| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

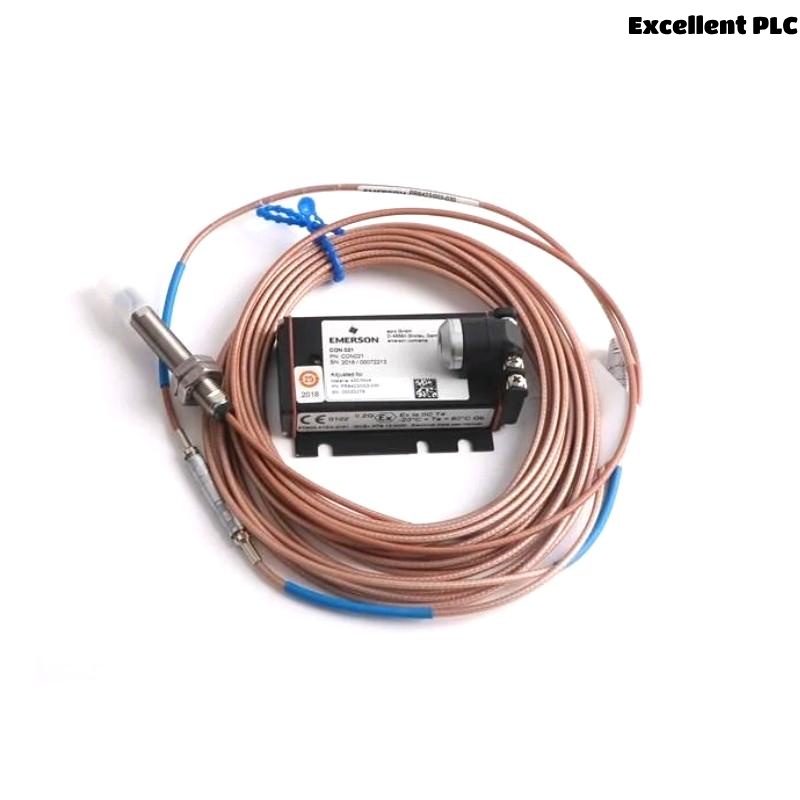

The Epro PR6424/000-000 + CON021 is a high-performance eddy current sensor designed specifically for non-contact measurement of shaft displacement, position, and vibration in rotating equipment. As a member of Epro’s highly regarded PR6424 series, this model features a 16mm probe diameter, making it ideal for medium-range measurements while maintaining precision and durability. This sensor is commonly used in conjunction with Epro’s CON021 converter, forming a robust system for condition monitoring in demanding industrial environments.

With its stainless-steel construction and resistance to temperature, pressure, and vibration, the PR6424/000-000 is frequently found in turbines, compressors, motors, and pumps in critical industrial sectors such as energy, petrochemicals, and heavy machinery manufacturing. This model is known for its long-term reliability, compatibility with various monitoring systems, and minimal maintenance requirements.

Product Specifications

| Parameter | Details |

|---|---|

| Model | PR6424/000-000 + CON021 |

| Sensor Type | Eddy Current Displacement Sensor |

| Sensor Head Diameter | 16 mm |

| Measurement Range | 0 to 2 mm (standard) |

| Sensitivity | ~7.87 mV/μm (typical with CON021) |

| Linearity | ±1% of Full Scale |

| Frequency Range | 0 to 10 kHz (-3dB) |

| Output Signal | Voltage Output via CON021 |

| Connector Type | CON021 (removable connection) |

| Cable Length | 5 m standard; customizable up to 10+ m |

| Operating Temperature | -35°C to +180°C |

| Storage Temperature | -40°C to +200°C |

| Vibration Resistance | Up to 20 g |

| Pressure Resistance | Up to 10 bar |

| Housing Material | Stainless Steel |

| Protection Class | IP68 (sensor), IP65 (connector) |

| Weight | 0.32 kg |

| Compliance | CE Marked; Optional ATEX Zone 1 Certification |

Product Applications

-

Steam and Gas Turbines

Used for monitoring radial shaft vibration and axial displacement, ensuring safe operation under dynamic loads. -

Compressors and Pumps

Tracks shaft movement and alignment in high-speed rotary machinery, preventing mechanical failure. -

Electric Motors and Generators

Assists in detecting misalignment, imbalance, and bearing wear in industrial motors. -

Oil and Gas Refineries

Suitable for hazardous zones with optional ATEX certification, offering precise machine diagnostics in critical systems. -

Power Plants and Hydropower Facilities

Ensures reliable machine health monitoring in turbines and rotating shafts under extreme environmental conditions. -

Machinery Condition Monitoring Systems (CMS)

Integrates seamlessly into Epro’s and other third-party condition monitoring systems for predictive maintenance.

Product Advantages

-

Medium-Sized Sensor Head (16 mm)

Balances size and range, ideal for standard industrial applications with limited mounting space. -

High Accuracy and Stability

Provides consistent measurement results with excellent linearity and low drift over time. -

Rugged Stainless-Steel Build

Designed for harsh environments, including high temperature, vibration, and corrosive conditions. -

Modular Configuration

Replaceable sensor, extension cable, and converter simplify maintenance and reduce downtime. -

Non-Contact Operation

Eliminates mechanical wear and ensures long sensor life, reducing total cost of ownership. -

Wide Environmental Compatibility

Withstands high pressure, moisture, and industrial contaminants due to IP68-rated protection. -

Certified for Hazardous Environments

Optional ATEX compliance enables use in explosive or flammable zones. -

Standardized Output with CON021

Ensures consistent integration into existing systems without the need for additional adapters. -

Global Industry Adoption

Trusted by top-tier OEMs and end users for mission-critical machinery health monitoring. -

Customizable Cable and Mounting Options

Flexible design options allow adaptation to various machine configurations and layouts.

Frequently Asked Questions (FAQ)

-

What does the PR6424/000-000 sensor measure?

It measures displacement, shaft vibration, and position in rotating equipment using eddy current technology. -

What is the typical application range of this model?

Ideal for 0–2 mm displacement measurements, depending on calibration and target material. -

Can this sensor be installed in hazardous areas?

Yes, with an optional ATEX-certified version, it can be used in explosive zones. -

Is the sensor compatible with non-Epro monitoring systems?

Yes, via standard signal output and converters, it can interface with third-party systems. -

What is the expected service life of the PR6424 sensor?

Typically over 10 years in normal conditions with minimal maintenance. -

How is the sensor mounted on machinery?

It is typically installed using threaded sleeves or brackets with precise alignment to the shaft surface. -

Does it require calibration after installation?

Calibration is required during the initial setup to ensure accurate measurements. -

Is the CON021 converter necessary for this model?

Yes, it works as part of a system with CON021 to process and output the voltage signal. -

What type of materials can the sensor detect?

The sensor is designed to work with conductive targets such as steel or other ferromagnetic materials. -

Can the sensor be submerged in liquid?

Yes, the sensor head is IP68-rated, meaning it can be fully submerged under specific conditions.

Related Models (Same Series or Functionality)

| Model | Probe Diameter | Measurement Range | Connector Type | Application Highlight |

|---|---|---|---|---|

| PR6424/010-120+CON021 | 16 mm | 0–2 mm | CON021 | For use in high-vibration environments |

| PR6424/014-140+CON041 | 16 mm | 0–2 mm | CON041 | High temperature tolerance |

| PR6424/006-030+CON011 | 16 mm | 0–2 mm | CON011 | For limited-space mounting |

| PR6424/012-100+CON031 | 16 mm | 0–2 mm | CON031 | Designed for gas turbine applications |

| PR6424/007-000+CON021 | 16 mm | 0–2 mm | CON021 | Optimized for vibration monitoring |

| PR6424/013-040+CON011 | 16 mm | 0–2 mm | CON011 | For hydropower rotating machines |

Popular Models from the Same Brand (Epro / Brüel & Kjær Vibro)

| Model | Function | Probe Size | Application | Output Type |

|---|---|---|---|---|

| PR6423/000-031+CON021 | Eddy current sensor | 8 mm | Compact spaces in compressors | Voltage output |

| PR6426/010-140+CON010 | Eddy current sensor | 32 mm | Large-range turbine shaft monitoring | Voltage output |

| PR9268/201-000 | Vibration velocity sensor | N/A | Fans, motors, pumps | IEPE signal |

| MMS3120/022-100 | Monitoring module | N/A | Turbine and compressor systems | Analog + Digital |

| MMS6120 | Vibration monitoring system | N/A | Multi-channel industrial diagnostics | Ethernet/Serial |

| CON021 | Signal converter | N/A | Used with PR6423/24/26 series | Passive/Voltage |

Excellent PLC

Excellent PLC