| Company Information | ||||||||

| [email protected] | ||||||||

| Mobile | +8613666033393 | |||||||

| +8613666033393 | ||||||||

| 13666033393 | ||||||||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China | |||||||

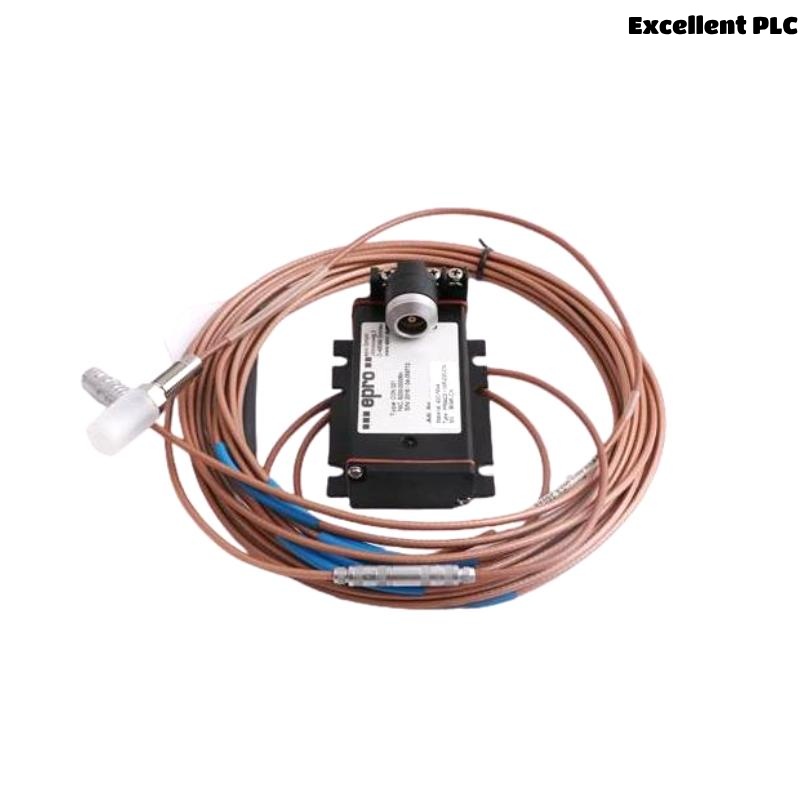

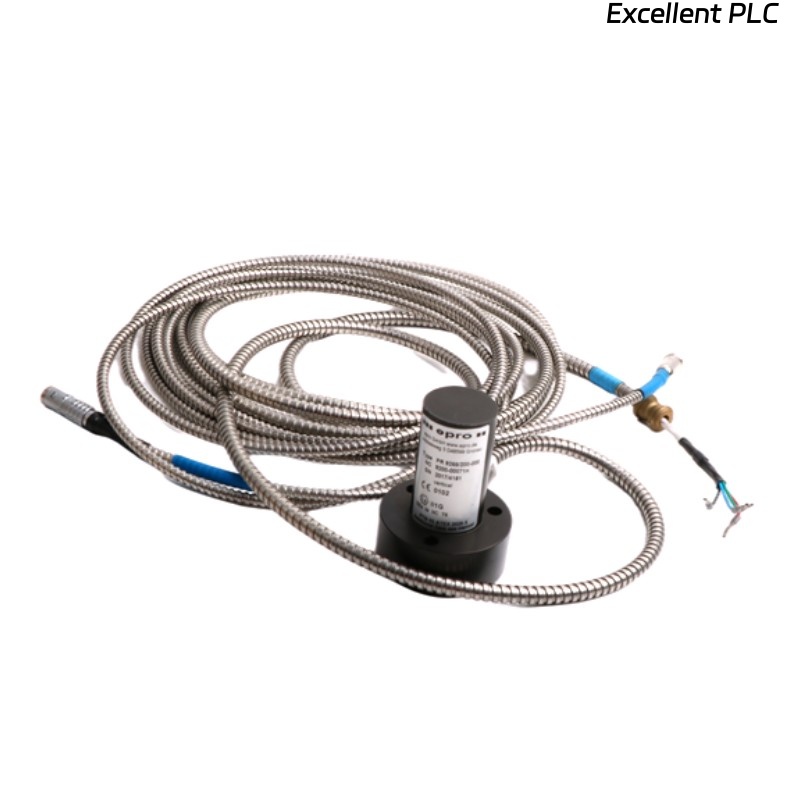

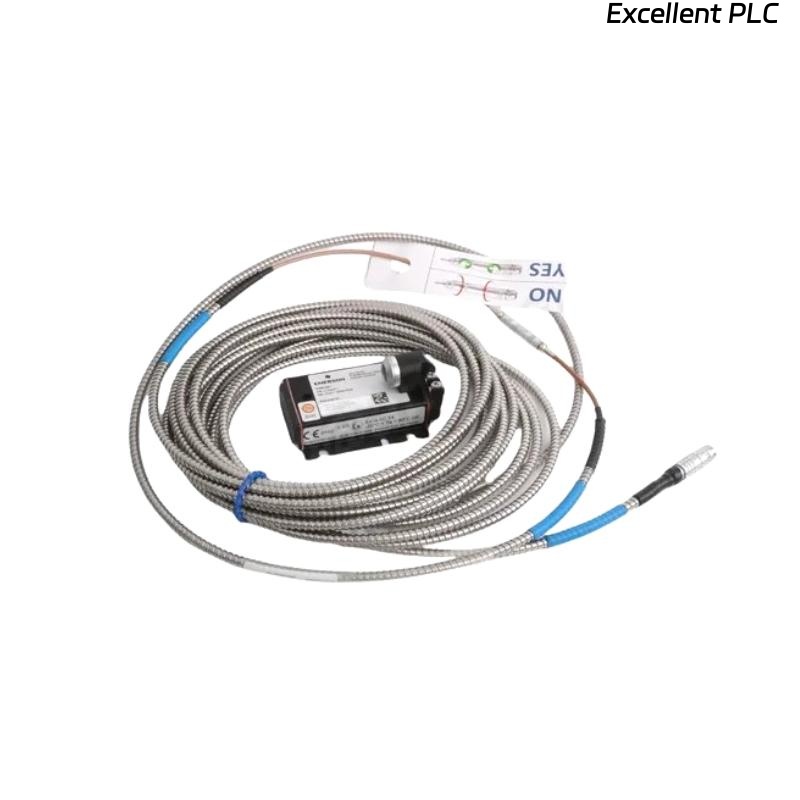

Product Overview

The Epro PR6424/010-120 + CON021 is a non-contact eddy current sensor system designed for highly accurate monitoring of shaft displacement, vibration, and axial position in rotating equipment. The system consists of the PR6424/010-120 probe with a 16 mm tip diameter, factory-paired with the CON021 converter, delivering industry-standard 4–20 mA output signals.

Built to withstand harsh industrial environments and comply with API 670 standards, the sensor is widely used in turbomachinery protection and condition monitoring systems across energy, oil & gas, chemical, and heavy processing industries. Its precision, rugged design, and compatibility with both legacy and modern control systems make it a preferred choice for critical rotating machinery applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Sensor Model | PR6424/010-120 |

| Converter Model | CON021 |

| Measurement Principle | Eddy current (non-contact displacement sensing) |

| Measurement Range | 0 – 3 mm |

| Sensor Head Diameter | 16 mm |

| Output Signal | 4 – 20 mA (via CON021) |

| Frequency Response | 0 – 10 kHz (-3 dB) |

| Linearity Error | < ±1% of Full Scale Output (FSO) |

| Temperature Range (Probe) | -35°C to +180°C |

| Temperature Range (Converter) | -35°C to +85°C |

| Storage Temperature | -40°C to +100°C |

| Material (Probe Housing) | Stainless Steel (AISI 316 or equivalent) |

| Cable Type | Coaxial, high-temperature insulated |

| Cable Length (Factory Calibrated) | 5 m, 7 m, 9 m, or custom lengths |

| Pressure Resistance | Up to 100 bar |

| Connector Type | MIL-C standard or optional HT connector |

| Protection Class | IP65 (standard), IP68 (optional sealing) |

| Compliance | API 670, CE, optional ATEX / IECEx certifications |

| Weight | 0.32 kg |

Applications

The Epro PR6424/010-120 + CON021 sensor system is engineered for high-reliability industrial monitoring tasks, particularly for rotating machines that require continuous, precise data for both protection and performance optimization. Typical applications include:

-

Shaft radial vibration monitoring in steam turbines and gas turbines

-

Axial displacement measurement for thrust bearing wear or position control

-

Shaft eccentricity detection in high-speed compressors and motors

-

Condition-based monitoring systems for preventive maintenance

-

Turbomachinery protection in accordance with API 670 standards

-

Bearing and rotor dynamic behavior analysis

Industries utilizing this sensor include:

-

Power generation (thermal, nuclear, hydro)

-

Oil & Gas – refineries, LNG plants, upstream platforms

-

Petrochemical and chemical processing

-

Marine propulsion and offshore equipment

-

Cement and mining industries

-

Steel and paper manufacturing sectors

Advantages

-

High-Precision Eddy Current Technology

Ensures non-contact, stable measurement of shaft motion over long durations with minimal drift. -

Wide Temperature and Pressure Resistance

Withstands extreme heat and process conditions with minimal impact on signal integrity. -

4–20 mA Analog Output

Universally accepted signal format allows seamless integration into DCS, PLC, or condition monitoring systems. -

API 670 Compliant

Meets critical turbomachinery protection standards, ensuring reliability in safety-critical applications. -

Pre-calibrated Probe + Converter + Cable Assembly

Reduces installation time and eliminates the need for field recalibration. -

Compact and Durable Design

Stainless steel body with high ingress protection enables use in dusty, wet, or high-vibration environments. -

Broad Industry Compatibility

Compatible with a wide range of monitoring hardware including Epro, Bently Nevada, Vibro-Meter, and Emerson systems. -

Long Service Life

Engineered for continuous industrial operation with minimal maintenance.

Frequently Asked Questions (FAQ)

-

Can this sensor system be used in high-vibration environments like gas turbines?

Yes. It is specifically designed for shaft vibration and position monitoring in high-vibration rotating equipment. -

Is the 4–20 mA output signal linear across the full measurement range?

Yes. It provides a linear analog signal proportional to displacement from 0 to 3 mm. -

Can I order the probe and cable separately?

No. The probe, cable, and converter are factory-calibrated as a set and must be used together. -

What is the default cable length and can it be customized?

Standard lengths are 5, 7, and 9 meters, with custom lengths available on request. -

Is this sensor suitable for ATEX or IECEx hazardous environments?

Yes, optional ATEX-certified variants are available upon request. -

What types of materials can the sensor detect?

It is optimized for conductive materials like steel shafts and rotors. -

Is field calibration necessary?

No. Factory calibration ensures accuracy. Field recalibration is not typically needed unless components are replaced. -

Can it be used to measure both axial and radial displacement?

Yes. The sensor is versatile and can be installed for axial thrust or radial shaft displacement monitoring. -

Is there built-in overvoltage or EMI protection?

Yes. The CON021 converter includes protection circuitry suitable for industrial EMC environments. -

How is this sensor installed and mounted?

Typically mounted using threaded mounting holes or brackets. Alignment and standoff distance must match calibration values.

Related or Same Series Models

| Model | Tip Diameter | Range | Temperature Range | Application |

|---|---|---|---|---|

| PR6424/010-100+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Standard shaft vibration monitoring |

| PR6424/010-130+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Extended cable or signal conditioning use |

| PR6424/012-120+CON041 | 16 mm | 0–3 mm | -35°C to +200°C | High temp converter applications |

| PR6424/014-120+CON021 | 16 mm | 0–4 mm | -35°C to +180°C | Higher displacement range |

| PR6424/010-140+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Low noise version for precise machines |

| PR6424/01CS+CON021 | 16 mm | 0–3 mm | -35°C to +180°C | Compact sensor, short-form version |

Popular Models from the Epro Brand

| Model | Type | Function | Notes |

|---|---|---|---|

| MMS6110 | Monitoring System | Vibration and speed monitoring | Fully modular, scalable, API-compliant |

| PR6423/002-030+CON021 | Eddy Current Sensor | Compact 8 mm sensor for radial measurement | Widely installed in compressors |

| MMS3120/022-100 | Monitoring Module | Dual-channel monitoring for vibration | DIN-rail mountable, integrated output |

| PR9268/201-000 | Seismic Sensor | Velocity-based casing vibration sensor | Ideal for pump/motor housings |

| CON041 | Signal Converter | For PR6426 series, delivers 4–20 mA output | High signal fidelity and noise rejection |

| MMS6120 | Monitoring Rack | Multi-channel monitoring with relay outputs | Used in power plant automation |

Excellent PLC

Excellent PLC