| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

Product Introduction

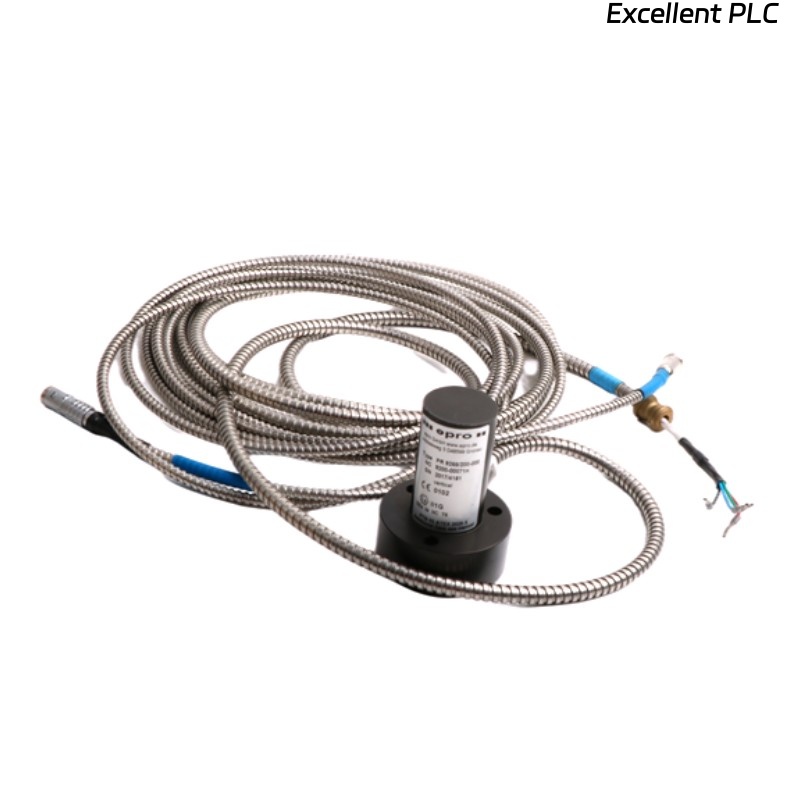

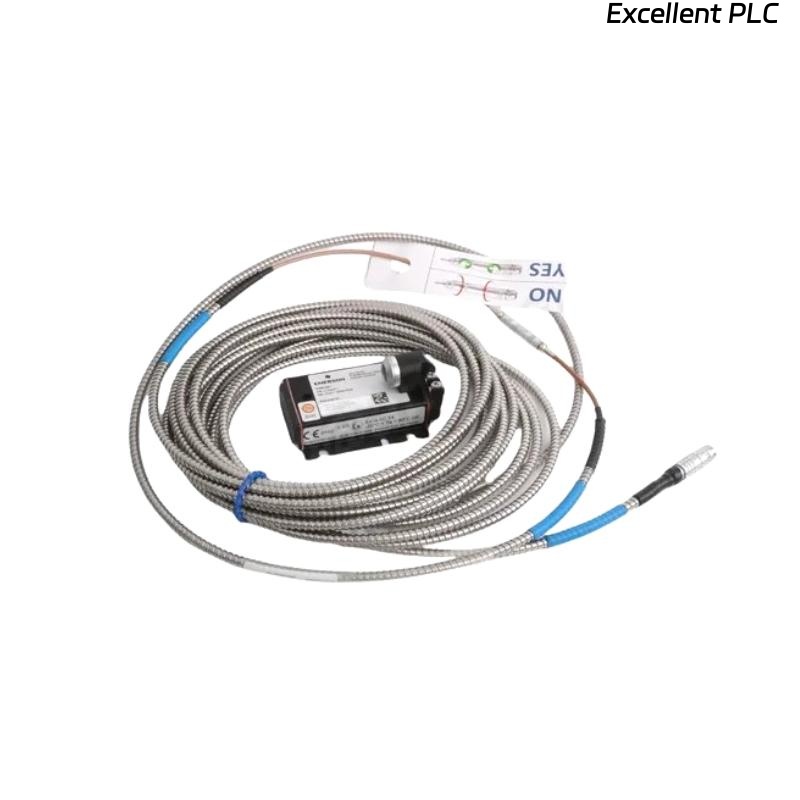

The Epro PR6424/010-120 + CON011 is a high-precision eddy current displacement sensor designed for non-contact vibration and axial position measurements in rotating machinery. This sensor is part of the renowned Epro PR6424 series, often used in conjunction with the CON011 converter module, enabling precise signal processing and output compatibility with vibration monitoring systems like VM600 or MMS6000.

Engineered for demanding industrial environments, the sensor is ideal for applications in turbines, compressors, pumps, and motors where high-reliability condition monitoring is critical. The 16 mm probe diameter ensures an optimal balance between measurement range and structural robustness, and its stainless-steel construction ensures high resistance to corrosive elements and temperature variations.

Product Specifications

| Parameter | Specification |

|---|---|

| Product Name | PR6424/010-120 + CON011 |

| Manufacturer | Epro (A brand of Emerson / Brüel & Kjær Vibro) |

| Sensor Type | Eddy current displacement sensor |

| Sensor Head Diameter | 16 mm |

| Measurement Range | 0 to 4 mm (typical) |

| Linearity | ≤ ±1% of full-scale output |

| Temperature Range (Sensor) | -35°C to +180°C |

| Temperature Range (CON011) | -25°C to +70°C |

| Frequency Response | DC to 10 kHz (-3 dB) |

| Output Signal | Voltage signal proportional to distance |

| Mounting Thread | M14x1.5 or customized thread |

| Material | Stainless steel (probe and housing) |

| Environmental Protection | IP65 (Sensor head) |

| Compatibility | VM600, MMS6000, and other standard monitoring systems |

| Connector Type | Matched to CON011 via coaxial connection |

| Vibration Limit (Sensor) | 100 m/s² (continuous) |

| Shock Limit | 500 m/s² |

| Insulation Resistance | ≥ 100 MΩ at 500 VDC |

| Weight | 0.32 kg |

Product Applications

-

Turbomachinery Monitoring: Ideal for use in gas turbines, steam turbines, and hydro turbines to monitor shaft vibration and axial displacement.

-

Compressor Systems: Ensures precise vibration detection in centrifugal and reciprocating compressors.

-

Pump Condition Monitoring: Detects early-stage wear or imbalance in critical pump installations.

-

Generator Sets: Monitors shaft movement and ensures mechanical integrity in power generation applications.

-

Industrial Motors: Supports diagnostics in high-speed motor applications to avoid critical failures.

-

Axial Thrust Monitoring: Used in bearing protection systems to measure axial shaft position and thrust movement.

-

Gearbox Vibration Monitoring: Detects misalignment or tooth damage in industrial gearbox systems.

Product Advantages

-

High-Resolution Measurement: Capable of detecting minute displacement changes down to microns, supporting proactive maintenance strategies.

-

Robust Mechanical Design: Made of corrosion-resistant stainless steel for long-term reliability in harsh environments.

-

Excellent Temperature Stability: Wide operating range ensures performance across extreme industrial conditions.

-

Non-Contact Sensing: Eliminates mechanical wear and delivers maintenance-free operation in continuous monitoring setups.

-

Wide Compatibility: Easily integrates with established monitoring systems like VM600 or MMS6000 without modification.

-

Optimized Signal Conditioning: When paired with the CON011 converter, signal output is clean, linear, and suitable for high-speed data acquisition.

-

Field Proven: Trusted in petrochemical, energy, marine, and heavy machinery sectors worldwide.

-

Configurable Lengths & Threads: Offers a wide variety of installation options tailored to OEM requirements.

FAQ

-

What is the recommended linear range of the PR6424/010-120 sensor?

The linear range is typically 0 to 4 mm, with optimal linearity within ±1% of full-scale output. -

How does the sensor output correlate to displacement?

The sensor provides a voltage signal directly proportional to the distance between the probe tip and the target surface. -

What type of materials can the sensor detect accurately?

The sensor is calibrated for conductive targets, typically ferromagnetic metals like steel, used in rotors and shafts. -

Can the sensor be used in high-vibration environments?

Yes, it supports continuous operation in environments with vibration levels up to 100 m/s². -

Is calibration required when replacing the sensor?

Calibration is recommended after replacement to ensure accuracy, particularly when sensor or cable length differs from the original configuration. -

What is the effect of temperature on sensor performance?

The sensor is temperature-compensated, but extreme temperature fluctuations may require recalibration for optimal accuracy. -

How is the sensor connected to the monitoring system?

The sensor connects to the CON011 converter via a coaxial cable, which conditions and outputs a standard signal to the monitoring device. -

Is electromagnetic interference (EMI) a concern?

No, the sensor and CON011 unit are designed with shielding and grounding features to minimize EMI effects. -

Can this sensor detect both radial and axial displacement?

Yes, it depends on the installation orientation—radial mounting measures shaft vibration, while axial mounting measures thrust movement. -

What is the recommended gap between the sensor tip and the target?

The recommended initial gap is typically between 1.0 mm to 2.0 mm, depending on the application and desired measurement range.

Related Models

| Model | Description | Probe Diameter | Measurement Range |

|---|---|---|---|

| PR6424/000-010 + CON011 | Standard version for small gaps | 5 mm | 0–1 mm |

| PR6424/006-030 + CON011 | Extended temperature version | 8 mm | 0–2 mm |

| PR6424/012-040 + CON011 | Larger probe for extended range | 25 mm | 0–8 mm |

| PR6424/002-030 + CON011 | Short sensor tip variant | 5 mm | 0–1.5 mm |

| PR6424/014-040 + CON021 | High-temp and high-frequency variant | 16 mm | 0–4 mm |

| PR6424/01CS + CON041 | Explosion-proof certified variant | 16 mm | 0–4 mm |

Popular Models from Epro

| Model | Description | Application Area |

|---|---|---|

| MMS3120/022-100 | Monitoring module for vibration and position signals | Turbomachinery diagnostics |

| MMS6110 | Universal monitor for eddy current sensors | General condition monitoring |

| CON021 | Signal converter for PR6423 and PR6424 sensors | Signal conditioning |

| PR6423/002-030 | Eddy current sensor with 8 mm probe diameter | Compact installations |

| TQ402 | Velocity sensor with dynamic signal output | Gearbox and motor analysis |

| PR9268/201-000 | Accelerometer for high-frequency vibration detection | Machine condition monitoring |

Excellent PLC

Excellent PLC