| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

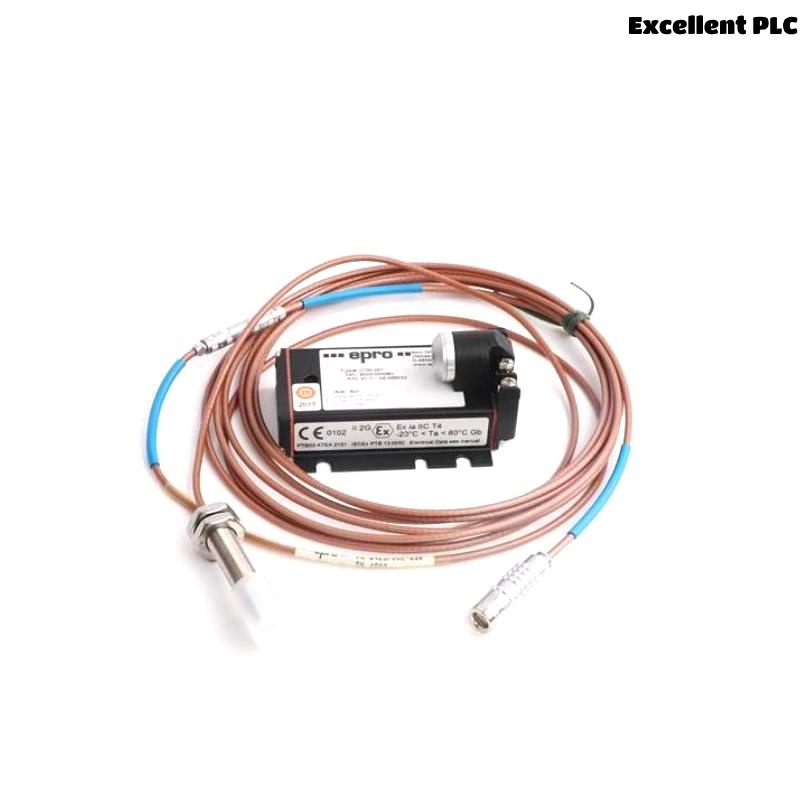

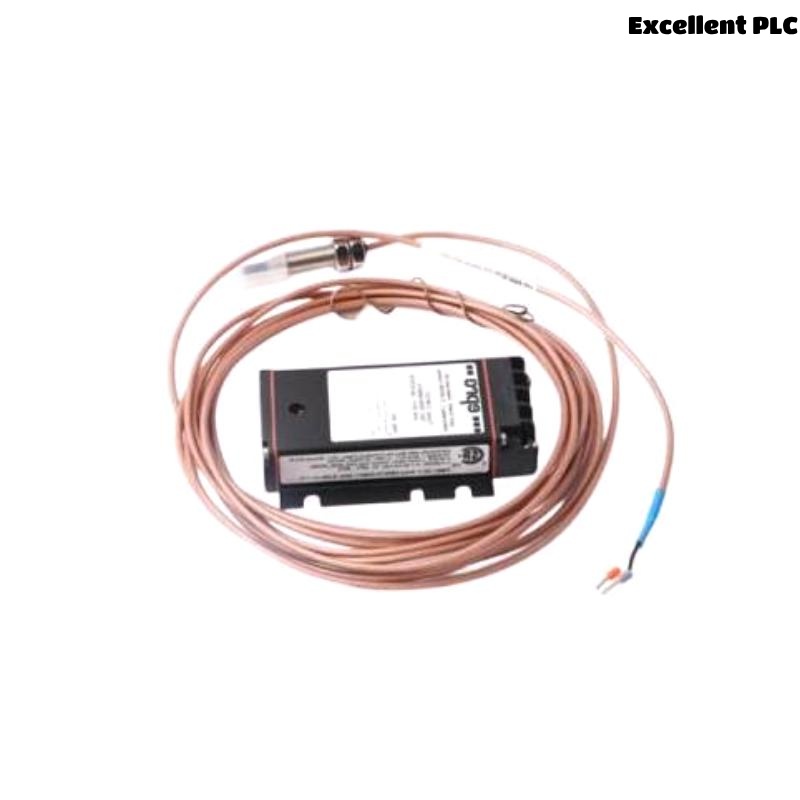

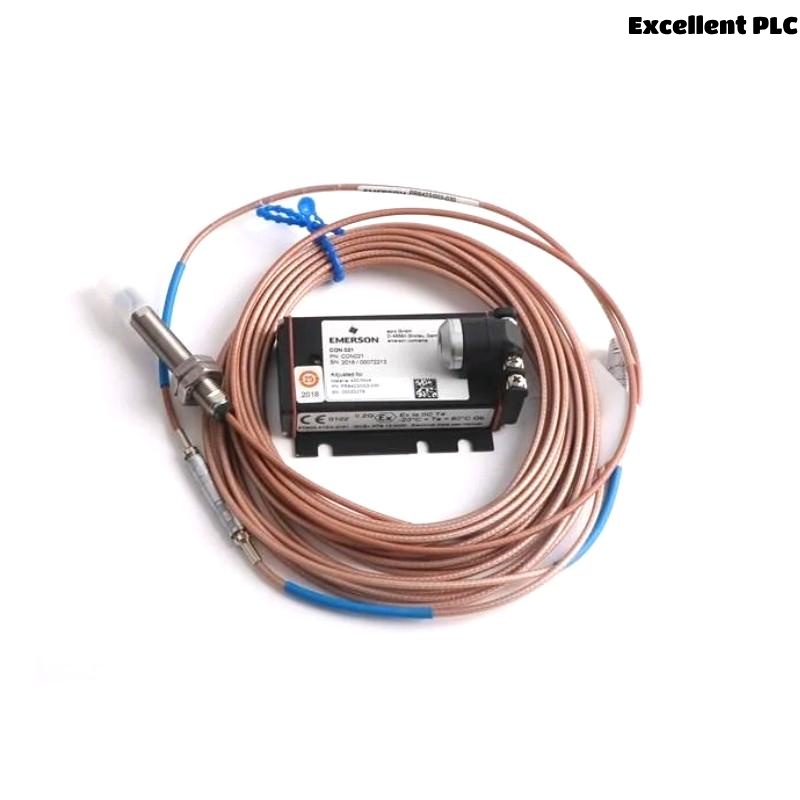

The Epro PR6424/000-030+CON021 16mm Eddy Current Sensor is a precision non-contact sensor designed to monitor displacement, position, and vibration in rotating machinery. This model uses the eddy current principle to measure the distance between the sensor and a conductive target, such as the shaft or bearing of a motor, turbine, or compressor. The sensor is ideal for applications in industries where high precision and reliability are critical, such as power generation, oil and gas, petrochemical, and manufacturing.

This particular model is equipped with a 16mm probe, offering a robust and accurate solution for larger shaft diameters and longer-range measurements. The CON021 module ensures seamless integration with monitoring systems, providing a stable signal output for real-time analysis of machinery condition. Whether for vibration monitoring, rotor displacement, or misalignment detection, the PR6424/000-030 sensor provides outstanding performance.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6424/000-030+CON021 |

| Sensor Type | Eddy Current Proximity Sensor |

| Sensing Range | Up to 3 mm (depending on target material) |

| Sensor Head Diameter | 16 mm |

| Thread Type | M14x1.5 |

| Probe Material | Stainless Steel |

| Cable Length | Customizable (typically 5m, 7m, 9m, or 10m) |

| Frequency Range | 0 to 10 kHz |

| Operating Temperature Range | -35°C to +180°C (sensor), -35°C to +90°C (CON021 module) |

| Output Signal | Voltage proportional to the gap distance |

| Sensitivity | Typically 7.87 mV/μm |

| Linearity Error | ≤ ±1% over full range |

| Power Supply | 24 VDC (via CON021 converter) |

| Electrical Isolation | Galvanic isolation from signal ground |

| Mounting | Threaded mount with locknut |

| Environmental Protection | IP65 or higher |

| Compliance | CE, RoHS |

| Weight | 0.32 kg |

Product Applications

-

Turbine Monitoring: Ideal for monitoring the displacement of turbine shafts, enabling early detection of misalignment or vibration problems.

-

Power Generation: Widely used in power plants for rotor monitoring, ensuring safe and efficient operation of generators and motors.

-

Petrochemical Industry: Helps monitor the health of rotating equipment in high-temperature and corrosive environments.

-

Condition Monitoring Systems: Integrates seamlessly with condition monitoring platforms to help predict machinery failures before they happen.

-

Pumps and Motors: Accurately measures vibration and displacement, preventing damage to pumps, compressors, and electric motors.

-

Manufacturing and Automation: Provides continuous monitoring of industrial machinery, reducing downtime and improving productivity.

Product Advantages

-

High Precision: Offers exceptional accuracy and reliability for monitoring machine displacement and vibration.

-

Non-Contact Measurement: Eliminates wear and tear on sensors, increasing their lifespan and reducing maintenance needs.

-

Robust Construction: Built from high-quality stainless steel to withstand harsh industrial environments, including high temperatures and corrosive conditions.

-

Flexible Integration: The sensor is compatible with a wide range of monitoring and control systems, making it suitable for various applications.

-

Wide Operating Temperature Range: Withstanding temperatures from -35°C to +180°C, the sensor is ideal for extreme environments.

-

Easy Mounting: The threaded mount allows easy installation in different orientations, simplifying integration into existing machinery.

-

Signal Stability: The CON021 module provides consistent, interference-free signal output for reliable monitoring.

-

Versatile Sensing Capabilities: The sensor can detect small changes in distance with high sensitivity, useful for precise vibration or position measurements.

-

Low Power Consumption: The sensor operates on a 24V DC supply, ensuring energy efficiency.

-

Long-Lasting Durability: The combination of high-quality materials and design ensures a long service life with minimal need for calibration.

Frequently Asked Questions (FAQ)

-

How does the PR6424/000-030 sensor work?

The sensor uses the eddy current principle to measure the distance between the sensor and a conductive target by detecting changes in the electromagnetic field as the distance varies. -

What is the typical operating range of the sensor?

The sensor can measure distances up to 3 mm, depending on the material and conditions of the target. -

Can the sensor operate in extreme temperatures?

Yes, the sensor is rated for temperatures from -35°C to +180°C, making it suitable for both cold and hot industrial environments. -

What is the role of the CON021 module?

The CON021 module serves as a signal converter and power interface, ensuring that the sensor’s output is compatible with monitoring systems. -

How long is the cable on the sensor?

The cable length can be customized, with standard lengths being 5m, 7m, 9m, or 10m, depending on customer needs. -

What industries benefit from this sensor?

The PR6424/000-030 sensor is ideal for industries such as power generation, petrochemical, manufacturing, and any industry with rotating machinery that requires vibration or displacement monitoring. -

What is the output signal of the sensor?

The sensor provides a voltage output that is proportional to the gap distance between the sensor and the target, allowing easy integration with monitoring systems. -

Is the sensor compatible with other monitoring systems?

Yes, the sensor is designed to integrate seamlessly with Epro systems and other third-party machinery monitoring systems. -

Does the sensor need frequent calibration?

No, the PR6424/000-030 is factory calibrated and does not require frequent calibration for long-term operation. -

Can the sensor be used in hazardous environments?

While the PR6424/000-030 sensor is designed for high-temperature and corrosive environments, specific hazardous-area certifications (e.g., explosion-proof) should be verified before use.

Related Models from Same Series

| Model | Description | Tip Diameter | Thread Type | Operating Temp |

|---|---|---|---|---|

| PR6424/000-130 | Long-range version for larger shaft diameters | 16 mm | M14x1.5 | -35°C to +180°C |

| PR6424/000-010 | Compact version for small machinery | 10 mm | M10x1 | -35°C to +180°C |

| PR6424/001-030 | High-sensitivity sensor for precision applications | 16 mm | M14x1.5 | -35°C to +180°C |

| PR6424/001-040 | Extended range sensor for high-speed machinery | 16 mm | M14x1.5 | -35°C to +180°C |

| PR6424/002-030 | Coated version for corrosive environments | 16 mm | M14x1.5 | -35°C to +180°C |

| PR6424/003-030 | Standard model for general-purpose applications | 16 mm | M14x1.5 | -35°C to +180°C |

Popular Epro Models

| Model | Function | Type | Application Area |

|---|---|---|---|

| MMS6312 | Dual-channel vibration monitoring module | Vibration Monitor Module | Machinery Protection |

| MMS3120/022-100 | Proximity measurement module | Signal Conditioning Module | Displacement Monitoring |

| MMS6410 | Four-channel vibration analysis system | Diagnostic Module | Condition Monitoring |

| PR6423/005-010 | Eddy current probe with compact design | Eddy Current Sensor | Turbine Vibration Monitoring |

| CON041 | Signal converter for PR6423/PR6424 sensors | Interface Converter | Industrial Sensors |

| CON021 | Signal converter for PR6424 series | Interface Converter | Measurement Systems |

Excellent PLC

Excellent PLC