for early detection of imbalance or misalignment.

-

Compressors – Real-time radial and axial displacement measurement.

-

Industrial Pumps – Monitoring bearing conditions and mechanical looseness.

-

Gearboxes and Motors – Shaft position monitoring to ensure optimal operation.

-

Hydropower Generators – Vibration analysis to prevent catastrophic mechanical failure.

-

OEM Machinery – Integrated as part of new-build rotating machine health monitoring systems.

Its robustness and accuracy make it suitable for use in oil & gas, power generation, chemical processing, marine propulsion, and aerospace ground testing sectors.

Product Advantages

-

Non-Contact Measurement: Eliminates physical wear and ensures long-term accuracy.

-

Wide Temperature Range: Suitable for high-temperature industrial environments.

-

Stainless Steel Construction: Provides excellent corrosion and mechanical resistance.

-

High Frequency Response: Captures fast and subtle shaft movement with precision.

-

Easy Integration: Fully compatible with CON011 converter and MMS monitoring systems.

-

Field-Proven Reliability: Extensively used in mission-critical applications worldwide.

-

Long Cable Variant (4m): Suited for installations where sensor mounting and connection points are distant.

-

Precise Calibration: High sensitivity ensures detection of minute displacements.

-

Industry Certifications: Compliant with international safety and performance standards.

-

Modular System Design: Part of Epro’s scalable condition monitoring ecosystem.

Frequently Asked Questions (FAQ)

-

What is the sensing principle of the PR6423/10R-040?

It uses eddy current technology for non-contact displacement and vibration measurement. -

What equipment is the sensor typically used with?

It is commonly paired with the CON011 converter and MMS6000 series monitoring systems. -

What does the “040” in the model number stand for?

It indicates a 4-meter integrated cable length. -

Is the sensor suitable for high-temperature environments?

Yes, it operates up to +180°C at the sensor tip. -

What materials is the sensor constructed from?

It has a stainless steel body, ensuring durability in industrial conditions. -

How accurate is the sensor?

It has a linearity error of less than ±1%, offering high measurement precision. -

What mounting thread is provided?

The sensor uses an M10 x 1 threaded housing for secure installation. -

Can this sensor be used in hazardous areas?

Yes, specific configurations are ATEX certified for explosive environments. -

How is the sensor connected to the monitoring system?

It connects to a CON011 converter using its built-in cable and compatible connectors. -

What is the minimum shaft diameter recommended for use?

Generally, shaft diameters above 20 mm are optimal for accurate sensing.

Recommended Related Models (Same Series or Functional Equivalents)

| Model Number | Description | Cable Length / Notes |

|---|---|---|

| PR6423/10R-030 | Eddy Current Sensor, 8mm Tip | 3.0 meters cable |

| PR6423/10R-020 | Eddy Current Sensor, 8mm Tip | 2.0 meters cable |

| PR6423/00R-010 | Sensor with 5mm tip for compact installations | Short-range version |

| PR6423/002-000 | Standard sensor, 8mm tip, general-purpose use | Compatible with CON011 |

| PR6423/005-010 | High-temperature version | Rated up to 220°C |

| PR6423/003-030 | Sensor with extended cable and sealed protection | Harsh environment applications |

Recommended Popular Epro Models (Same Brand)

| Model Number | Description | Application |

|---|---|---|

| CON011 | Signal converter for PR6423 series | Vibration monitoring interface |

| MMS3120/022-100 | Dual-channel vibration monitoring module | Turbomachinery systems |

| MMS6140 | High-speed data acquisition module | Online condition monitoring |

| PR6424/01CS | High-frequency eddy current sensor | Small gap measurements |

| PR6425/010-110 | Reverse mount sensor | Limited-access installations |

| MMS6000 | Modular monitoring system | Integrated machine protection |

Excellent PLC

Excellent PLC