| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

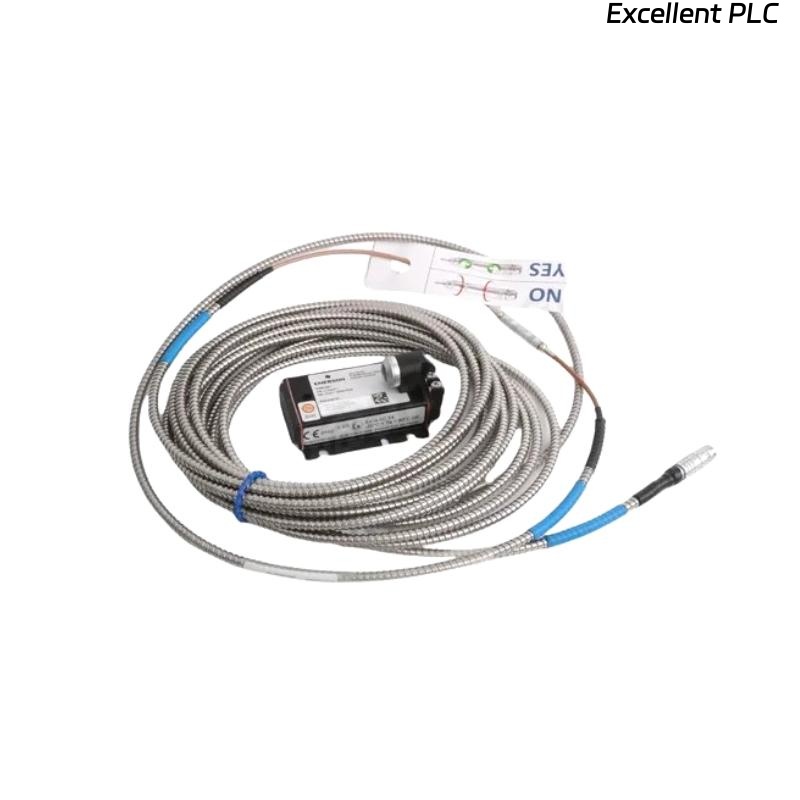

The Epro PR6424/010-120 16mm Eddy Current Sensor is a high-precision proximity probe designed to provide reliable and accurate displacement and vibration measurements in rotating machinery. Part of the well-established PR6424 series, this sensor is optimized for industrial condition monitoring, machine protection, and predictive maintenance applications.

With a 16 mm sensor head diameter, the PR6424/010-120 delivers consistent and repeatable readings in harsh operating environments, including high temperatures, vibration, and electromagnetic interference. When paired with Epro CON-series drivers (CON021, CON031, CON041), it provides stable linear outputs for integration with monitoring systems. It is widely used in turbines, compressors, pumps, and generators to enhance system reliability and prevent unscheduled downtime.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6424/010-120 |

| Product Type | Eddy Current Proximity Sensor |

| Sensor Head Diameter | 16 mm |

| Measurement Range | Up to 2.0 mm (depending on driver configuration) |

| Linear Range | ±10% of calibrated gap |

| Sensitivity | 7.87 mV/µm (nominal with compatible driver) |

| Frequency Response | DC to 10 kHz |

| Resolution | <0.5 µm |

| Operating Voltage | Supplied via CON-series driver module |

| Probe Material | Stainless steel housing with robust insulation |

| Operating Temperature | -35°C to +180°C (sensor head) |

| Storage Temperature | -40°C to +200°C |

| Humidity | 0–95% non-condensing |

| Certifications | CE, ATEX, IECEx (for hazardous locations) |

| Weight | 0.2 kg |

| Mounting | Threaded sleeve for secure installation |

| Compatibility | Epro CON021, CON031, CON041 driver modules |

Applications

The PR6424/010-120 sensor is widely used in industrial sectors where precise non-contact measurement is essential:

-

Turbines – Continuous monitoring of shaft displacement to detect misalignment and imbalance.

-

Compressors – Measurement of vibration and rotor position for operational safety.

-

Pumps – Monitoring mechanical performance to detect wear or cavitation.

-

Generators and Motors – Ensures stable operation and early fault detection.

-

Petrochemical Plants – Provides reliable measurements in hazardous zones.

-

Machine Protection Systems – Integrates into API 670-compliant protection platforms.

Advantages

The PR6424/010-120 16mm Eddy Current Sensor offers multiple operational and technical benefits:

-

High Accuracy – Ensures precise monitoring of shaft displacement and vibration.

-

Robust Construction – Stainless steel housing resists industrial wear and harsh environments.

-

Hazardous Area Certifications – Suitable for ATEX and IECEx certified applications.

-

Wide Frequency Range – Capable of measuring low- and high-speed machine vibrations.

-

Driver Compatibility – Works seamlessly with multiple CON-series drivers.

-

Maintenance-Free Operation – Non-contact design reduces mechanical wear.

-

Temperature Stability – Reliable readings across -35°C to +180°C.

-

Predictive Maintenance Support – Enables early fault detection and reduces unscheduled downtime.

Frequently Asked Questions (FAQ)

-

Which driver modules are compatible with the PR6424/010-120?

It is compatible with Epro CON021, CON031, and CON041 modules. -

What is the nominal sensitivity of the sensor?

7.87 mV/µm when paired with a matching driver. -

What is the frequency response of the sensor?

The sensor supports DC to 10 kHz. -

What is the operating temperature range of the probe head?

The probe head operates from -35°C to +180°C. -

Can this sensor be used in hazardous areas?

Yes, it is ATEX and IECEx certified for safe use in explosive atmospheres. -

What is the linear measurement range?

±10% of the calibrated gap. -

How is the sensor powered?

It receives power via the connected CON-series driver module. -

Is this sensor suitable for API 670-compliant systems?

Yes, it is compatible with API 670 machine protection standards. -

Does the sensor output a conditioned signal directly?

No, the probe signal is conditioned by the driver into a standard output. -

Does cable length affect measurement accuracy?

Yes, using the correct cable length is critical because calibration is based on specified lengths.

Related Models (Same Series)

| Model Number | Sensor Type | Description |

|---|---|---|

| PR6424/000-010 | Eddy Current Sensor | Standard monitoring probe |

| PR6424/002-031 | Eddy Current Sensor | High-precision 16 mm version |

| PR6424/006-030 | Eddy Current Sensor | Compact design for tight installations |

| PR6424/014-040 | Eddy Current Sensor | Extended temperature range version |

| PR6424/01CS | Eddy Current Sensor | Special calibration for unique applications |

| PR6424/017-100 | Eddy Current Sensor | High-sensitivity version for critical measurement |

Popular Models from the Same Brand (Epro)

| Model Number | Product Type | Description |

|---|---|---|

| PR6423/005-010 | Eddy Current Sensor | 8 mm probe for general vibration monitoring |

| PR6423/010-140 | Eddy Current Sensor | Long-range probe for large machinery |

| MMS3120/022-100 | Monitoring Module | Machine monitoring and protection module |

| MMS3125/022-020 | Monitoring Module | Vibration and condition monitoring system |

| CON021 | Driver Module | Standard driver for PR642x series sensors |

| CON041 | Driver Module | Advanced driver with enhanced signal processing |

Excellent PLC

Excellent PLC